Construction method of steel sheet pile cofferdam for integral type steel purlin

A technology of steel sheet pile cofferdam and construction method, which is applied in basic structure engineering, construction, etc., can solve the problems of difficult quality assurance, difficult construction, long period, etc., achieve obvious energy saving effect, reduce construction difficulty, and reduce permanent construction. effect of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

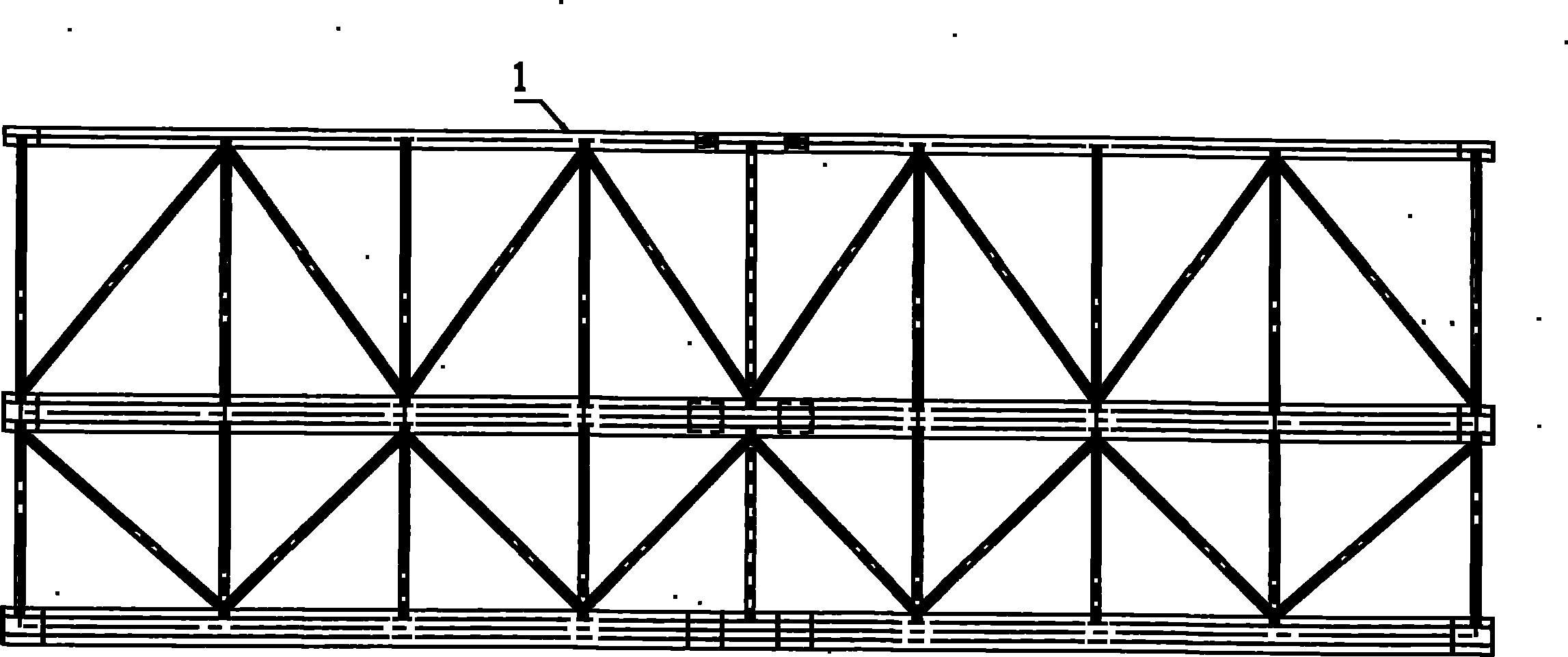

