Low output loss LLC resonant converter

A resonant converter, low-output technology, applied in output power conversion devices, DC power input conversion to DC power output, instruments, etc., can solve the limitation of resonant converter efficiency improvement, large ripple current RMS, rectifier diodes The problem of large loss, etc., can solve the effect of large output capacitor ripple, smaller ripple, and reduced volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

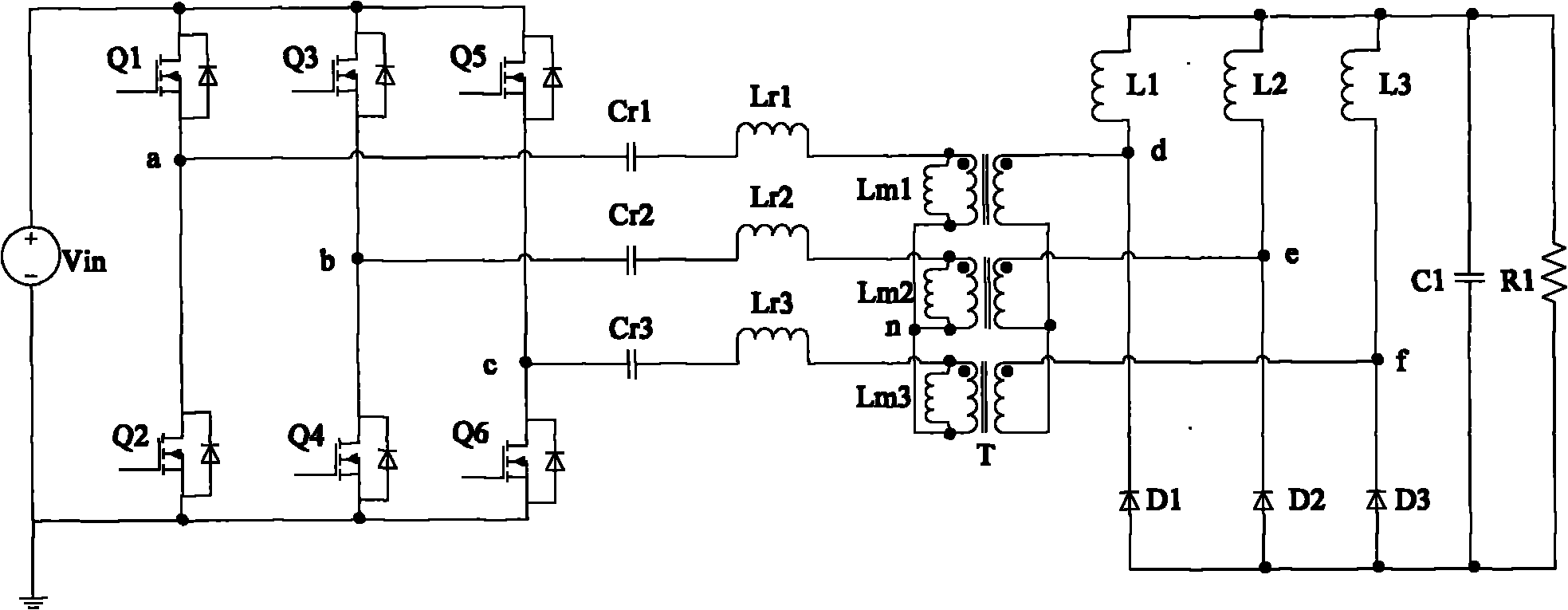

[0035] Such as figure 1 The three-leg LLC resonant converter shown is a typical three-leg LLC resonant converter, including an inverter, a resonant circuit, a three-phase transformer T, a rectifier circuit, and a filter circuit. The three-phase transformer T is connected in a Y~Y shape.

