Compound early strength antifreezing agent of unshaped refractory for aluminate cement

A technology of aluminate cement and refractory materials, which is applied in the field of composite early-strength antifreeze, and can solve problems such as skin bursting and poor lining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The composition ratio of each component of antifreeze is: ethylene glycol: urea: lithium hydroxide: sodium dodecylsulfonate: FS20: water = 159: 68: 27: 3: 30: 313.

[0030] Concrete preparation steps are as follows:

[0031] In a flask in a water bath at 40°C, add urea to 200g of water and stir thoroughly for 5 to 10 minutes. After the urea is fully dissolved, add lithium hydroxide and FS20 water reducer, stir for 10 minutes to fully dissolve, and then add ethylene glycol in sequence. Alcohol and sodium lauryl sulfate, and finally add the remaining water, stir well to make it uniform, that is, complete the preparation of this antifreeze, and obtain a slightly turbid light brown solution. The whole process takes 20 to 30 minutes.

[0032] The test process and results of using the antifreeze:

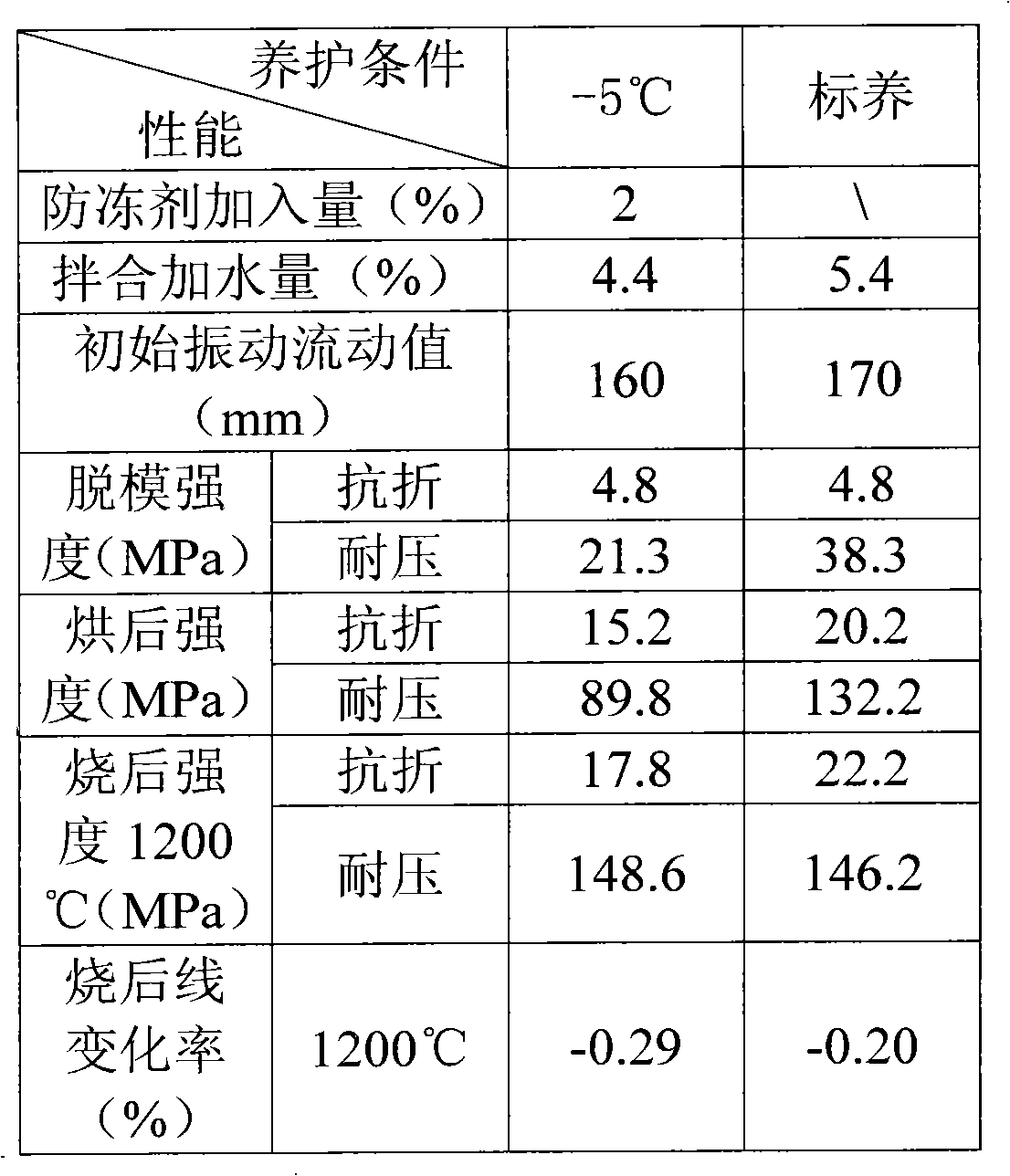

[0033] The test materials were prepared according to the actual production of bauxite low cement castable formula. In order to simulate the actual construction environment, the ...