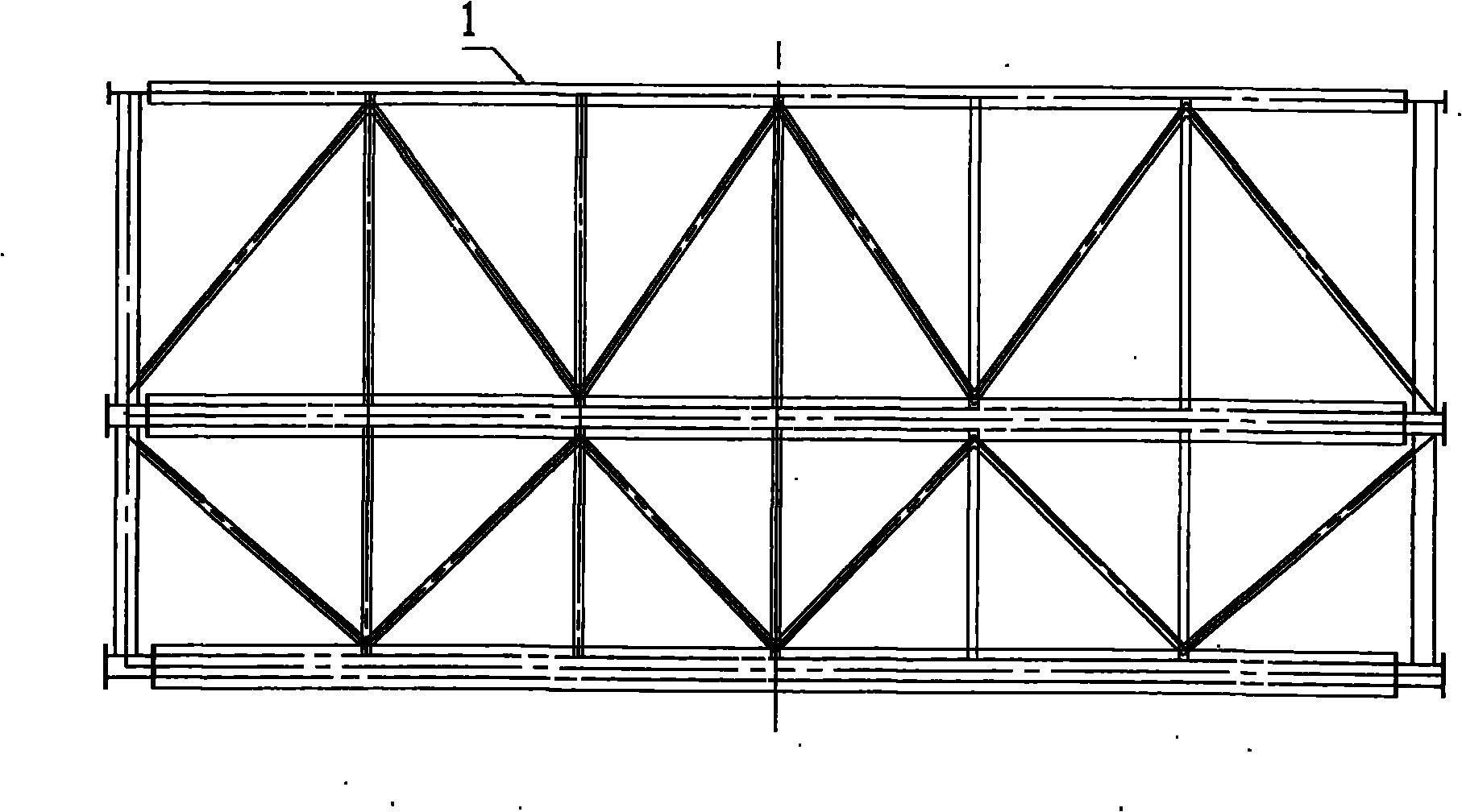

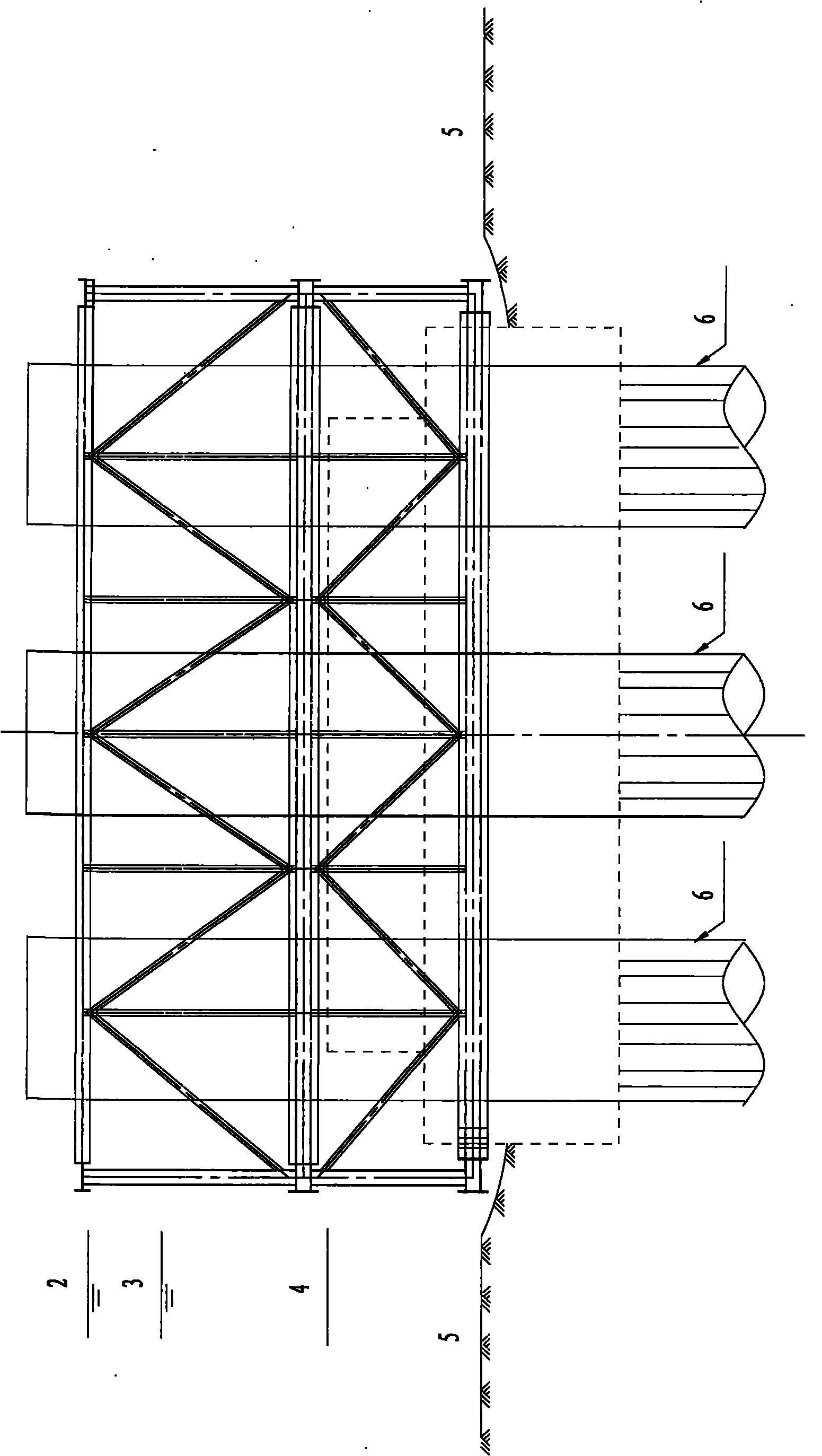

[0034] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0035] The construction method of integral steel purlin steel sheet pile cofferdam, the specific steps are as follows:

[0036] Step 1: 1. Fabricate steel purlins on land as a whole.

[0037] Step 2: 1. Use a grab bucket and a suction dredger to clear the riverbed below the steel purlins. 2. Use a floating crane to lower the steel purlins as a whole. 3. The steel purlins are consolidated on the four corner pile casings.

[0038] Step 3: 1. Using steel purlins as guides, insert and drive steel sheet pile cofferdams around the site. 2. Under the condition that the internal and external water heads are consistent, suck up mud and clean the river bed to the bottom of the back-sealing concrete. 3. Construction of back-sealing concrete.

[0039] Step 4: 1. Pump water from the foundation pit, remove the steel casing and break the pile head, 2. Set up a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com