Spring operation mechanism for high-voltage breaker

A high-voltage circuit breaker and operating mechanism technology, which is applied in the field of power transmission and transformation, can solve the problems of unstable opening and closing time, inconvenient installation and debugging, and difficult manufacturing process, and achieves easy purchase and maintenance, stable mechanical characteristics, and small volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

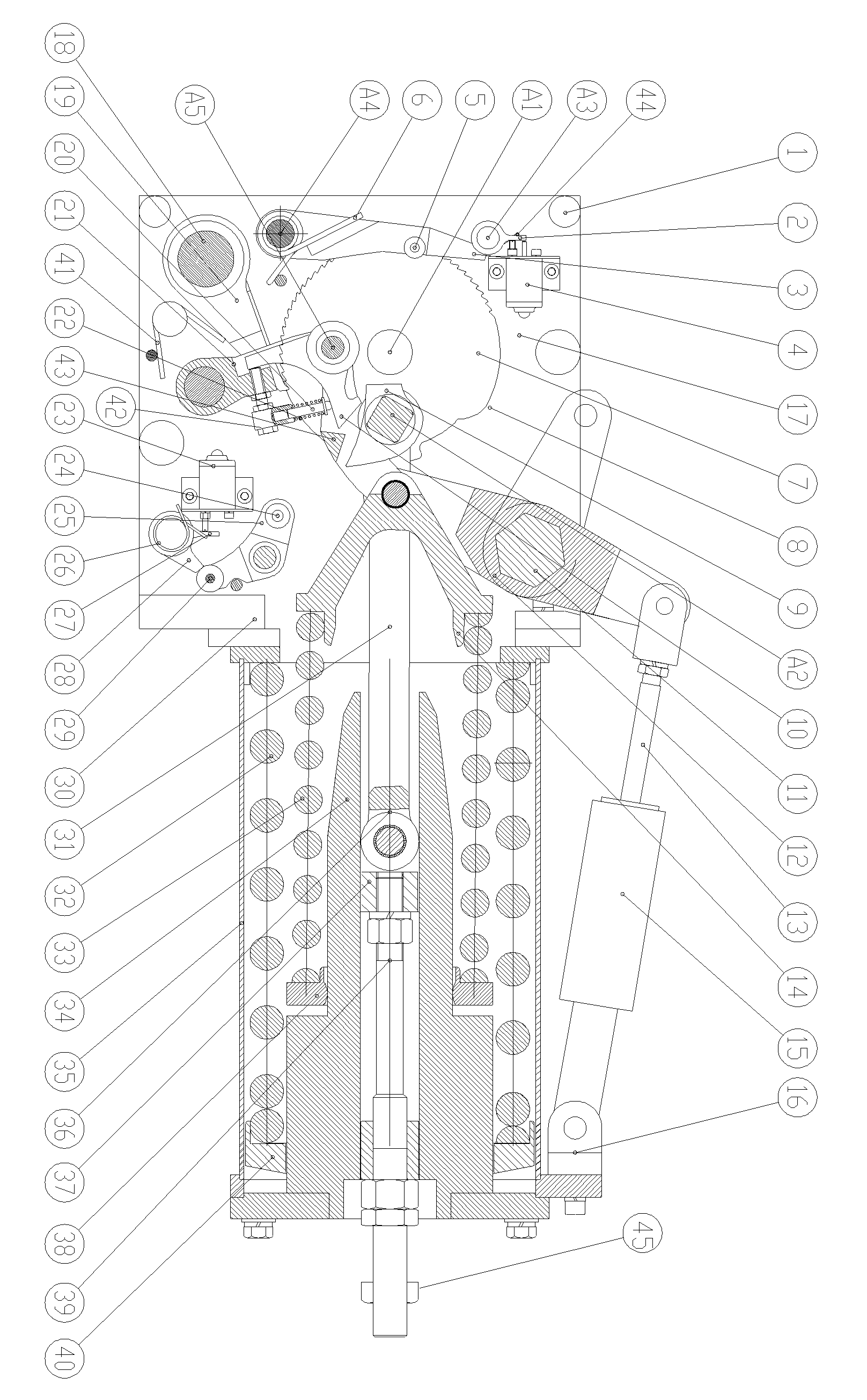

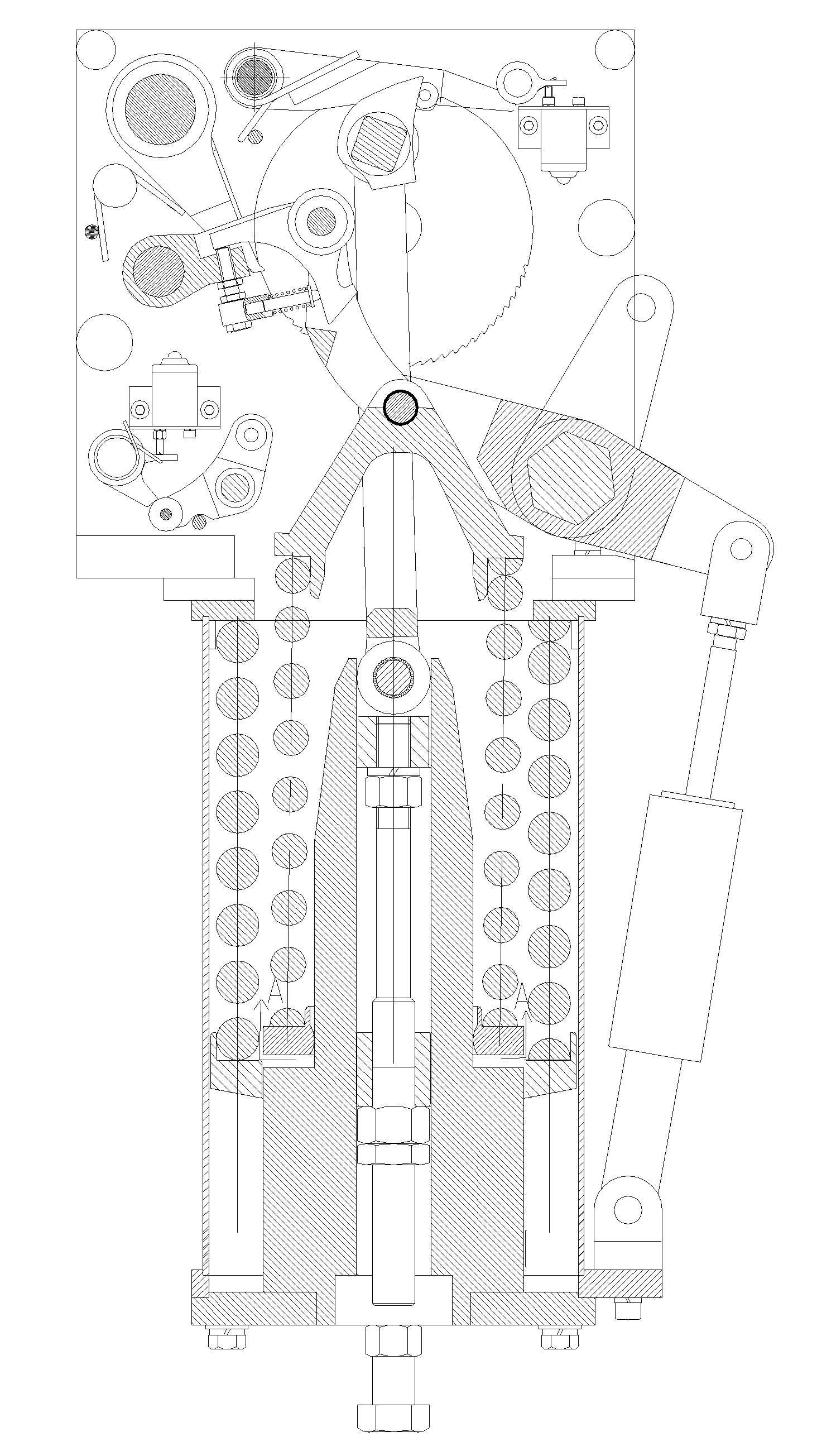

