Lithium bromide refrigerating machine capable of recycling heat energy by utilizing heat pump

A technology for recovering heat energy and lithium bromide, which is applied in the direction of refrigerators, heat pumps, refrigeration components, etc., can solve the problems of not being fully utilized, and achieve the effects of comprehensive development and utilization, increasing evaporation temperature, and improving refrigeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

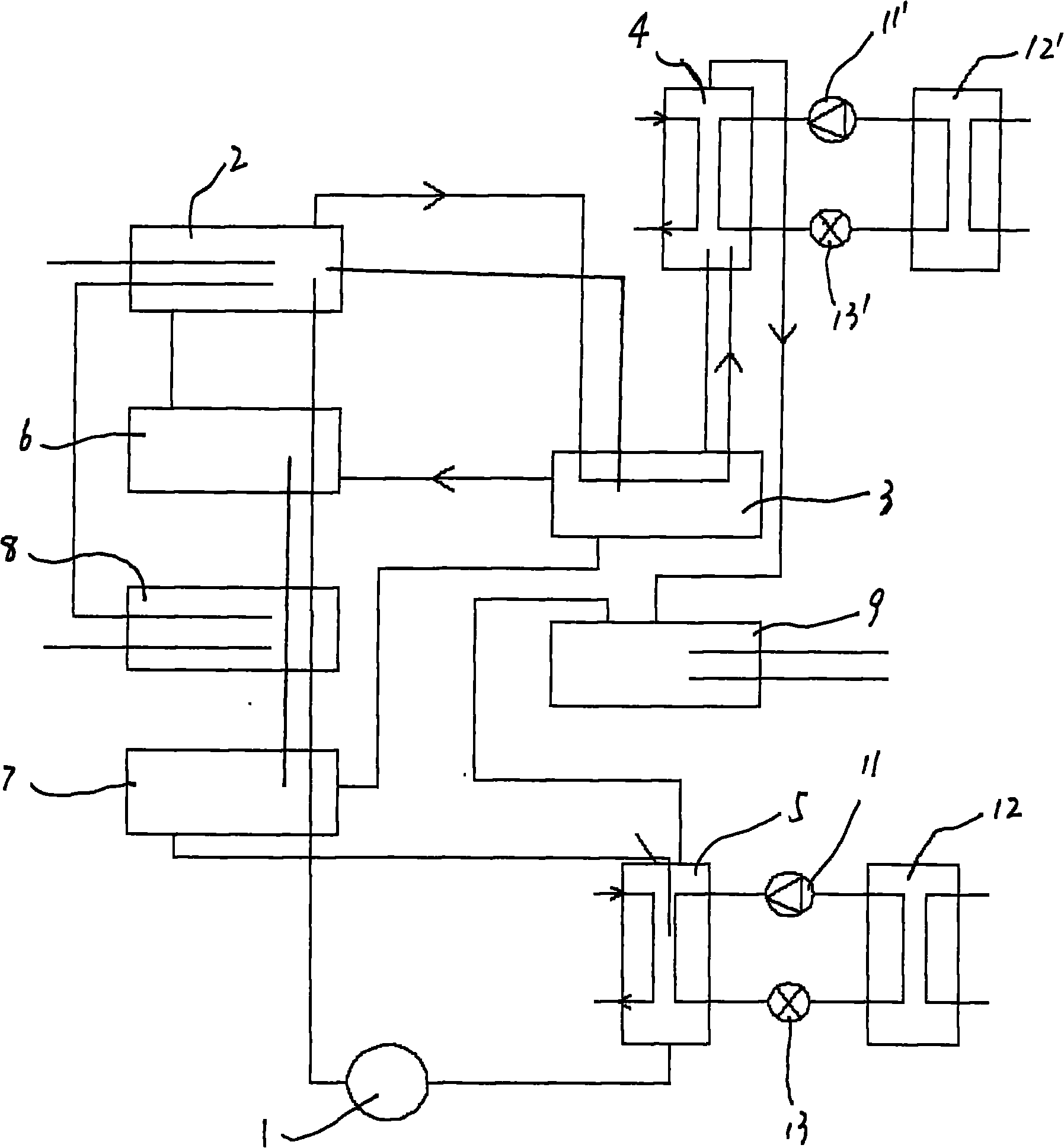

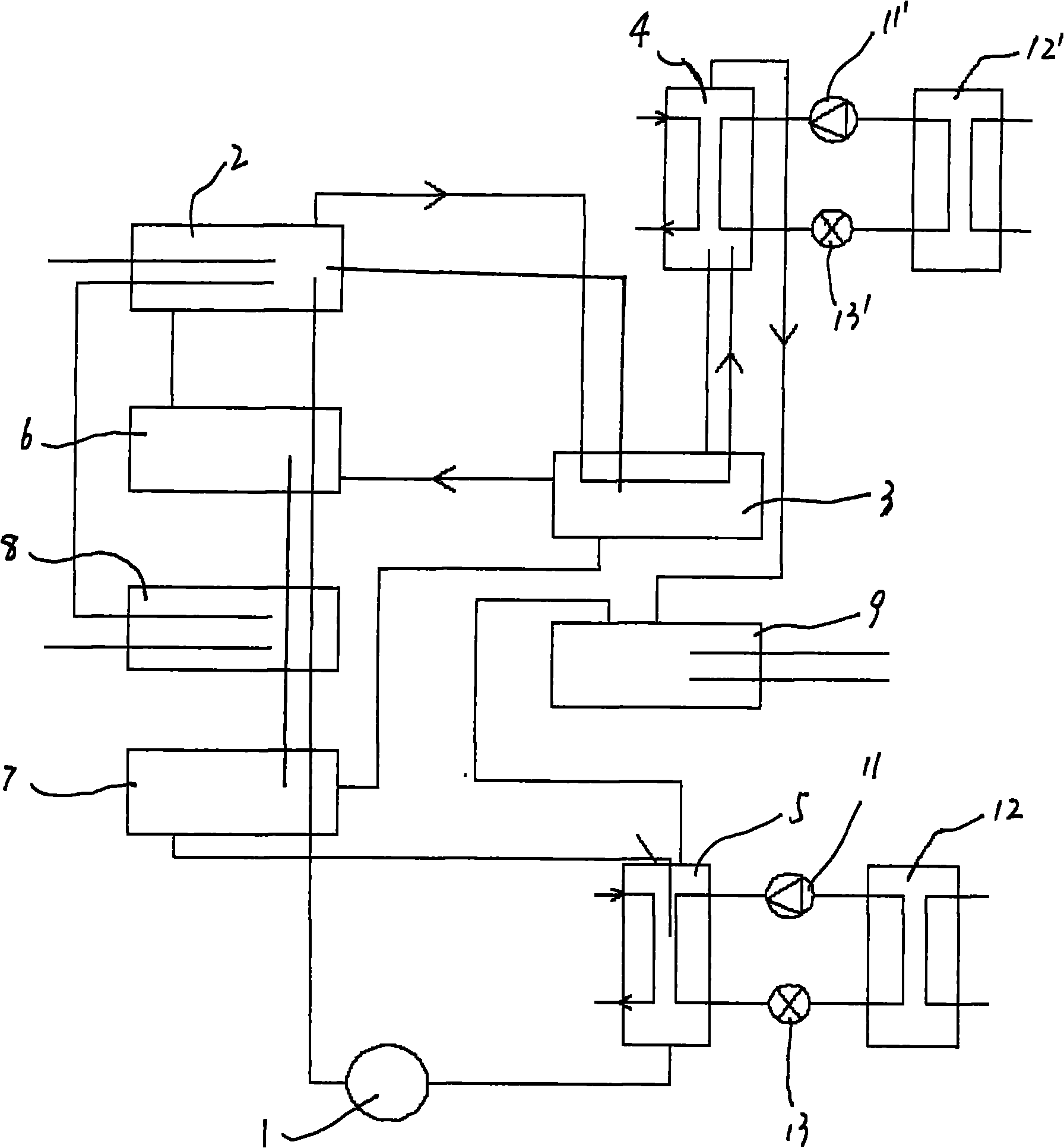

[0021] Such as figure 1 As shown, a lithium bromide refrigerator using a heat pump to recover heat energy includes a high-pressure generator 2, a low-pressure generator 3, an evaporator 9, an absorber 5, a condenser 4, a high-temperature heat exchanger 6, a low-temperature heat exchanger 7, and a solution Pump 1, refrigerant pump (not shown in the figure), control system and pipelines and valves connecting various components, wherein the refrigerant vapor outlet of high-pressure generator 2 is connected with the refrigerant vapor inlet of low-pressure generator 3, and the high-pressure The intermediate concentrated solution outlet of the generator 2 is connected to the intermediate concentrated solution inlet of the high-temperature heat exchanger 6, and the refrigerant water outlet of the condenser 4 is connected to the refrigerant water inlet of the evaporator 9 through a U-shaped tube (not shown in the figure) , the low-pressure generator 3 and the condenser 9 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com