Carbon dioxide hardened sodium silicate sand swage sand shooting modeling method

A water glass sand and carbon dioxide technology, applied in the field of casting molding, can solve problems such as poor production quality, complicated process, and environmental pollution, and achieve the effects of improving strength, avoiding rough surfaces, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

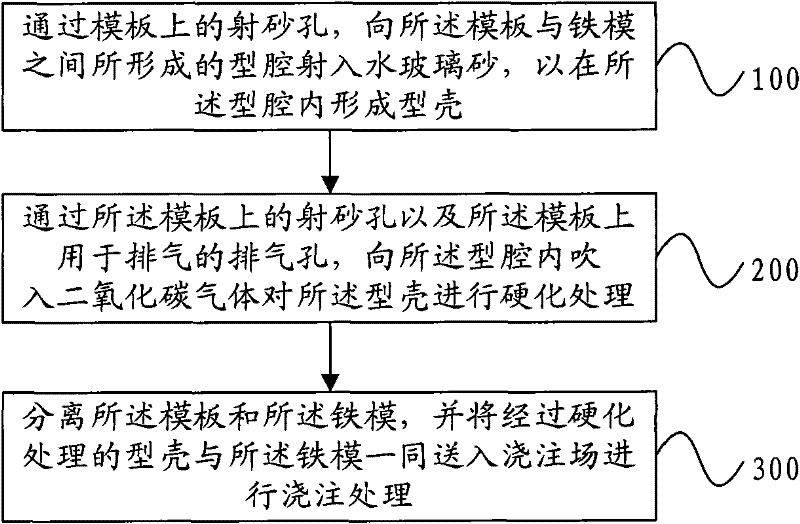

[0014] figure 1 It is a flow chart of an embodiment of the carbon dioxide hardened sodium silicate sand iron mold injection sand molding method of the present invention. Such as figure 1 As shown, the method includes:

[0015] Step 100, injecting water glass sand into the cavity formed between the template and the iron mold through the sand shooting holes on the template to form a shell in the cavity;

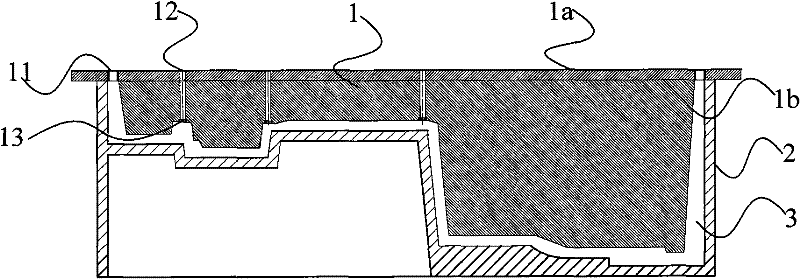

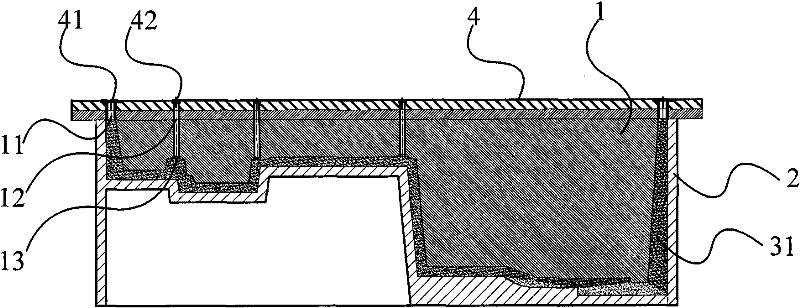

[0016] The formwork includes two parts, the bottom plate and the pattern. The inside of the iron form has a shape corresponding to the form. When the formwork and the iron form are combined, a "gap" corresponding to the form is formed between the two. The "gap" is the cavity used to form the shell. The template is provided with a sand shooting hole, through which the water glass sand is injected into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com