Lithium secondary battery bank

A technology for lithium secondary batteries and battery packs, applied in lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of uneven current density distribution, battery capacity attenuation, poor cycle performance, etc., and achieve good battery safety performance and consistency. Improve and improve the effect of battery heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Such as Figure 4 As shown, in a 345.6V, 40Ah lithium iron phosphate battery pack for a hybrid electric vehicle, 108 3.2V, 10Ah lithium iron phosphate single cells 101 are connected in series to form a 345.6V, 10Ah lithium iron phosphate battery pack unit 102, and then Four 345.6V, 10Ah lithium iron phosphate battery pack units 102 are connected in parallel to form a 345.6V, 40Ah lithium iron phosphate battery pack 103 .

[0051] Since the charging and discharging rate of the hybrid electric vehicle battery pack is quite large, this embodiment and the conventional combination form 1, that is, four 3.2V, 10Ah lithium iron phosphate single cells are connected in parallel to form a 3.2V, 40Ah lithium iron phosphate The battery is connected in series by 108 3.2V, 40Ah lithium iron phosphate batteries to form a 345.6V, 40Ah lithium iron phosphate battery pack. Compared with this, the phenomenon of uneven current density distribution between single batteries will be effective...

Embodiment 2

[0053] Such as Figure 5As shown, in the 48V, 300Ah nickel-cobalt-manganese ternary material lithium secondary battery pack with a charging and discharging current of 100A for communication backup power supply, there are 15 3.6V, 10Ah nickel-cobalt-manganese ternary materials with a maximum charging and discharging current of 5 times The single battery 201 of the element material is connected in parallel to form a 3.6V, 150Ah nickel-cobalt-manganese ternary material lithium secondary battery 202, and then 13 3.6V, 150Ah nickel-cobalt-manganese ternary material lithium secondary batteries 202 are connected in series to form a 48V, 150Ah battery. The nickel-cobalt-manganese ternary material lithium secondary battery unit 203, and then two 48V, 150Ah nickel-cobalt-manganese ternary material lithium secondary battery units 203 are connected in parallel to form a 48V, 300Ah nickel-cobalt-manganese ternary material lithium secondary battery pack 204.

[0054] The present embodiment...

Embodiment 3

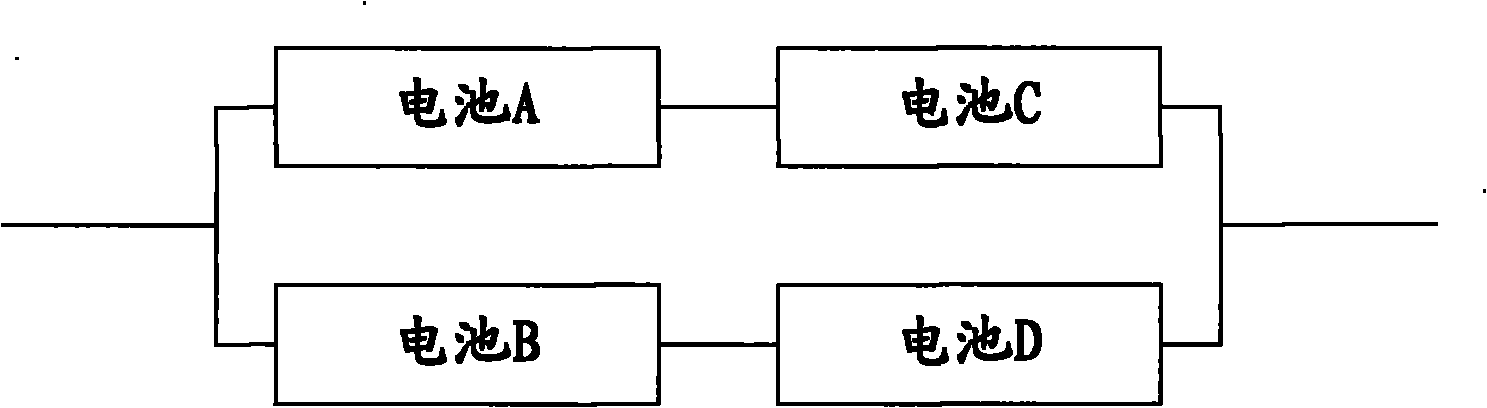

[0057] Such as Figure 6 , Figure 7 As shown, in a 288V, 100Ah lithium manganate battery pack for pure electric vehicles, two 3.7V, 12.5Ah lithium manganate cells 301 are connected in parallel to form a 3.7V, 25Ah lithium manganate battery 302, and then 13 3.7 V, 25Ah lithium manganate batteries 302 are connected in series to form a 48V, 25Ah lithium manganate battery pack unit 303, and then four 48V, 25Ah lithium manganate battery pack units 303 are connected in parallel to form a 48V, 100Ah lithium manganate battery pack module 304 , and then six 48V, 100Ah lithium manganate battery pack modules 304 are connected in series to form a 288V, 100Ah lithium manganate battery pack 305 .

[0058] This embodiment and the conventional combination form one, that is, eight 3.7V, 12.5Ah lithium manganate cells are connected in parallel to form a 3.7V, 100Ah lithium manganate battery, and then seventy-eight 3.7V, 100Ah lithium manganate batteries are The batteries are connected in ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com