Paint exhaust treatment device

A waste gas treatment device and paint technology, which is applied in the direction of smoke removal, dispersion particle separation, chemical instruments and methods, etc., can solve the problems affecting the health of employees and environmental pollution, and achieve the effect of protecting health and reducing environmental pollution

Inactive Publication Date: 2010-09-29

安徽宏宇玻璃有限公司

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the production process of glass silver mirrors, it is necessary to coat the silver-plated and copper-plated mirrors with a paint protective layer first, so that the silver-plated and copper-plated layers of the lens can be durable; the paint contains important pollutants such as benzene, and its exhaust gas is directly discharged to the workshop and the atmosphere will cause serious environmental pollution, and long-term discharge will directly affect the health of employees

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

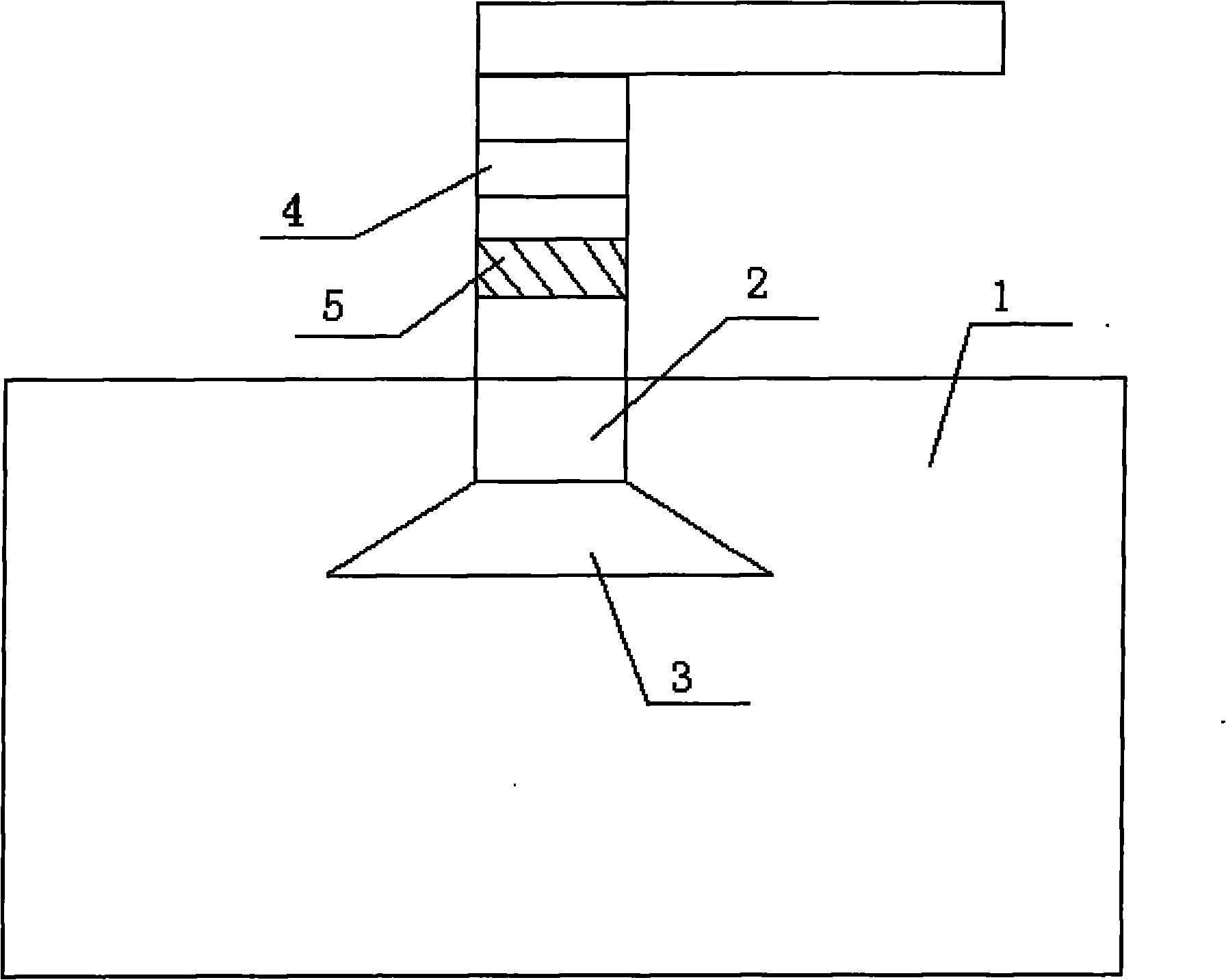

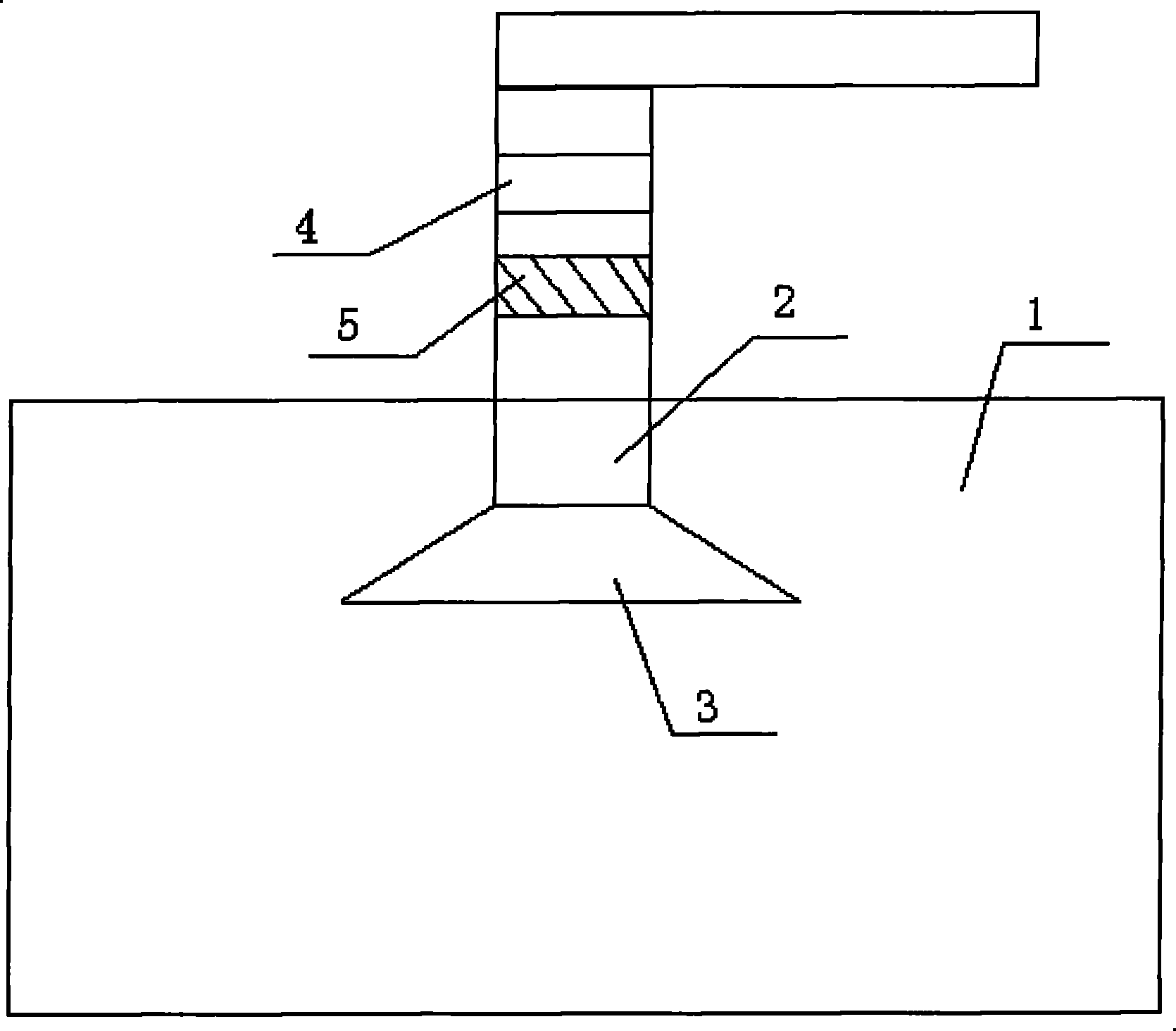

[0009] Paint exhaust gas treatment device, including closed workshop 1: there is an exhaust port on the top of closed workshop 1, and an exhaust pipe 2 is installed in the exhaust port. Exhaust fan 4 is arranged, and activated carbon filtering device 5 is installed in the middle part of exhaust pipe 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a paint exhaust treatment device, which comprises a closed workshop, wherein the top end of the closed shop is provided with an exhaust opening; an exhaust air duct is arranged in the exhaust opening; a trumpet-shaped suction opening is arranged at the lower end of the exhaust air duct; an exhaust fan is arranged at the inner upper