Embodiment 2

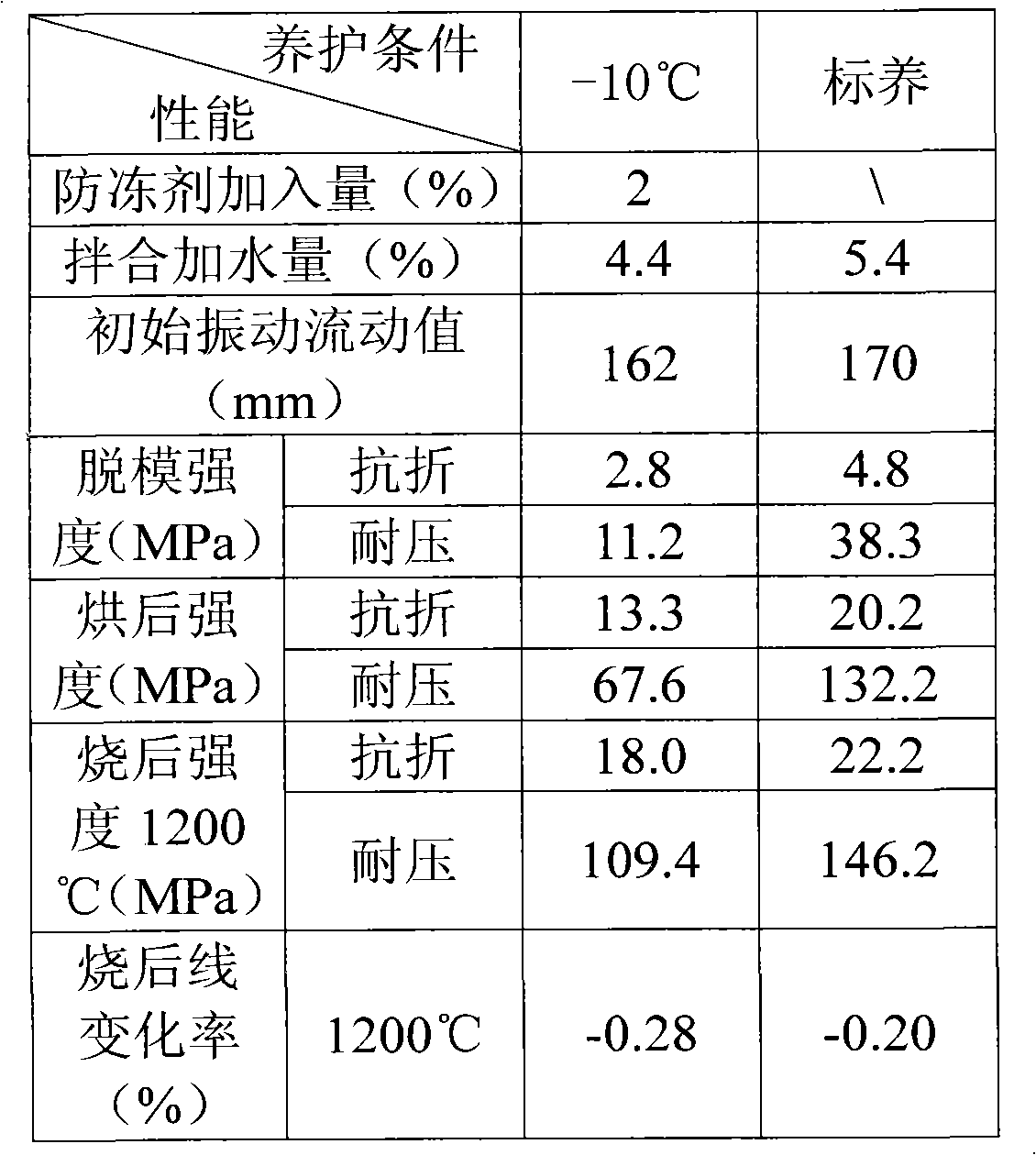

[0041] The composition ratio of each component of antifreeze is: ethylene glycol: urea: lithium hydroxide: sodium dodecylsulfonate: sodium tripolyphosphate: water = 175.5: 88.5: 30: 2: 28: 276. It is used in the construction of castables under the ambient conditions of -10°C. Antifreeze preparation process is the same as embodiment 1. The castable test process is the same as in Example 1 except that the test operating environment is -10°C and the 48-hour curing environment after molding is -10°C. The test data records are shown in Table 3:

[0042]Table 3 The test data after adding this antifreeze and standard curing under the test condition of -10°C

[0043]

[0044] As can be seen:

[0045] (1) Under the test condition of -10°C, the castable uses the antifreeze agent of this example, and reaches a certain safe demoulding strength after 2 days of curing, indicating that this product meets the requirements of antifreeze and early strength, and can shorten the constructio...

