Gas insulating transformer

A gas insulation and transformer technology, applied in the field of transformers and transformers, can solve the problems of high noise of oil-immersed transformers, large area occupied by substations, and oil pollution of the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

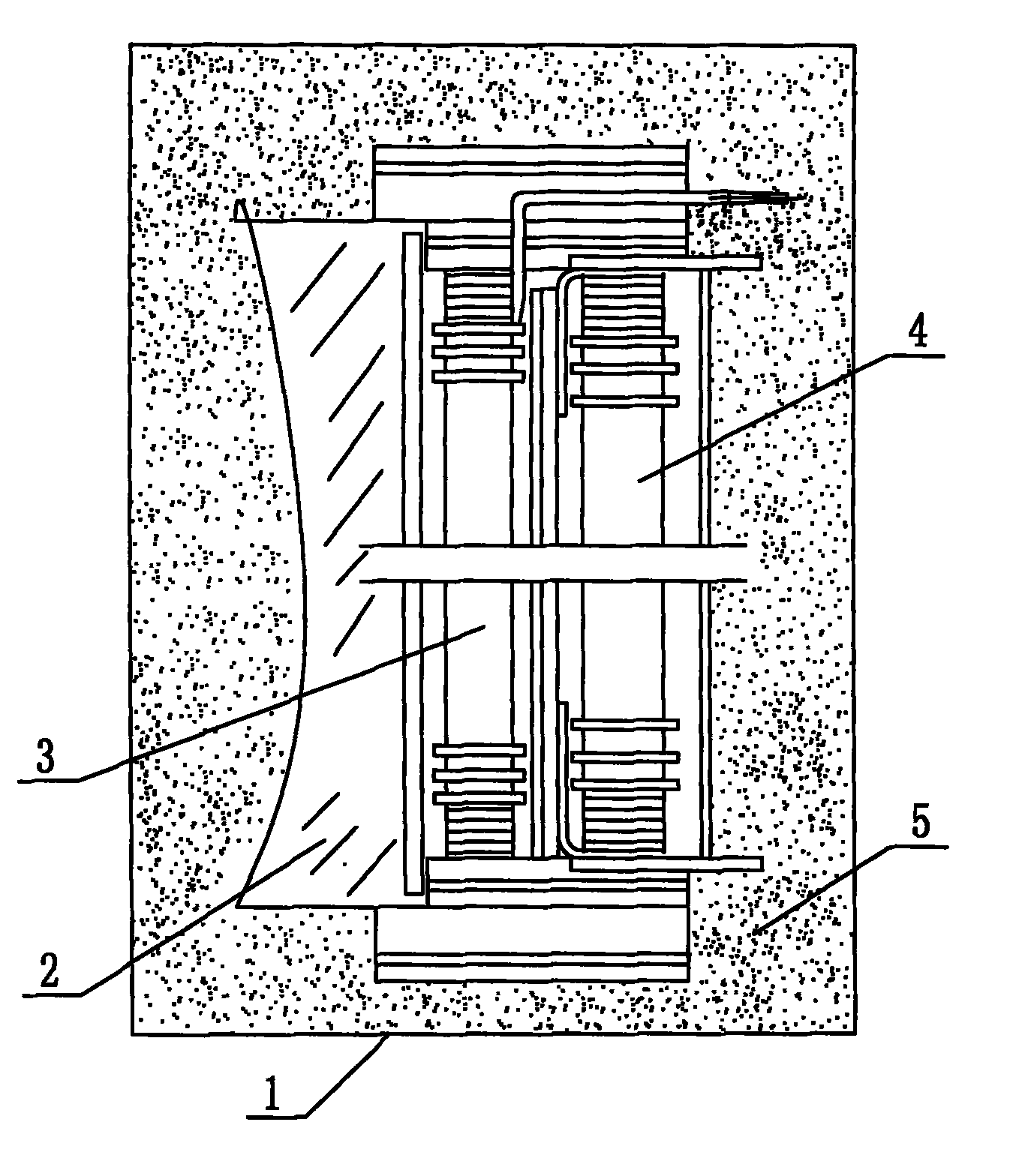

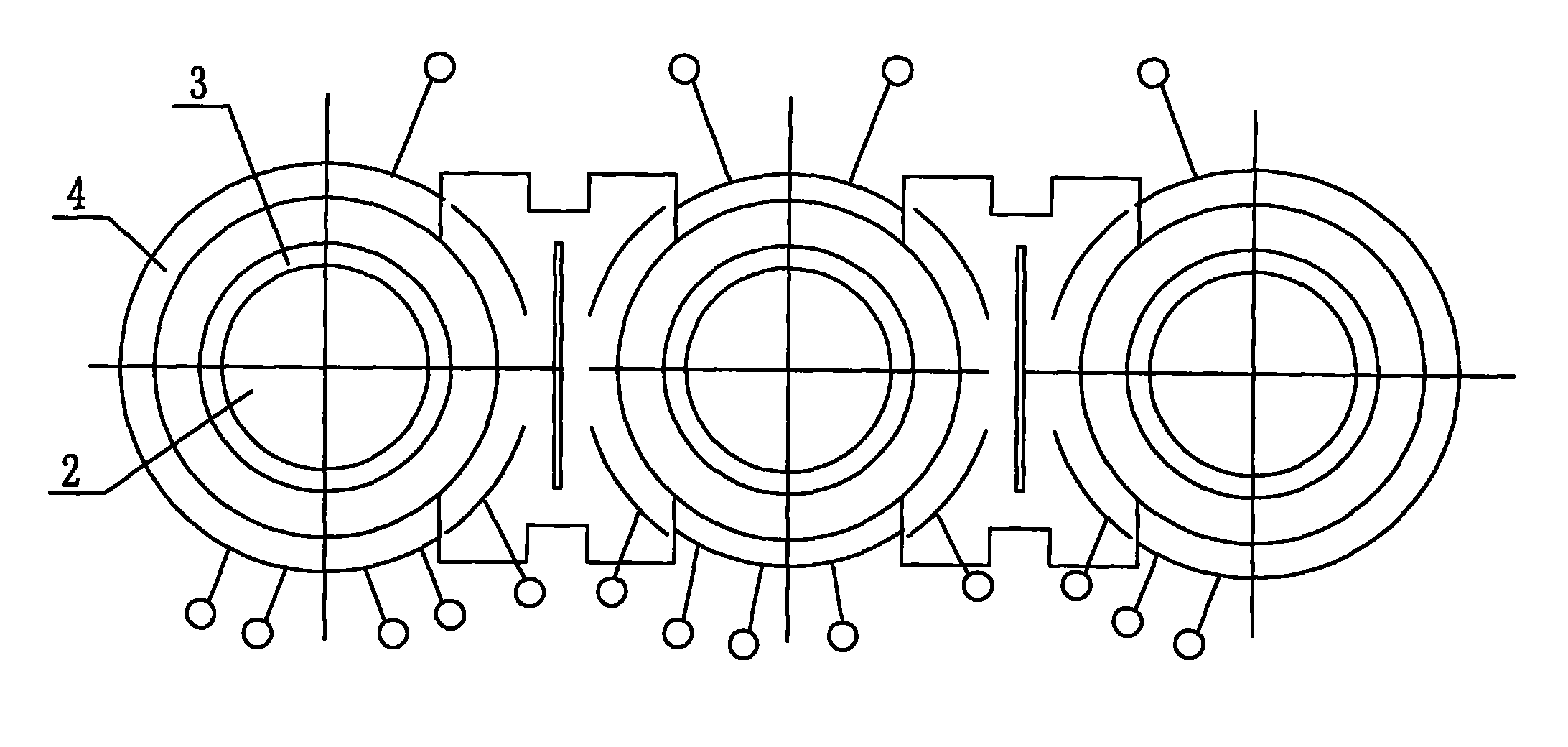

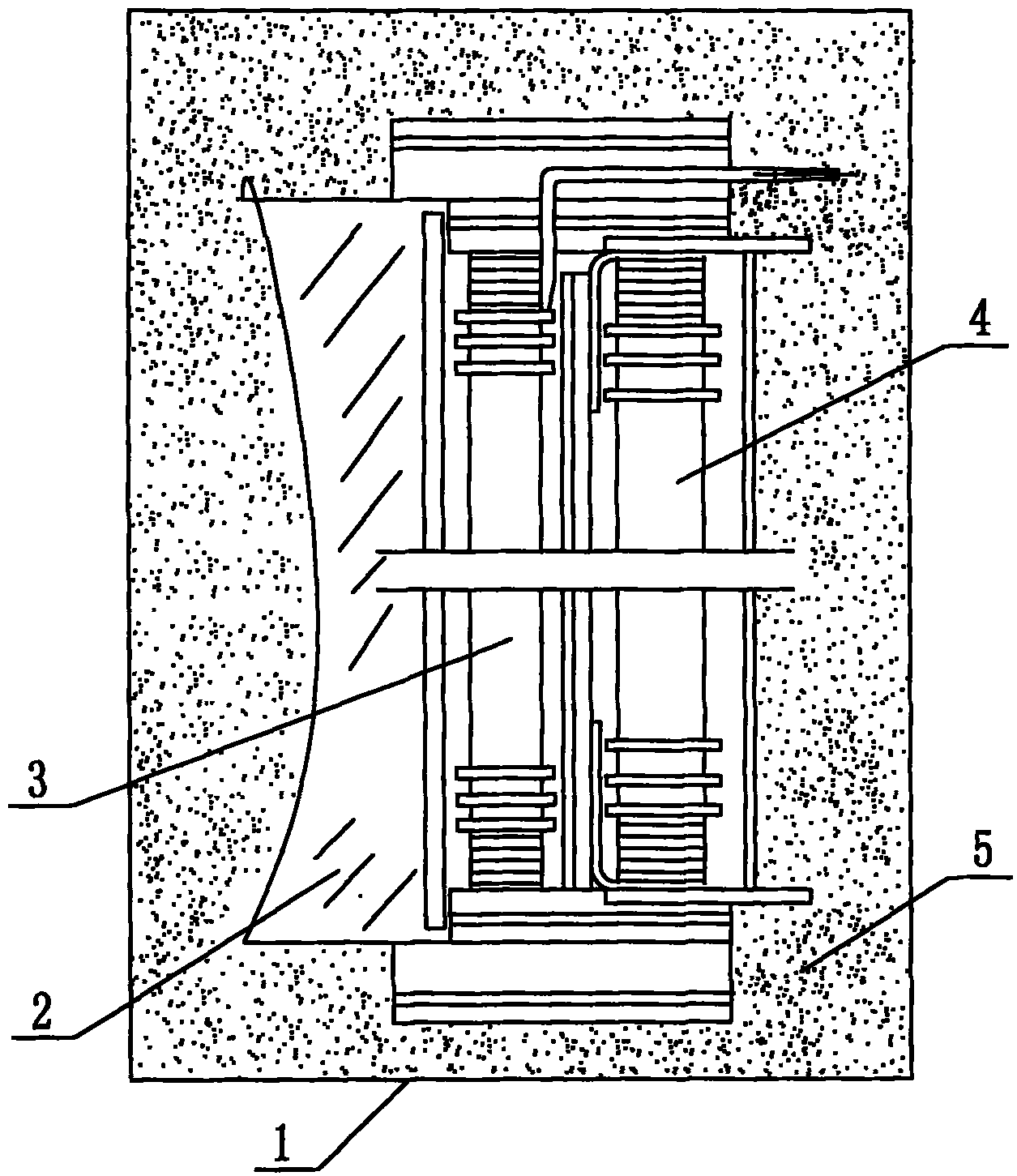

[0012] Such as figure 1 , 2 As shown, a gas-insulated transformer is composed of a gas box 1 and an iron core 2 located in the gas box 1, a low-voltage winding 3, a high-voltage winding 4, and an insulating medium. Both the low-voltage winding 3 and the high-voltage winding 4 are set on the iron core 2, and The high-voltage winding 4 is located outside the low-voltage winding 3, and the high-voltage winding 4 and the low-voltage winding 3 are separated by an insulating material, the insulating material is cardboard, and the insulating medium is pure gaseous SF6 gas 5.

[0013] The high-voltage winding 4 adopts a tangled-continuous structure. According to the impulse voltage distribution of the wave process computer, the insulation thickness of the turns of the winding and the size of the air passage between the cakes are adjusted to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com