end of the exhaust air duct; and an activated carbon filtering device is arranged on a middle part in the exhaust air duct. In the paint exhaust treatment device, the painting workshop is closed, and paint exhaust is deodorized with the overhead exhaust air duct, is absorbed and filtered with activated carbon and then is exhausted overhead, so environmental pollution can be greatly reduced, the benzene content and aldehyde content of the exhaust produced by the painting process workshop on an eyeglass production line are completely consistent with national related stipulation, and the healthy of workers is well protected.

Description

Technical field: [0001] The invention relates to the field of glass production equipment, in particular to a paint waste gas treatment device. Background technique: [0002] In the production process of glass silver mirrors, it is necessary to coat the silver-plated and copper-plated mirrors with a paint protective layer first, so that the silver-plated and copper-plated layers of the lens can be durable; the paint contains important pollutants such as benzene, and its exhaust gas is directly discharged to the workshop It will cause serious environmental pollution in the environment and the atmosphere, and long-term discharge will directly affect the health of employees. Invention content: [0003] In order to solve the problems existing in the existing technology, a paint waste gas treatment device is specially provided. By closing the paint workshop, using high-altitude exhaust pipes to deodorize the paint waste gas and using activated carbon to absorb and filter the was...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/02B01D46/30B08B15/00

Inventor 陶玲玲

Owner 安徽宏宇玻璃有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com