Special drilling machine applied to coal mine getting working face

A technology for excavating working face and drilling rig, applied in the field of mining machinery, can solve the problems of poor safety performance and large space occupied, and achieve the effects of prolonging service life, improving safety performance and shortening loading and unloading time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

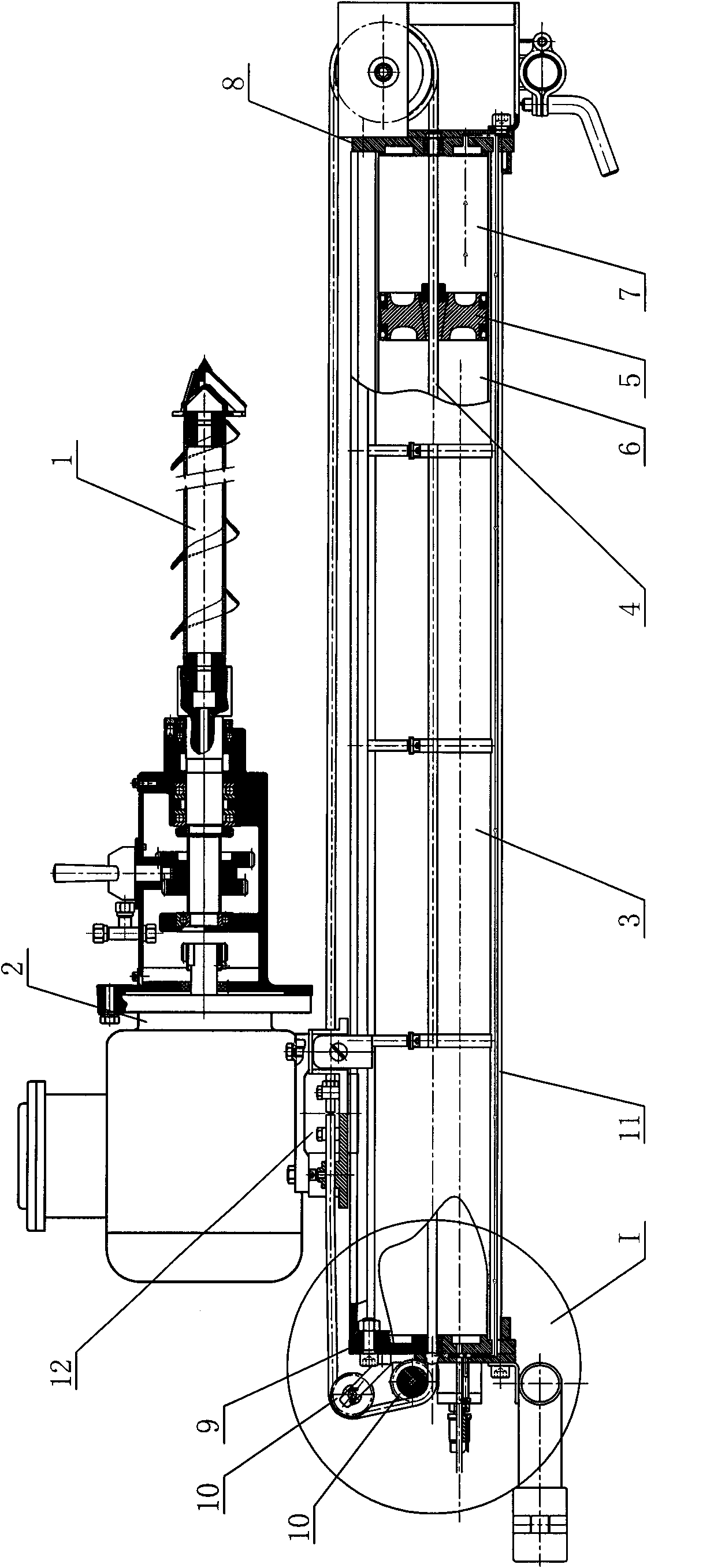

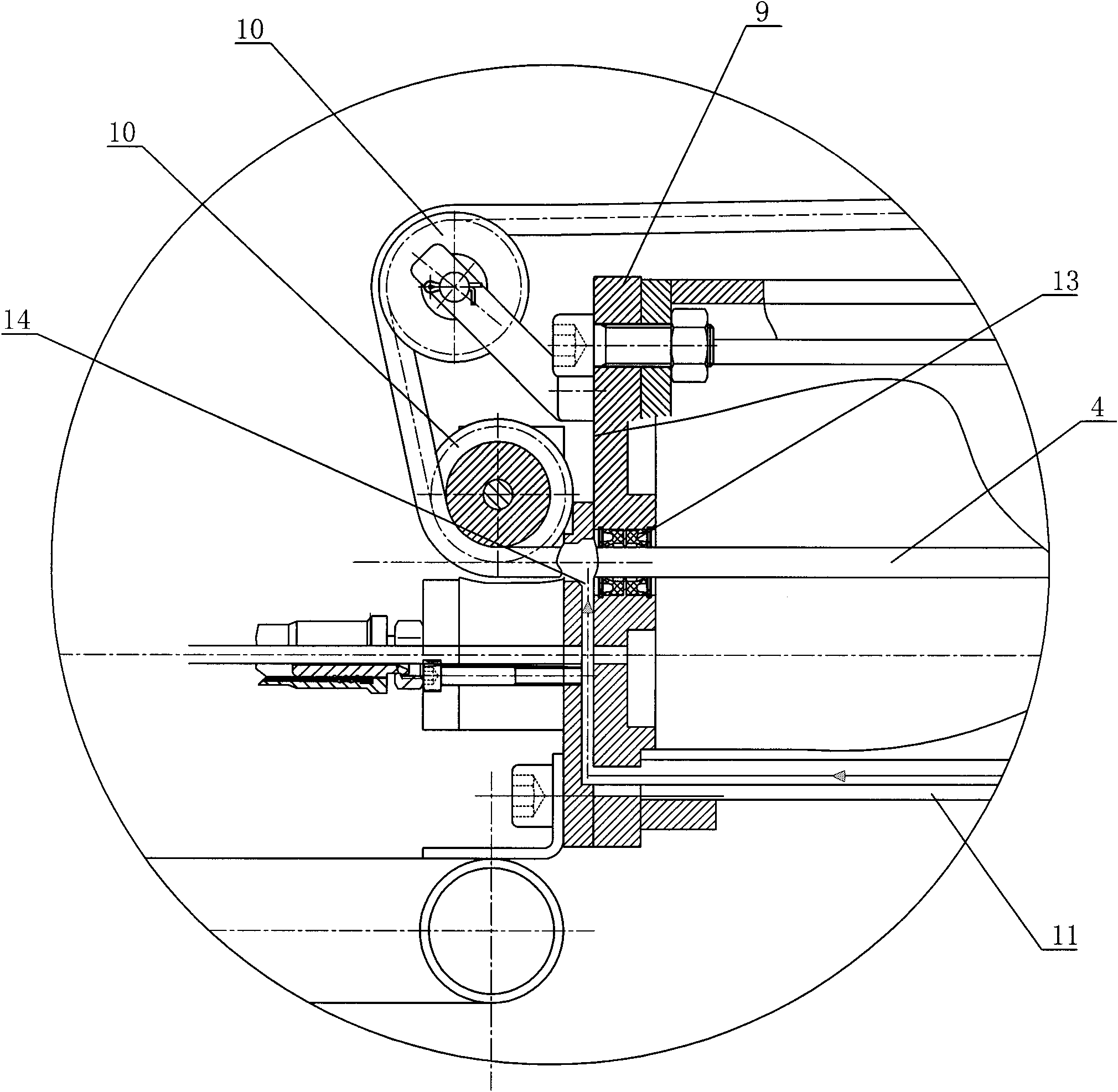