Embodiment 3

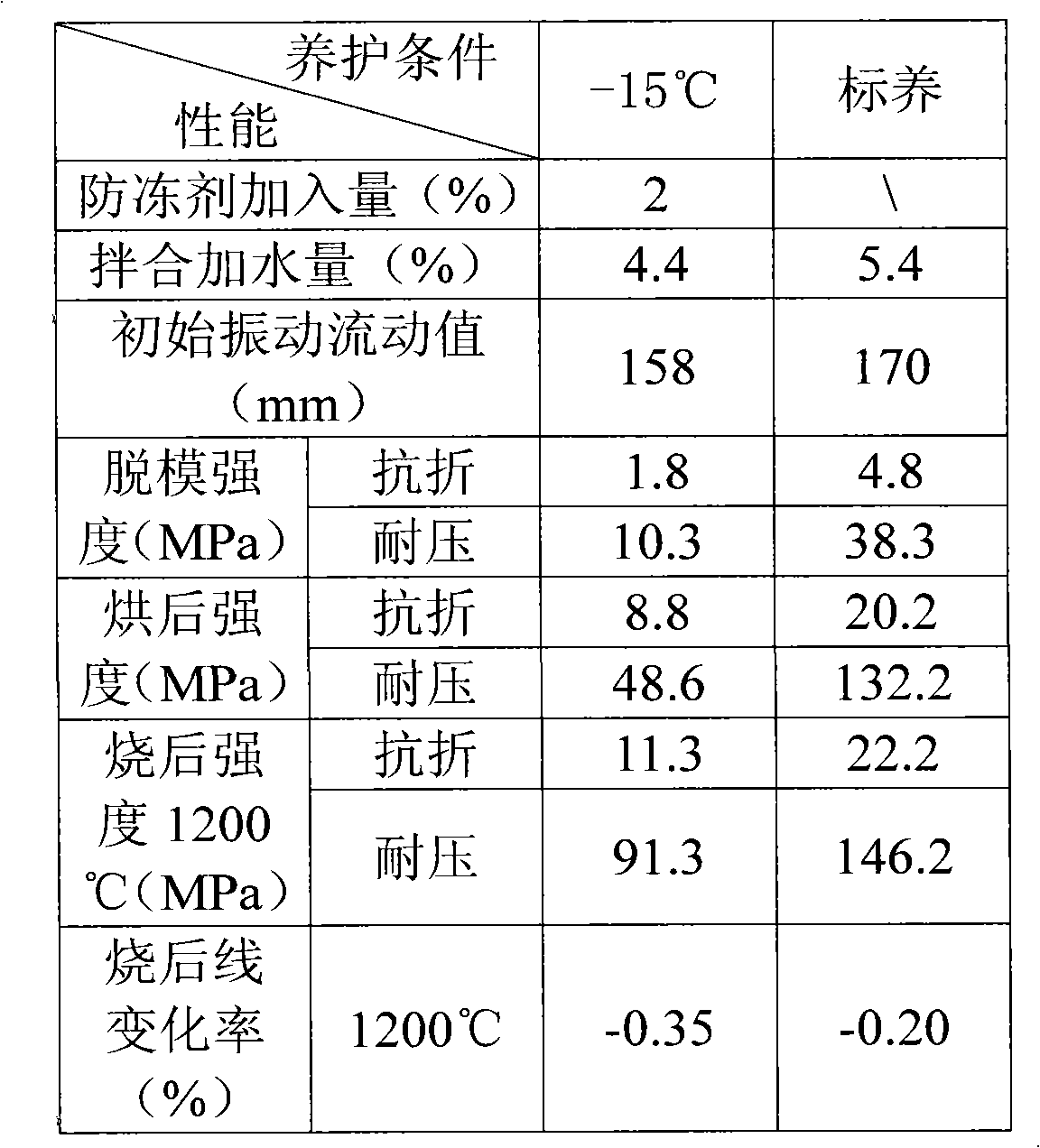

[0049] The weight composition ratio of each component of the antifreeze agent is: ethylene glycol: urea: sodium aluminate: emulsifier OP-10: FS20: water = 202.5: 90: 45: 3: 30: 229.5. It is used in the construction of castables under the environmental conditions of -15°C. Antifreeze preparation process is the same as embodiment 1. The castable test process is the same as in Example 1 except that the test operating environment is -15°C and the 48-hour curing environment after molding is -15°C. The test data records are shown in Table 4:

[0050] Table 4 The test data after adding this antifreeze and standard curing under the test condition of -15°C

[0051]

[0052] As can be seen:

[0053] (1) Under the test condition of -15°C, the castable uses the antifreeze agent of this example, and reaches a certain safe demoulding strength after 2 days of curing, indicating that this product meets the requirements of antifreeze and early strength, and can shorten the construction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com