Continuous production technique for ethoxyl ethylene diamine and reaction kettle thereof

A technology of hydroxyethylethylenediamine and production process, which is applied in the production technology field of continuous production of hydroxyethylethylenediamine, can solve the problems of high energy consumption, large circulation amount of by-reaction product raw materials, and high liquid-gas molecular ratio. , to achieve the effect of reducing energy consumption and by-products, the production process is simple and convenient, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

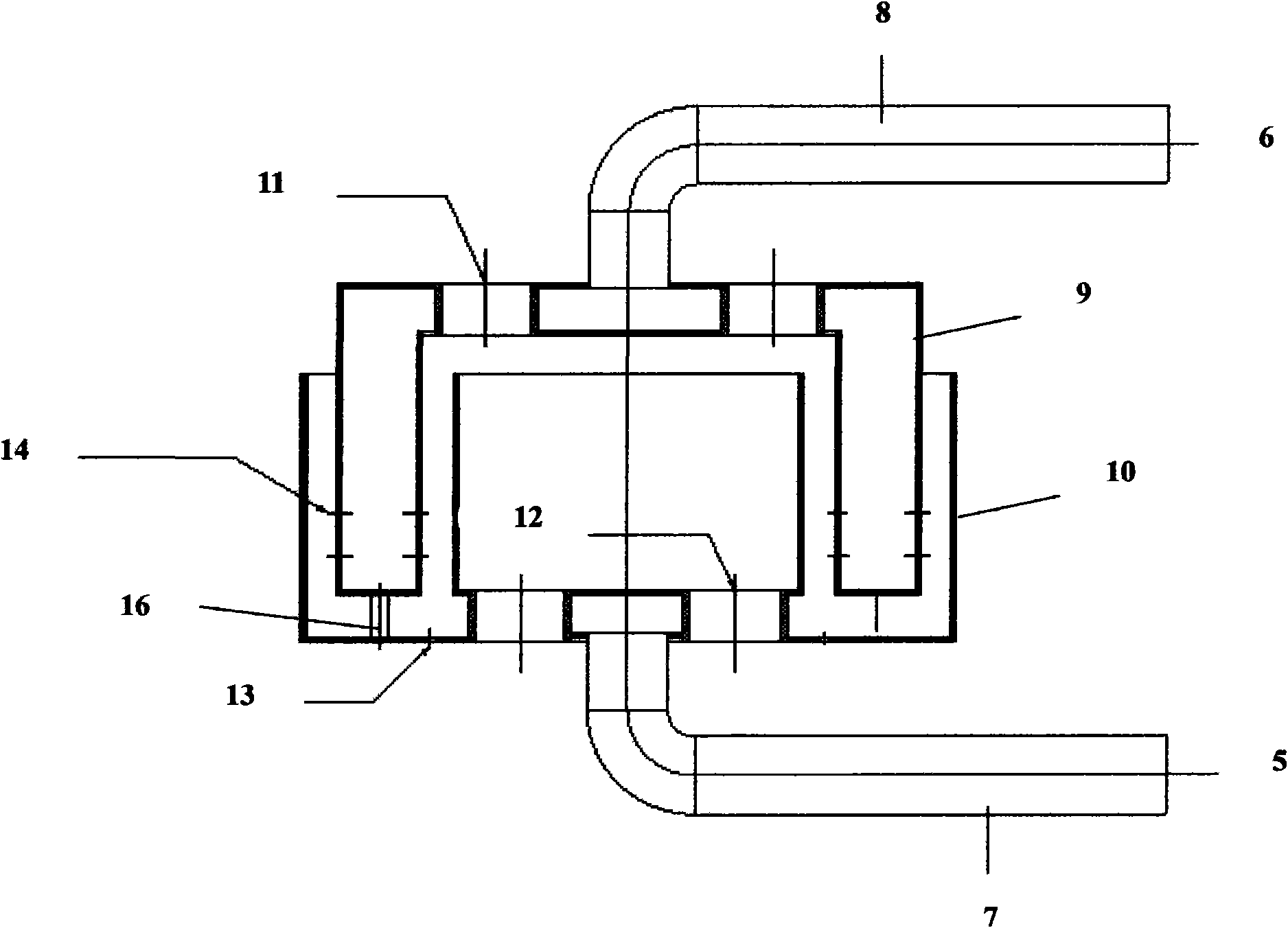

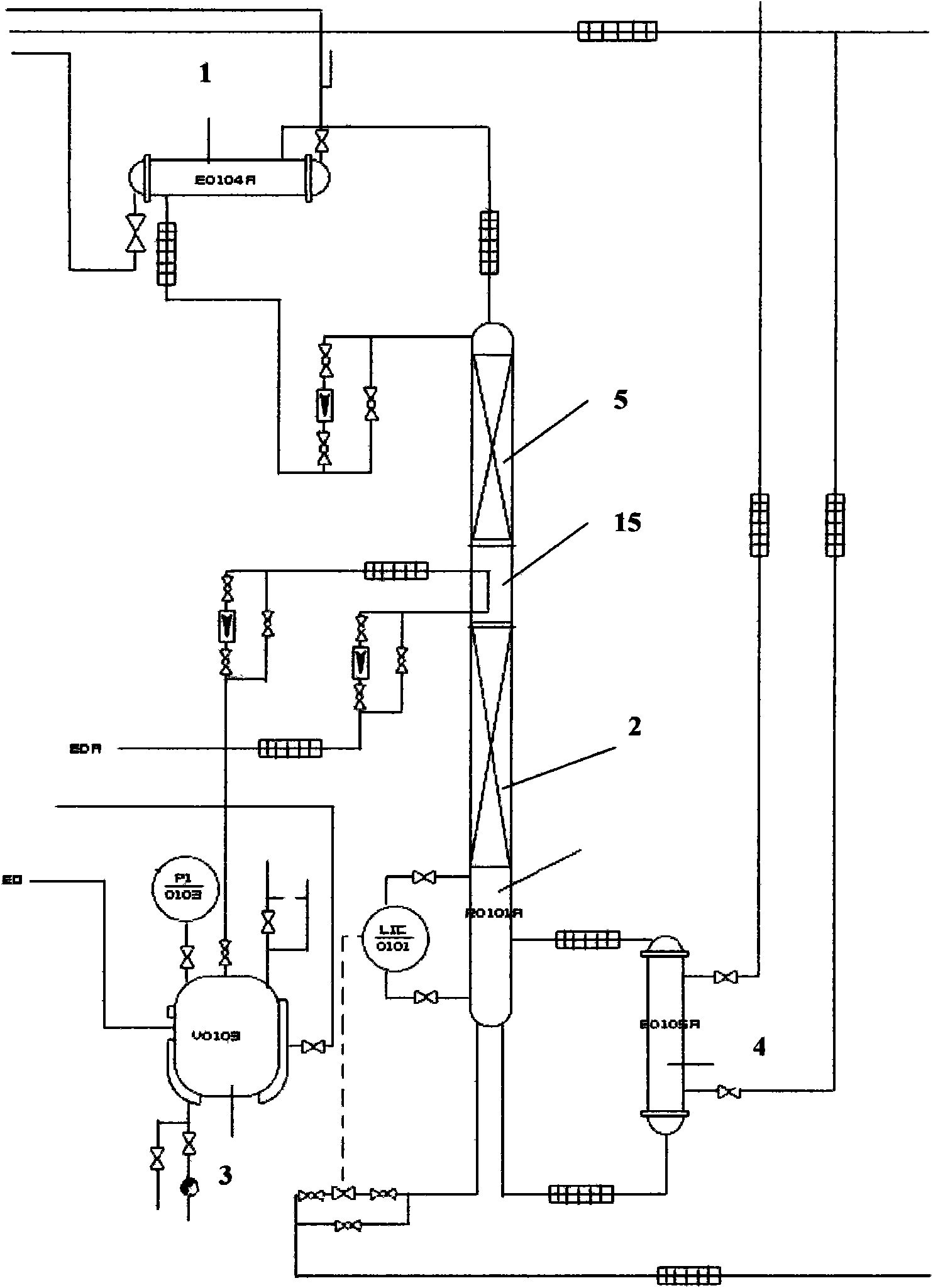

[0049] 1 is the top decondenser, 2 is the stripping section of the rectification reaction tower, 3 is the ring ethyl buffer tank, 4 is the reboiler of the tower kettle, 5 is the rectification section of the rectification reaction tower, and 15 is the reaction of the rectification reaction tower 5 is the first inlet, 6 is the second inlet, 7 is the first central tube, 8 is the second central tube, 9 is the gas collection ring, 10 is the liquid collection ring, 11 is the air outlet, 12 is the reaction liquid outlet , 13 is a tear hole, 14 is a ring B uniform distribution hole, 15 is a reactor, and 16 is a round copper fixed distance.

[0050] The raw material ethylenediamine 600KG (99%) is poured into the high-level metering tank, and enters the ethylenediamine heater to be heated to 110°C through the potential difference gravity flow (not shown in the figure), and the flow rate is controlled by the flow meter to 1200L / H, along the first inlet 5 enters the first central pipe 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com