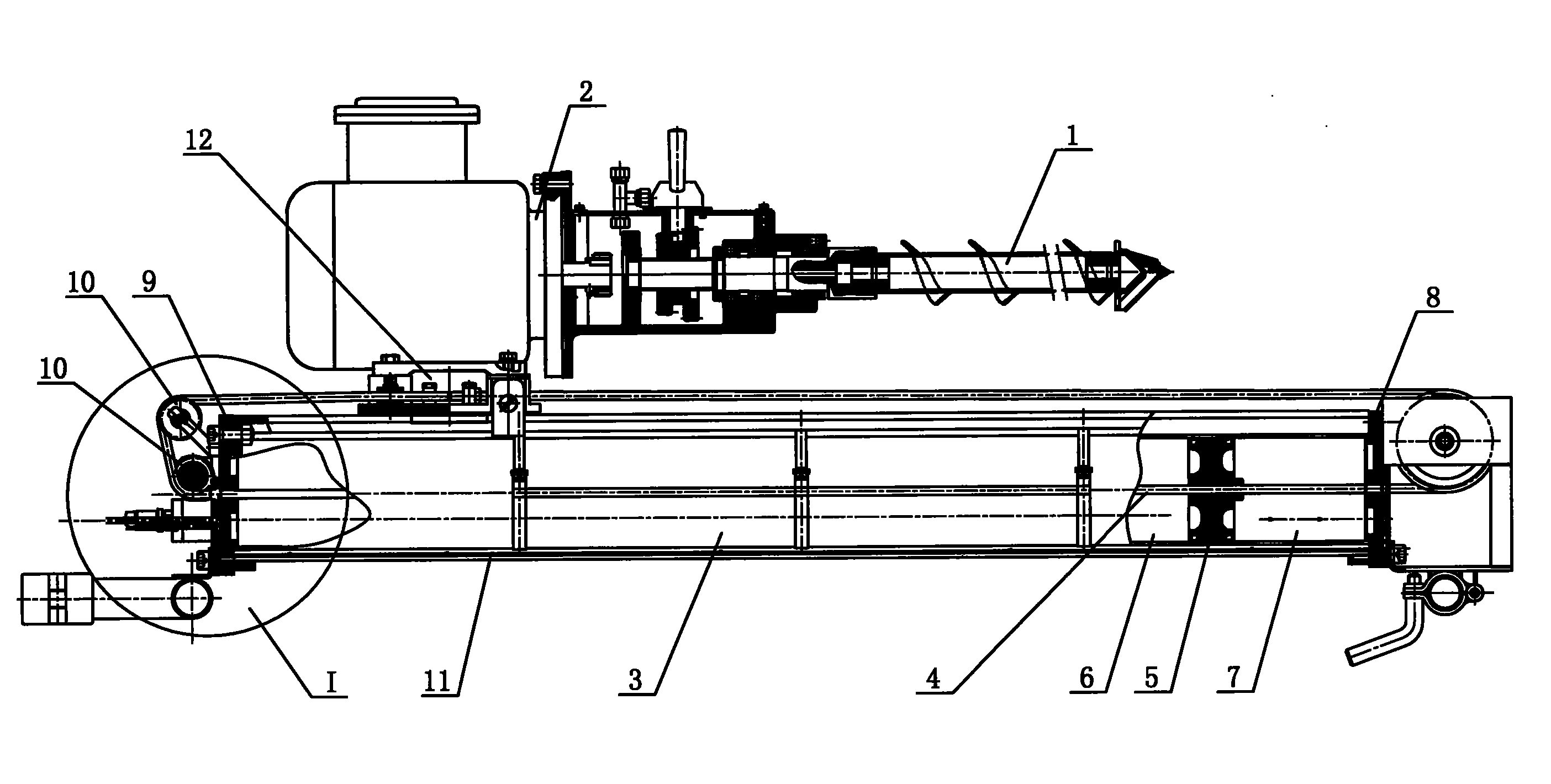

[0011] The accompanying drawings show the technical solutions and embodiments of the present invention. The relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0012] With reference to the drawings, the special drilling rig applied to coal mining face includes a drill rod 1, a power head 2, and a propulsion device. The propulsion device includes a cylinder, the cylinder includes a cylinder block 3, a piston 5, and a wire rope 4. The steel wire rope 4 is wrapped with a plastic coating layer, which can be polyvinyl chloride material or polytetrafluoroethylene material. The piston 5 is movably arranged in the cylinder block 3 and fixedly connected with the rope 4, and After the piston 5 is connected, the two ends of the rope 4 respectively pass through the front and rear end covers 8 and 9 of the cylinder block 3, and a good seal is formed between the outer circle of the rope 4 and the lip-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com