[0036] The inverter on the primary side of the three-phase transformer T consists of three bridge arms connected in parallel to invert the DC voltage into a square wave or ladder wave voltage. The lag angle between each bridge arm is 120°, that is, the second bridge arm composed of switching tubes Q3 and Q4 lags behind the first bridge arm composed of switching tubes Q1 and Q2 by 120°, and is composed of switching tubes Q5 and Q6 The third bridge arm lags behind the second bridge arm formed by switching tubes Q3 and Q4 by 120°, and the first bridge arm formed by switching tubes Q1 and Q2 lags behind the third bridge arm formed by switching tubes Q5 and Q6 120°. The driving signals of the ...

specific Embodiment approach 2

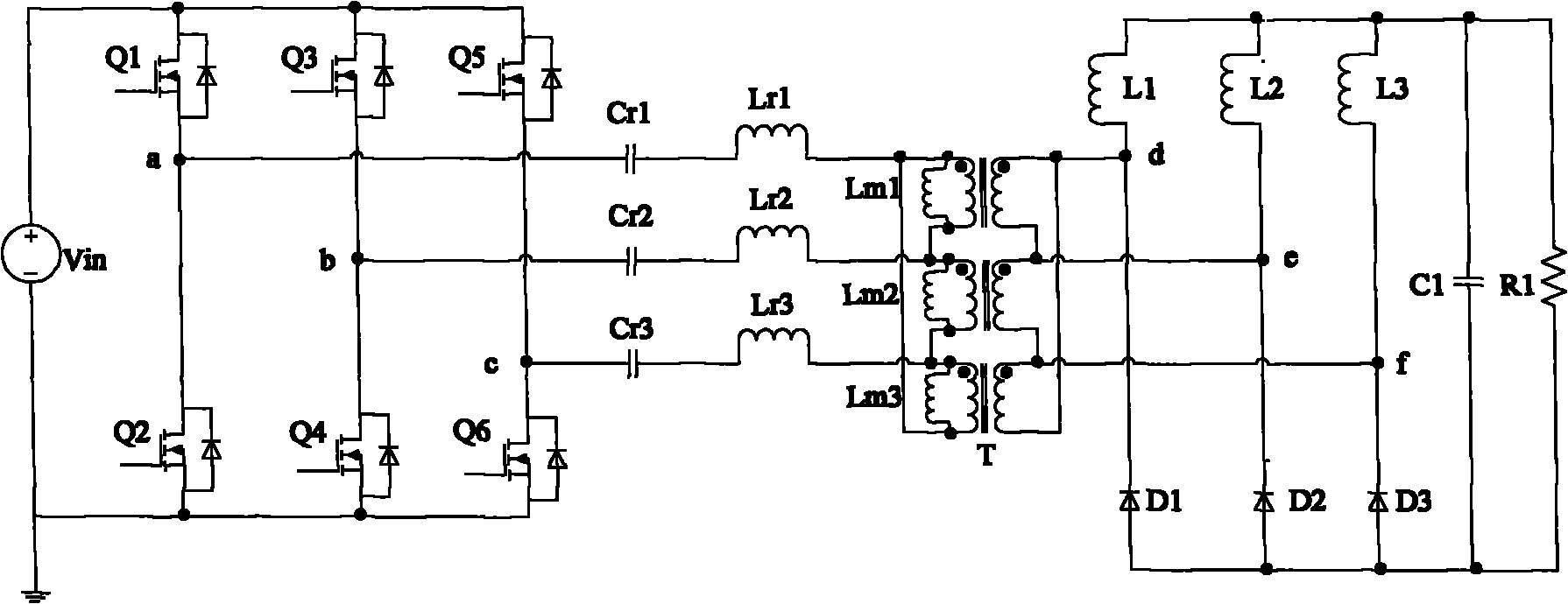

[0063] Such as figure 2 The three-leg LLC resonant converter shown is a modified three-leg LLC resonant converter, which also includes an inverter, a resonant circuit, a three-phase transformer T, a three-phase rectifier circuit, and a filter circuit. The difference from Embodiment 1 is that: the three-phase transformer T is connected in a Δ-Δ shape.

