Method for manufacturing optical fiber positioning groove of substrate used for optical fiber communication by mould pressing process

An optical fiber positioning and positioning groove technology, which is applied in the coupling of optical waveguides and other directions to achieve the effects of low cost, fast production speed and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] With reference to the accompanying drawings, this embodiment takes the positioning groove as a V-shaped groove as an example.

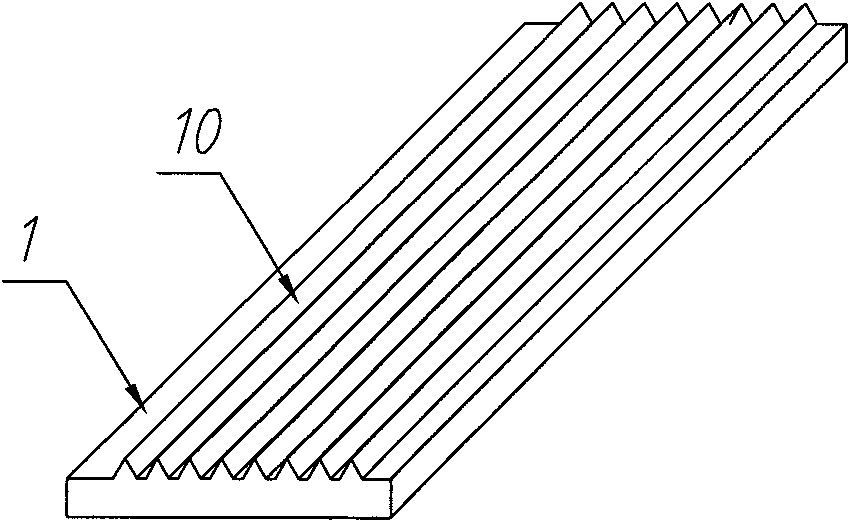

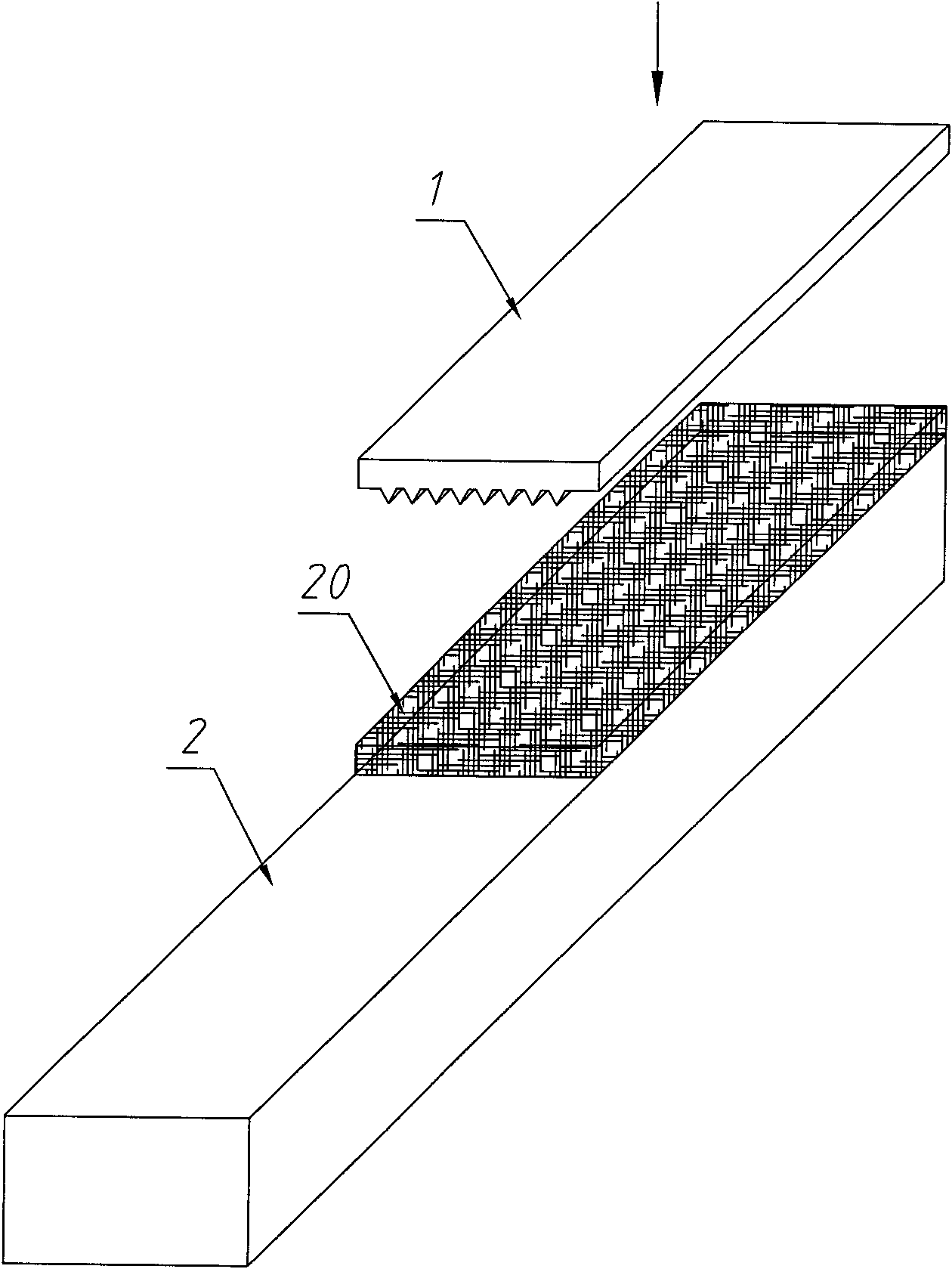

[0020] refer to figure 2 , 5 , the method provides a template 1, and one side surface of the template is provided with a positioning groove mold 10 having the same groove shape as the V-groove.

