Method for separating azeotropic mixture of ethyl methyl ketone and water through variable-pressure rectification

A technology of pressure swing rectification and methyl ethyl ketone, which is applied in the field of chemical distillation and purification, can solve the problem of high energy consumption, and achieve the effect of improving product purity, reducing energy consumption, and reasonable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

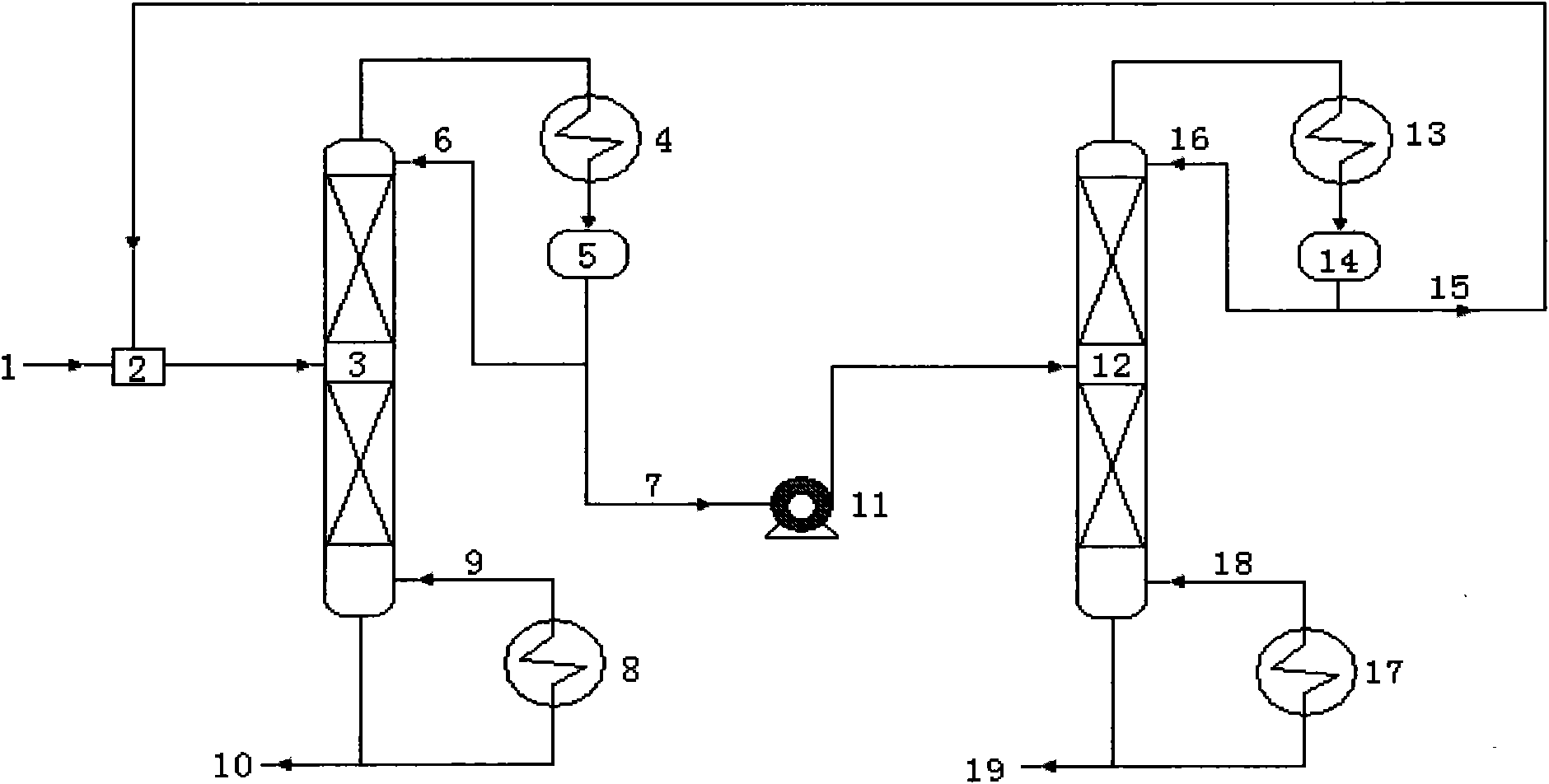

Method used

Image

Examples

Embodiment 1

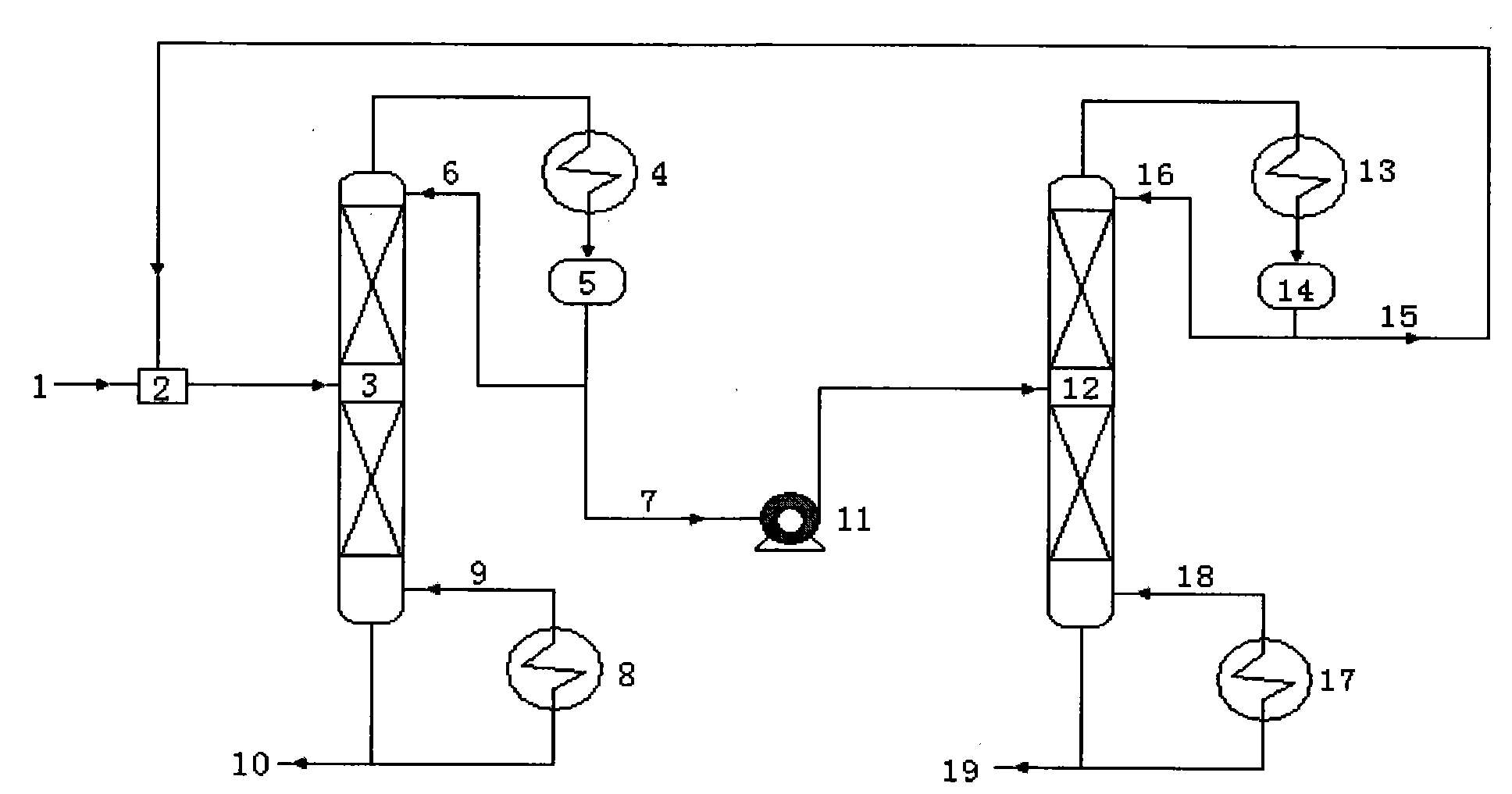

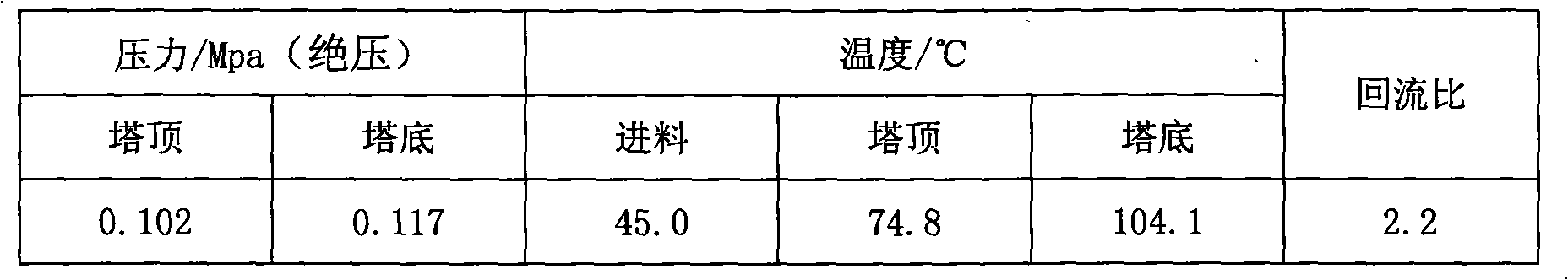

[0025] The feed flow rate is 2500kg / h, the temperature is 45°C, the pressure is 0.15Mpa (absolute pressure), and the composition: 32% methyl ethyl ketone and 68% water. The return flow rate is 657.7kg / h. Atmospheric pressure tower diameter 800mm, 32 theoretical plates, feed in the 12th block, packed with 9.5m BX500 structured wire mesh corrugated packing; pressurized tower diameter 400mm, 38 theoretical plates, feed in the 16th block, packed BX500 inside Structured wire mesh corrugated packing 11.2m.

[0026] The operating process parameters of the towers are shown in Table 1 and Table 2, the composition of the top and bottom materials of each tower are shown in Table 3, and the feeds of each tower and the flow rate of the top and bottom materials are shown in Table 4. It can be seen that by adopting the variable pressure rectification method of the present invention, the purity of methyl ethyl ketone after purification reaches 99.9%, and the yield reaches more than 99.8%.

[002...

Embodiment 2

[0036] The feed flow rate is 3200kg / h, the temperature is 45°C, the pressure is 0.15Mpa (absolute pressure), and the composition: methyl ethyl ketone 45% and water 55%. The return flow rate is 1183kg / h. The diameter of the atmospheric tower is 950mm, and the diameter of the pressurized tower is 500mm. Other conditions are the same as in Example 1. The operation results are shown in Table 5 and Table 6. After refining, the purity of methyl ethyl ketone reaches more than 99.9%, and the yield is 99.9%.

[0037] Table 5 The composition of the top and bottom materials of each tower

[0038]

[0039] Table 6 The feed of each tower and the material flow at the top and bottom of the tower

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com