Method for refining telmisartan

A technology for telmisartan and a purification method, applied in the field of chemistry, can solve the problems of cumbersome process, long process route and the like, and achieve the effects of simple process route, good product quality and good product color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

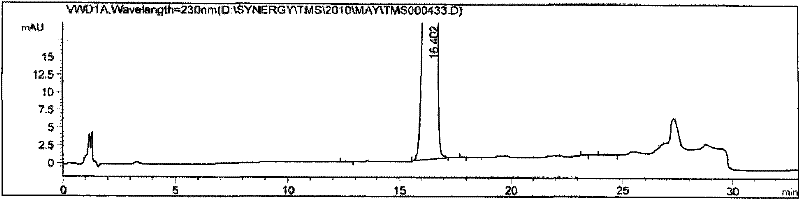

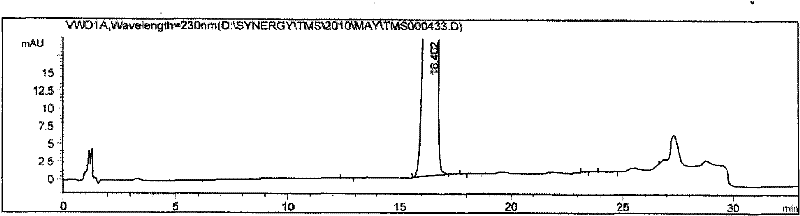

Image

Examples

Embodiment 1

[0034] 1) prepare the crude product of telmisartan potassium salt

[0035] Put 500ml of isopropanol, 65g of telmisartan (0.126mol, content 98%), and 8.0g of potassium hydroxide (0.143mol) into a 1000ml four-necked bottle and stir, heat up to 75-80°C to dissolve, add 6.5g of activated carbon, And decolorize at this temperature for 1 hour, filter, the filtrate is cooled to 0° C. to crystallize for 8 hours, filter, and dry the filter cake under reduced pressure at 60° C. for 8 hours to obtain 62 g of crude telmisartan potassium salt.

[0036] 2) Refined Telmisartan Potassium Salt

[0037] Put 240ml of isopropanol into a 500ml four-necked bottle, 120% of ethyl acetate, 62g of crude telmisartan potassium salt, dissolve at 75-80°C, add 5g of activated carbon to decolorize for 1 hour, filter, and cool the filtrate to 0°C to crystallize for 8 hours. After filtering, the filter cake was dried under reduced pressure at 60° C. for 8 hours to obtain 58 g of refined telmisartan potassium ...

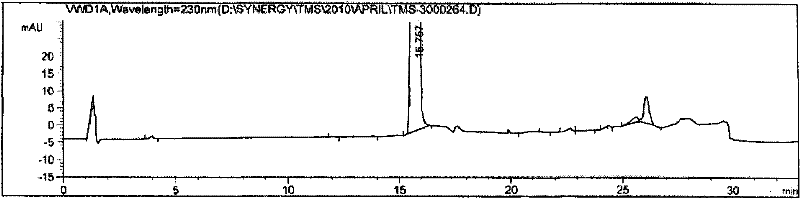

Embodiment 2

[0041] 1) prepare the crude product of telmisartan potassium salt

[0042] Put 500ml of isopropanol, 65g of telmisartan (0.126mol, content 98%), and 8.0g of potassium hydroxide (0.143mol) into a 1000ml four-necked bottle and stir, heat up to 75-80°C to dissolve, add 6.5g of activated carbon, And decolorize at this temperature for 1 hour, filter, the filtrate is cooled to 0° C. to crystallize for 8 hours, filter, and the filter cake is dried under reduced pressure at 60° C. for 8 hours to obtain 66 g of crude telmisartan potassium salt.

[0043] 2) Refined Telmisartan Potassium Salt

[0044] Put 350ml of isopropanol and 66g of crude telmisartan potassium salt into a 500ml four-necked bottle, heat up to 75-80°C to dissolve, add 5g of activated carbon to decolorize for 1 hour, filter, cool the filtrate to 0°C to crystallize for 8 hours, filter, filter cake Dry under reduced pressure at 60°C for 8 hours to obtain 62g of refined telmisartan potassium salt

[0045] 3) hydrolysis o...

Embodiment 3

[0048] 1) prepare the crude product of telmisartan potassium salt

[0049] Into the 1000ml four-necked bottle, 500ml of isopropanol, 65g of telmisartan (0.126mol, content 98%), and 60ml of 23.7% potassium carbonate water solution (0.143mol) were successively put into the bottle and stirred, heated to 75-80°C to dissolve, and added 6.5 g activated carbon, and decolorized at this temperature for 1 hour, filtered, and the filtrate was cooled to 0° C. to crystallize for 8 hours, filtered, and the filter cake was dried under reduced pressure at 60° C. for 8 hours to obtain 56 g of crude product of telmisartan potassium salt.

[0050] 2) Refined Telmisartan Potassium Salt

[0051] Put 350ml of isopropanol and 56g of crude telmisartan potassium salt into a 500ml four-necked bottle, dissolve at 75-80°C, add 5g of activated carbon to decolorize for 1 hour, filter, cool the filtrate to 0°C to crystallize for 8 hours, filter, filter cake Dry under reduced pressure at 60°C for 8 hours to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com