Vehicle exhaust muffler pasted with high temperature-resistant sound-absorbing layer and manufacturing method thereof

A technology for automobile exhaust and high temperature resistance. It is applied in the direction of exhaust devices, noise reduction devices, machines/engines, etc. It can solve the problems of sound absorption performance and engine power loss, low engine power loss, and high cost, and achieve excellent absorption. Acoustic effect, improvement of vibration mode, effect of consuming sound transmission energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

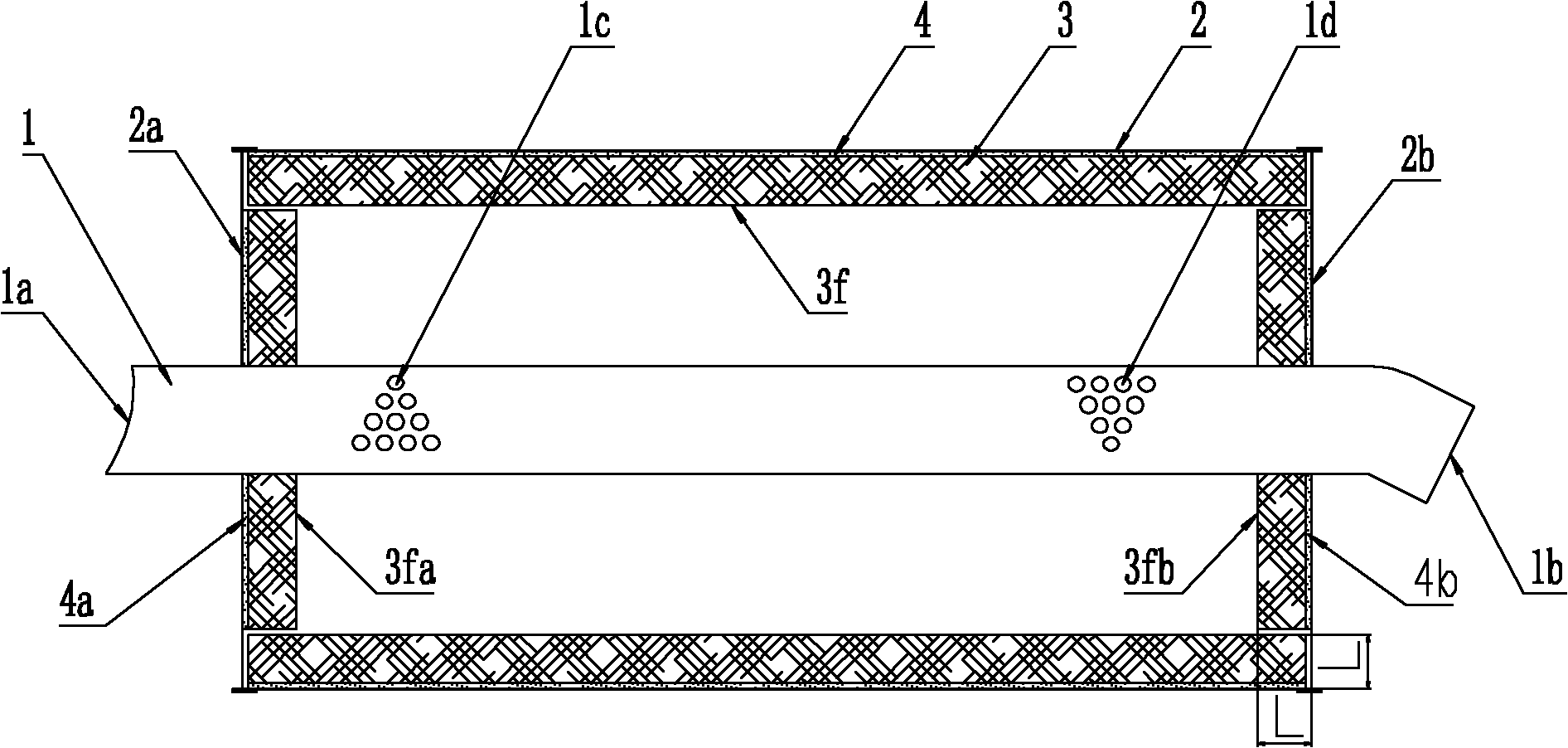

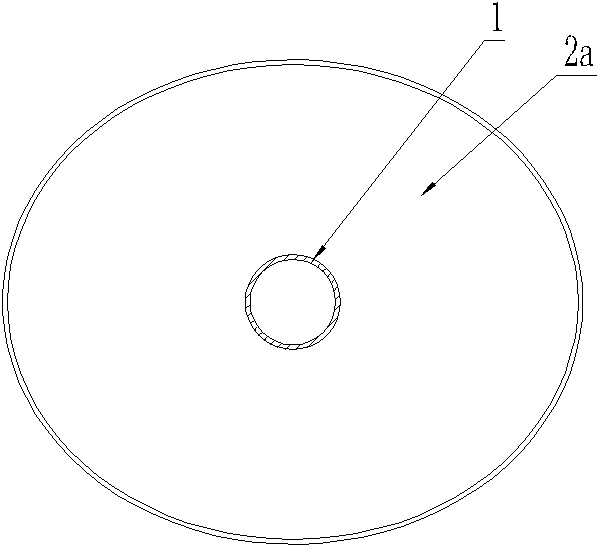

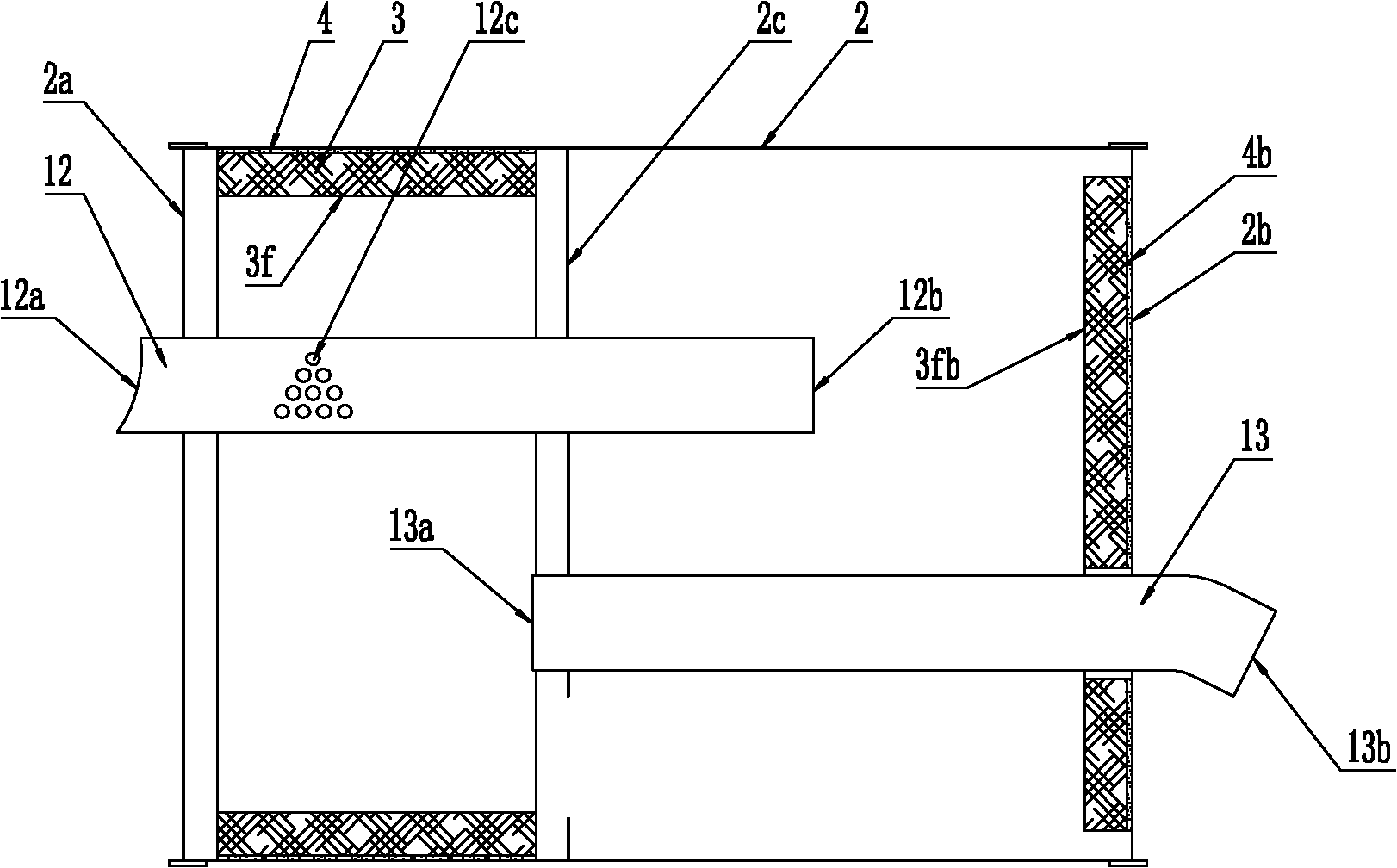

[0028] refer to Figure 1 ~ Figure 4 , an automobile exhaust muffler pasted with a high-temperature-resistant sound-absorbing layer, comprising an exhaust pipe 1 and a housing, the housing comprising a cylinder shell 2, a left cover 2a and a right cover 2b, the left cover 2a and the The left end opening of the cylinder shell 2 is sealed and connected, and the right cover plate 2b is sealed and connected with the right end opening of the cylinder shell 2. The exhaust pipe 1 passes through the holes of the left cover plate and the right cover plate in turn, and is located in the cylinder There are at least two through holes on the pipe wall of the exhaust pipe in the shell 2, and the inner wall of the shell is coated with a high temperature resistant adhesive layer 4, on which a high temperature resistant sound-absorbing Material layer 3.

[0029] Further, the surface of the high-temperature-resistant sound-absorbing material layer 3 is in the form of pores, bumps or hair bundl...

Embodiment 2

[0039] refer to Figure 1 ~ Figure 4 , a method of manufacturing an automobile exhaust muffler pasted with a high-temperature-resistant sound-absorbing layer, the method of manufacturing comprises the following steps:

[0040] (1) Clean and dry the inner surface of the shell;

[0041] (2) Spraying a high-temperature-resistant adhesive on the inner wall surface of the shell to form a high-temperature-resistant adhesive layer;

[0042] (3) Paste a heat-resistant sound-absorbing material layer on the high-temperature-resistant adhesive layer, and solidify and form it.

[0043] The manufacturing method further includes the step: (4), drying and curing the high-temperature-resistant sound-absorbing material layer, using an airflow drying method with a drying temperature of 50-155°C.

[0044] The high-temperature-resistant sound-absorbing material layer is high-temperature-resistant inorganic fibers, and the density of the high-temperature-resistant inorganic fibers is between 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com