Food additives for grain beverage

A technology for food additives and cereal beverages, applied in the field of cereal beverage stabilizers, can solve the problems of sticky gel taste, water separation, precipitation, etc., and achieve the effect of preventing water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of food additive for cereal beverage, each component and weight ratio are as follows, (total amount is 25Kg):

[0025] 40 parts of glyceryl monostearate; 15 parts of carrageenan; 15 parts of xanthan gum; 20 parts of guar gum; 10 parts of sodium citrate.

[0026] The preparation method of above-mentioned cereal beverage stabilizer:

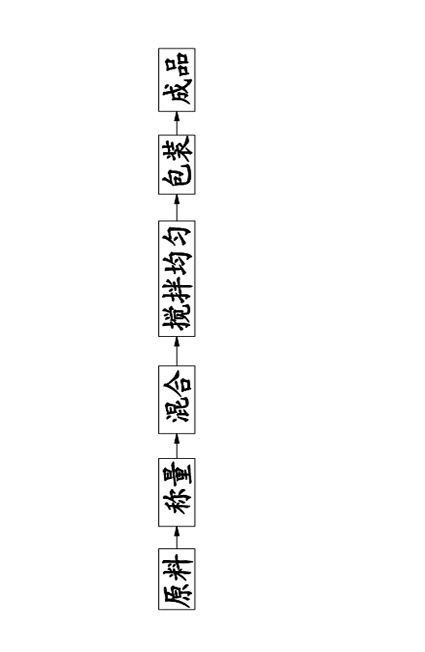

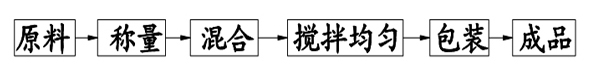

[0027] First, the glyceryl monostearate, carrageenan, xanthan gum, guar gum, sodium citrate and other components according to the ratio are mixed, and then stirred evenly to obtain the grain beverage stabilizer in a uniform powder state. Specific process such as figure 1 :

[0028] 1. Weighing: Weigh the above-mentioned components according to the proportioning weight requirements;

[0029] 2. Mixing: Add the weighed components into the double-helix conical mixer, start the machine and stir for 15 minutes, stop the machine, release about 25kg of base material from the outlet, and then add the released base material to...

Embodiment 2

[0042] Embodiment 2: a kind of food additive for cereal beverage, each component and weight ratio are as follows:

[0043] 50 parts of glyceryl monostearate; 13 parts of carrageenan; 14 parts of xanthan gum; 13 parts of guar gum; 10 parts of sodium citrate.

[0044] The preparation method of above-mentioned cereal beverage stabilizer is as figure 1 :

[0045]First, the glyceryl monostearate, carrageenan, xanthan gum, guar gum, sodium citrate and other components according to the ratio are mixed, and then stirred evenly to obtain the grain beverage stabilizer in a uniform powder state. The specific process is as follows:

[0046] 1. Weighing: Weigh the above-mentioned components according to the proportioning weight requirements;

[0047] 2. Mixing: Add the weighed components into the double-helix conical mixer, start the machine and stir for 15 minutes, stop the machine, release about 100 parts by weight of the base material from the discharge port, and then add the release...

Embodiment 3

[0055] Embodiment 3: a kind of food additive for cereal beverage, each component and weight ratio are as follows:

[0056] 48 parts of glyceryl monostearate; 15 parts of carrageenan; 15 parts of xanthan gum; 12 parts of guar gum; 10 parts of sodium citrate.

[0057] The preparation method of above-mentioned cereal beverage stabilizer is as figure 1 :

[0058] First, the glyceryl monostearate, carrageenan, xanthan gum, guar gum, sodium citrate and other components according to the ratio are mixed, and then stirred evenly to obtain the grain beverage stabilizer in a uniform powder state. The specific process is as follows:

[0059] 1. Weighing: Weigh the above-mentioned components according to the proportioning weight requirements;

[0060] 2. Mixing: Add the weighed components into the double-helix conical mixer, start the machine and stir for 15 minutes, stop the machine, release about 100kg of base material from the outlet, and then add the released base material to the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com