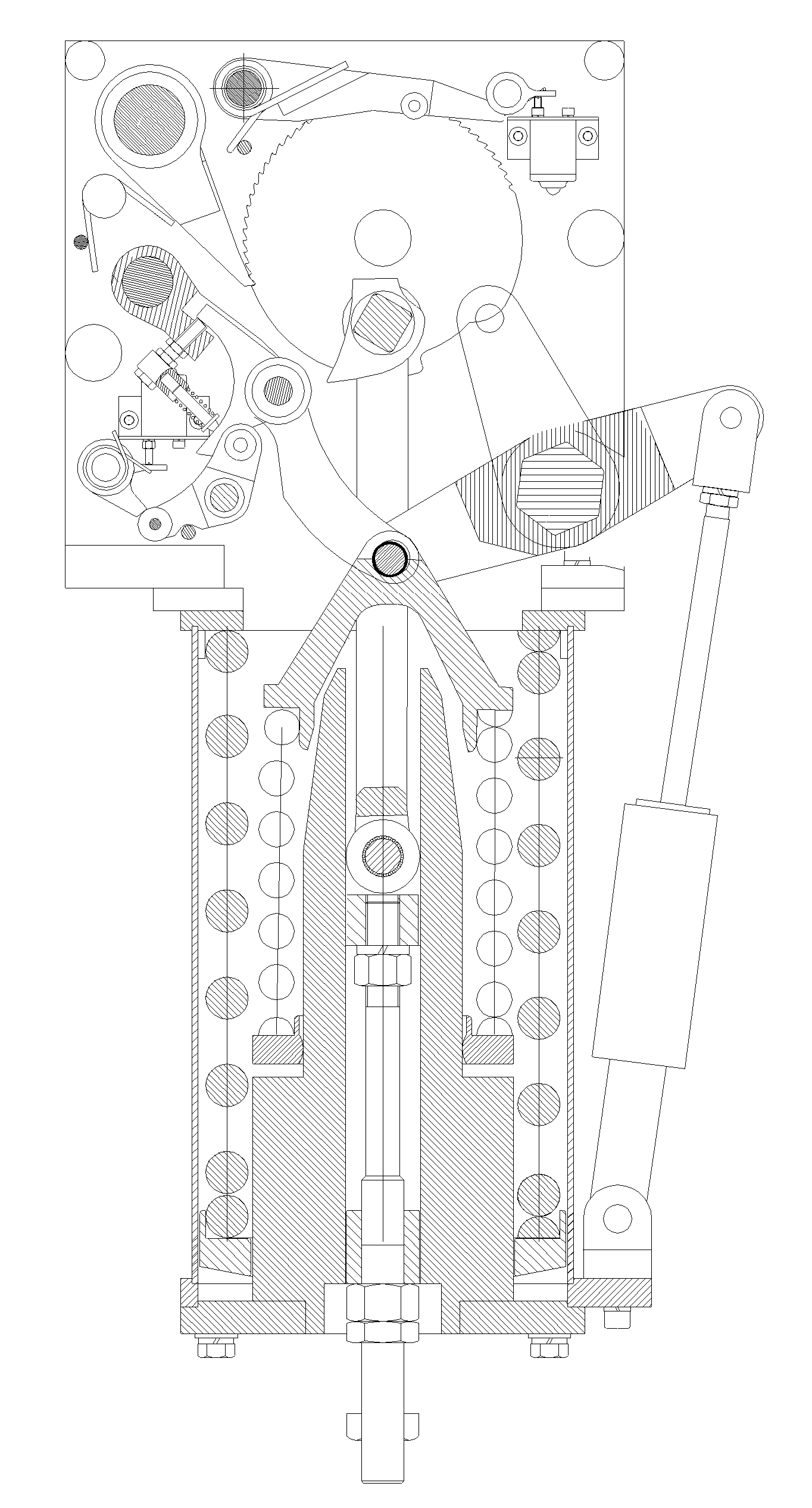

[0018] The accompanying drawings of the present invention are numbered as follows: 1. Positioning column, 2. Closing detent, 3. Closing detent arm, 4. Closing electromagnet, 5. Closing roller, 6. Closing reset torsion spring , 7, ratchet, 8, output crank arm, 9, cam, 10, positioning detent, 11, output shaft, 12, transmission crank arm, 13, buffer piston rod, 14, spring seat, 15, buffer cylinder, 16, Fixed seat, 17, wall plate, 18, crankshaft, 19, ratchet, 20, ball head ejector rod, 21, small turning arm, 22, spring, 23, opening electromagnet, 24, roller before opening, 25, Opening detent arm, 26, opening reset torsion spring, 27, opening detent A, 28, opening detent B, 29, opening rear roller, 30, connecting plate, 31, connecting rod, 32 , closing spring, 33, opening spring, 34, guide seat, 35, spring barrel, 36, guide roller, 37, joint, 38, guide pad, 39, screw rod, 40, supporting plate, 41, pawl reset Torsion spring, 42, adapter, 43, bridge connecting plate, 44, closing res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com