Forced circulating reboiler

A technology of forced circulation and reboiler, which is applied in the direction of boiling devices, chemical instruments and methods, etc., can solve the problems of affecting the distribution effect of falling film reboilers, reducing efficiency, affecting liquid film formation, etc., so as to overcome the problems of heat preservation and leakage , reduce the operating temperature, reduce the effect of liquid height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

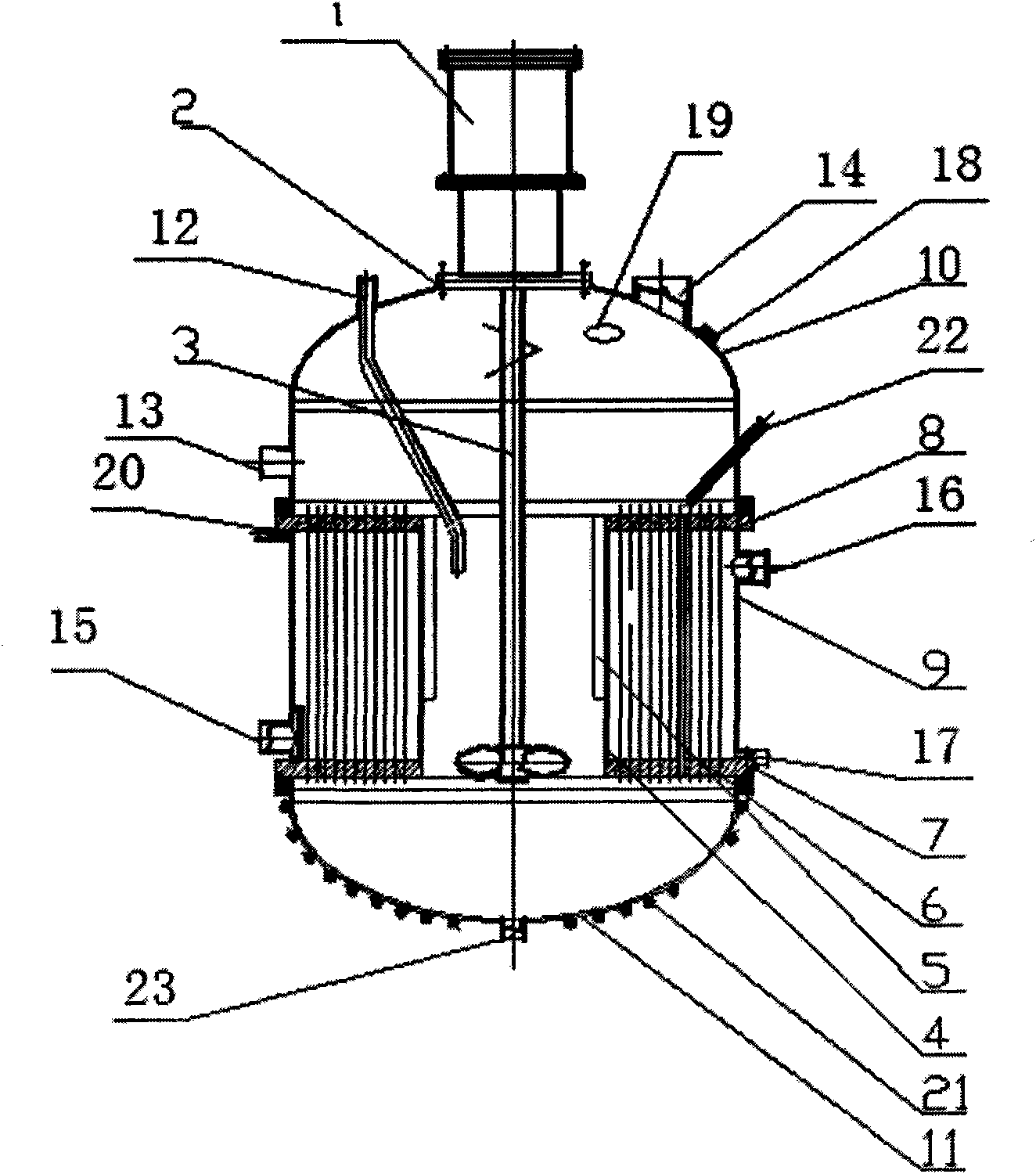

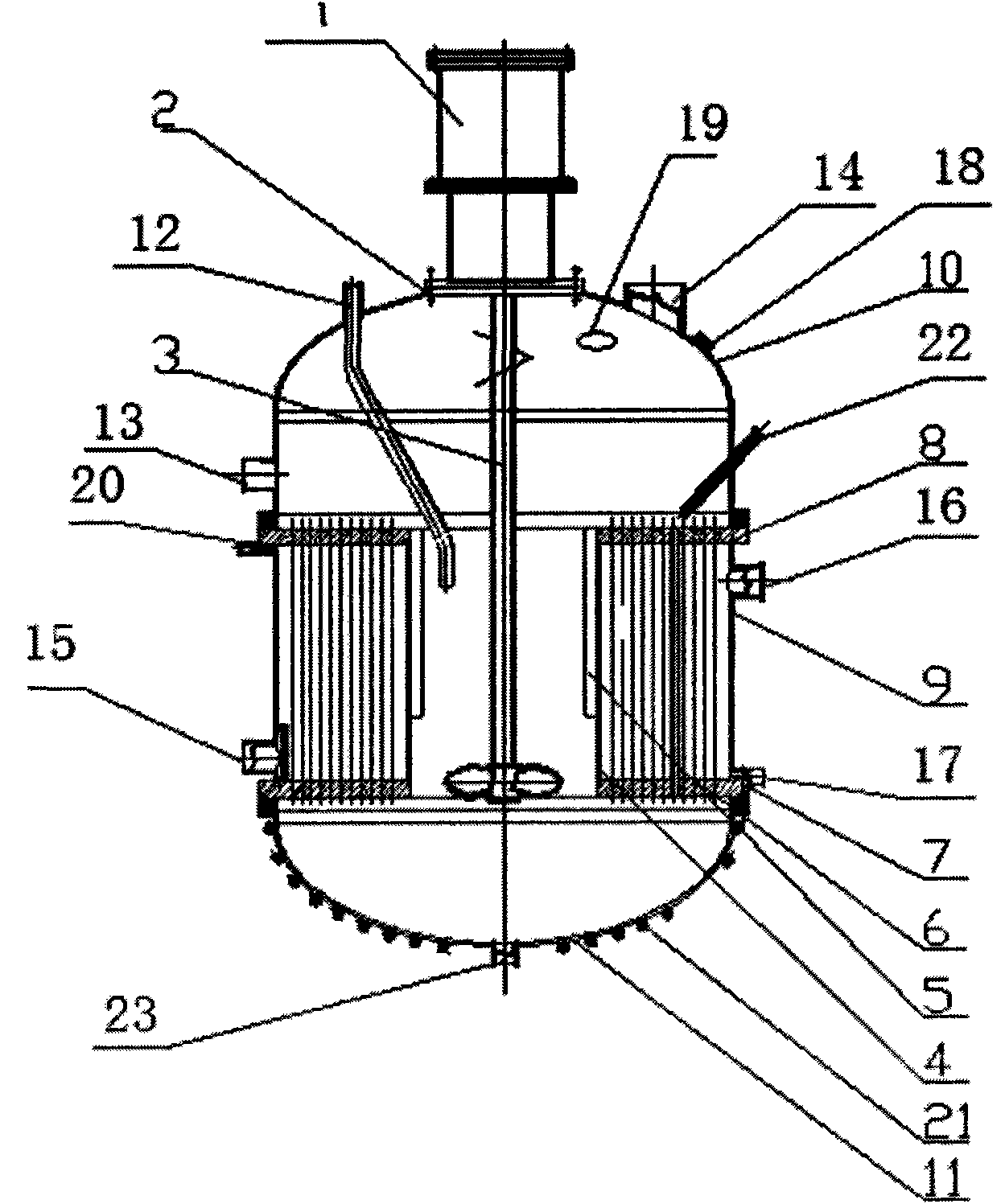

[0028] Such as figure 1 As shown, the upper and lower heads 10 and 11 are respectively connected to the top and bottom of the cylinder 9 to form the reboiler body, and the upper annular plate 8 and the lower annular plate 7 are respectively connected to the inner wall of the cylinder 9, and the upper annular plate 8 and the central ring hole of the lower annular plate 7 are connected to the tube plate to form a guide tube 4, and the heat exchange tube 6 is connected between the ring plate of the upper annular plate 8 and the lower annular plate 7, and a pusher type is installed in the guide tube 4. Stirring device 3, the stirring impeller of the push-type stirring device 3 is located at the lower part of the guide tube 4, the push-type stirring device 3 is connected to the stirring transmission device 1 located outside the reboiler body, and the stirring transmission device 1 is installed on the reboiler through the flange 2 On the body, a liquid outlet 13 is provided on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com