[0064] The second embodiment has basically the same beneficial effects as the first embodiment.

specific Embodiment approach 3

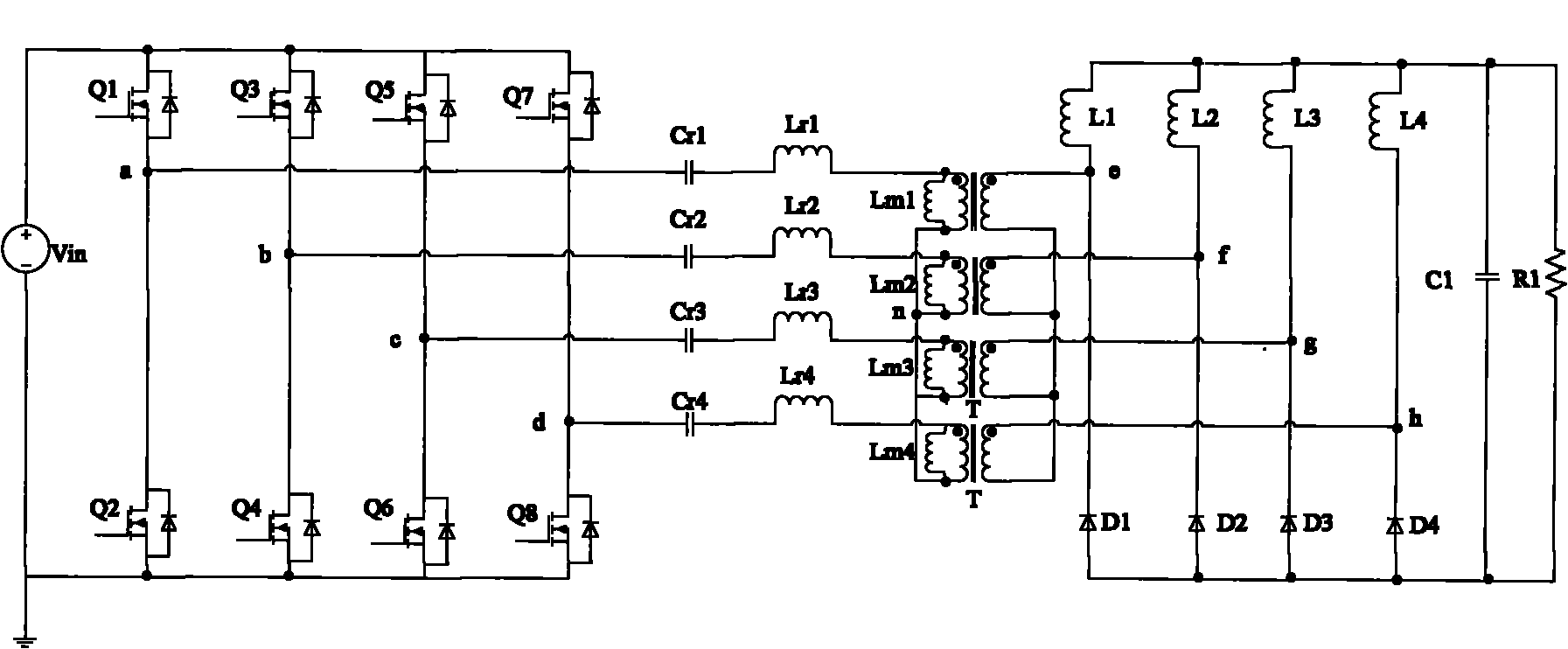

[0065]Such as image 3 The four-leg LLC resonant converter shown is a modified LLC resonant converter, including an inverter, a resonant circuit, a four-phase transformer, a four-phase rectifier circuit, and a filter circuit. One of the differences from Embodiment 1 is that the inverter on the primary side of the four-phase transformer T is composed of four bridge arms connected in parallel, and the lag angle between each bridge arm is changed from 120° of the three bridge arms to 90°. That is, the second bridge arm formed by switching tubes Q3 and Q4 lags behind the first bridge arm formed by switching tubes Q1 and Q2 by 90°, and the third bridge arm formed by switching tubes Q5 and Q6 lags behind the first bridge arm formed by switching tubes Q3 and Q6. The second bridge arm formed by Q4 is 90°, the fourth bridge arm formed by switch tubes Q7 and Q8 lags behind the third bridge arm formed by switch tubes Q5 and Q6 by 90°, and the fourth bridge arm formed by switch tubes Q1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com