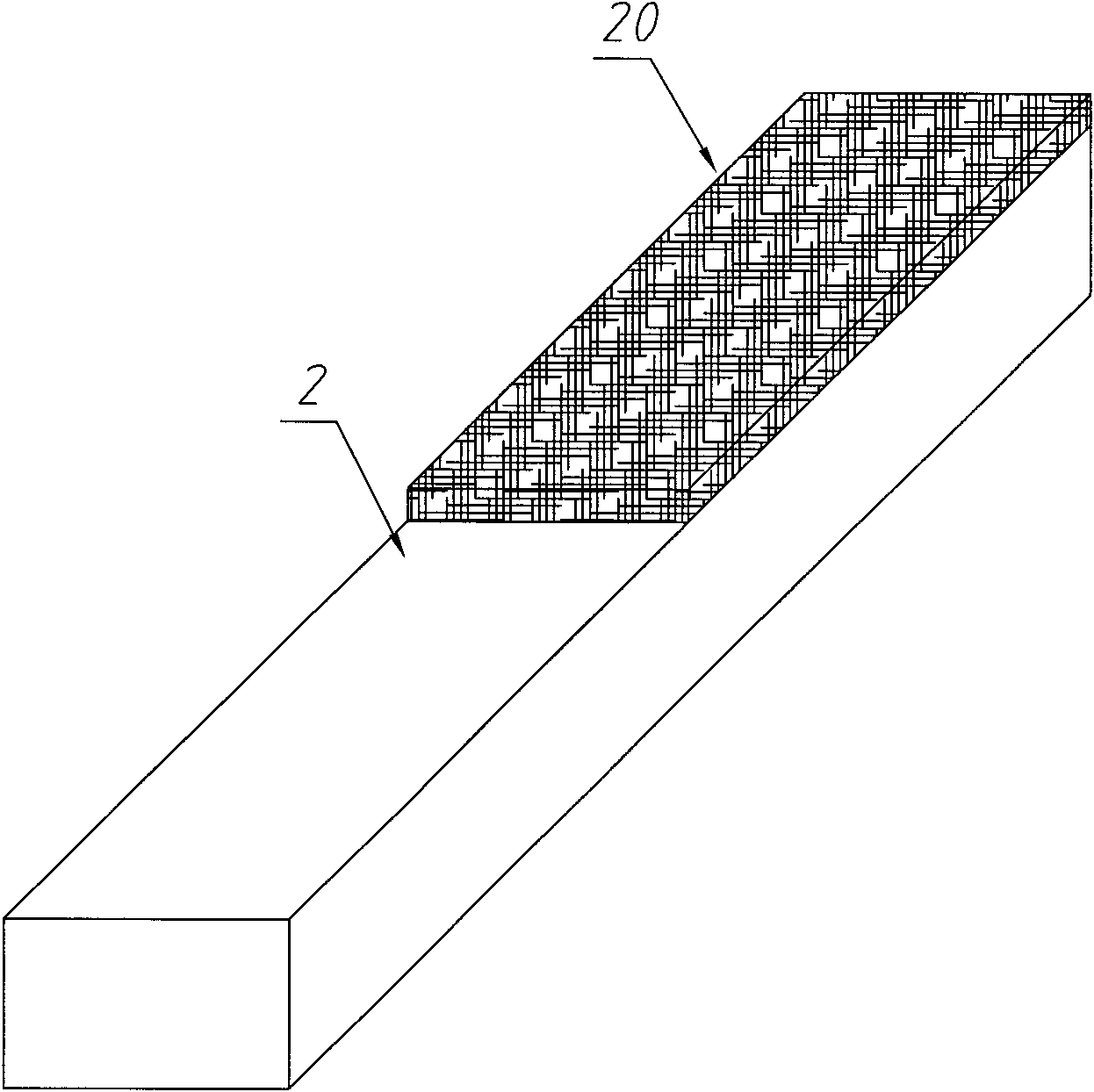

[0021] refer to figure 1 , the method includes the step of uniformly coating a layer of film 20 on the surface of the substrate 2, the thickness of the film layer is greater than the groove depth of the positioning groove.

[0022] The method also includes the step of coating a layer of release agent on the surface of the positioning slot mold of the template,

[0023] The method also includes the steps of:

[0024] refer to image 3 , 4 , press the side of the template coated with one layer of release agent with the positioning groove mold in the direction of the arrow on the substrate coated with the film layer to form a positioning groove 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com