Method for controlling injection speed of screw of injection molding machine

A technology of injection molding machine screw and injection speed, which is applied in the field of injection molding engineering, can solve the problems that the injection speed of injection molding machines cannot be effectively controlled, and achieve the effects of effective tracking, low identification cost, and convenient online calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

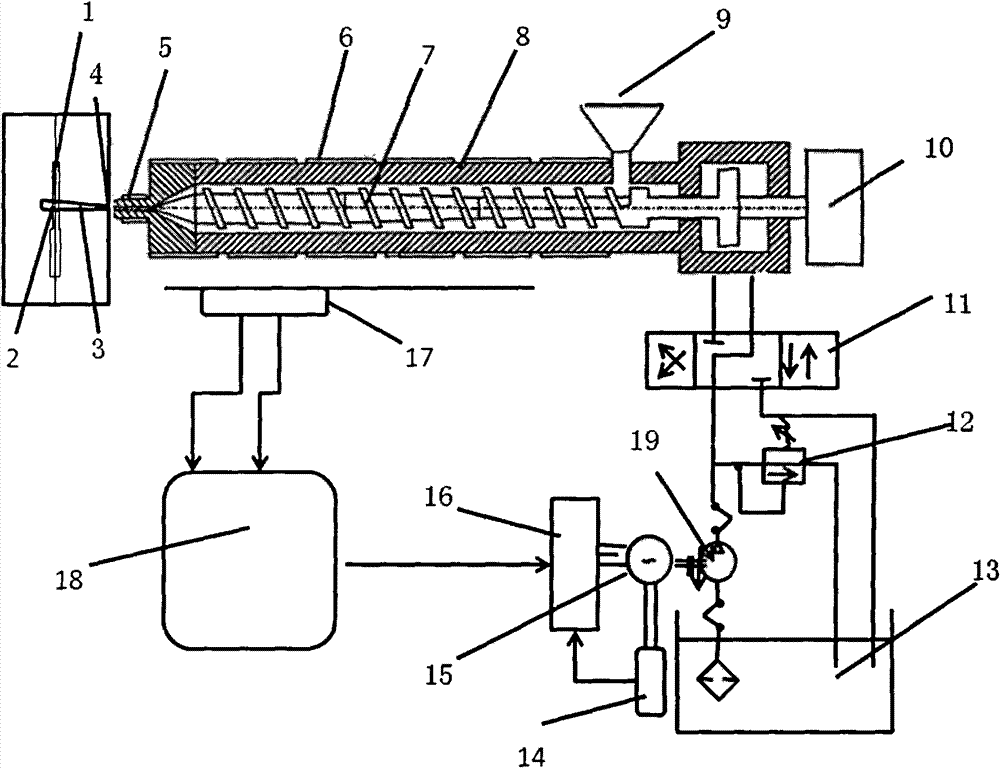

[0057] The present invention can adopt the oil-electric hybrid energy-saving injection molding machine produced by Ningbo Haitai Machinery Manufacturing Co., Ltd., and its model is HTL68 / JD. In the present invention, the closed-loop control circuit for the screw injection speed is as follows: figure 1 shown. Among them, AI and AO are the analog input and output ports of the data acquisition board (PCI1710HG / PCI1720); S600 is the permanent magnet synchronous motor driver; PMSM is the permanent magnet synchronous motor; P and V respectively represent the position measurement output signal of the MTS sensor and Speed measurement output signal. The high-speed data acquisition device of the present invention can adopt the high-speed data acquisition device formed by the PXI-1042Q chassis of NI Company and the NI PXI-5122 high-speed digitizer module and LABWIEW software, also can adopt the PCI1710HG and PCI1720 data acquisition board card of Advantech Company And a high-speed da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com