Novel high-accuracy jewelry processing equipment

A processing equipment, high-precision technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of reducing the processing accuracy and production efficiency of parts, time-consuming and laborious operation, and low jewelry processing accuracy. The effect of improving production efficiency, convenient and quick operation and use, improving the pass rate and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

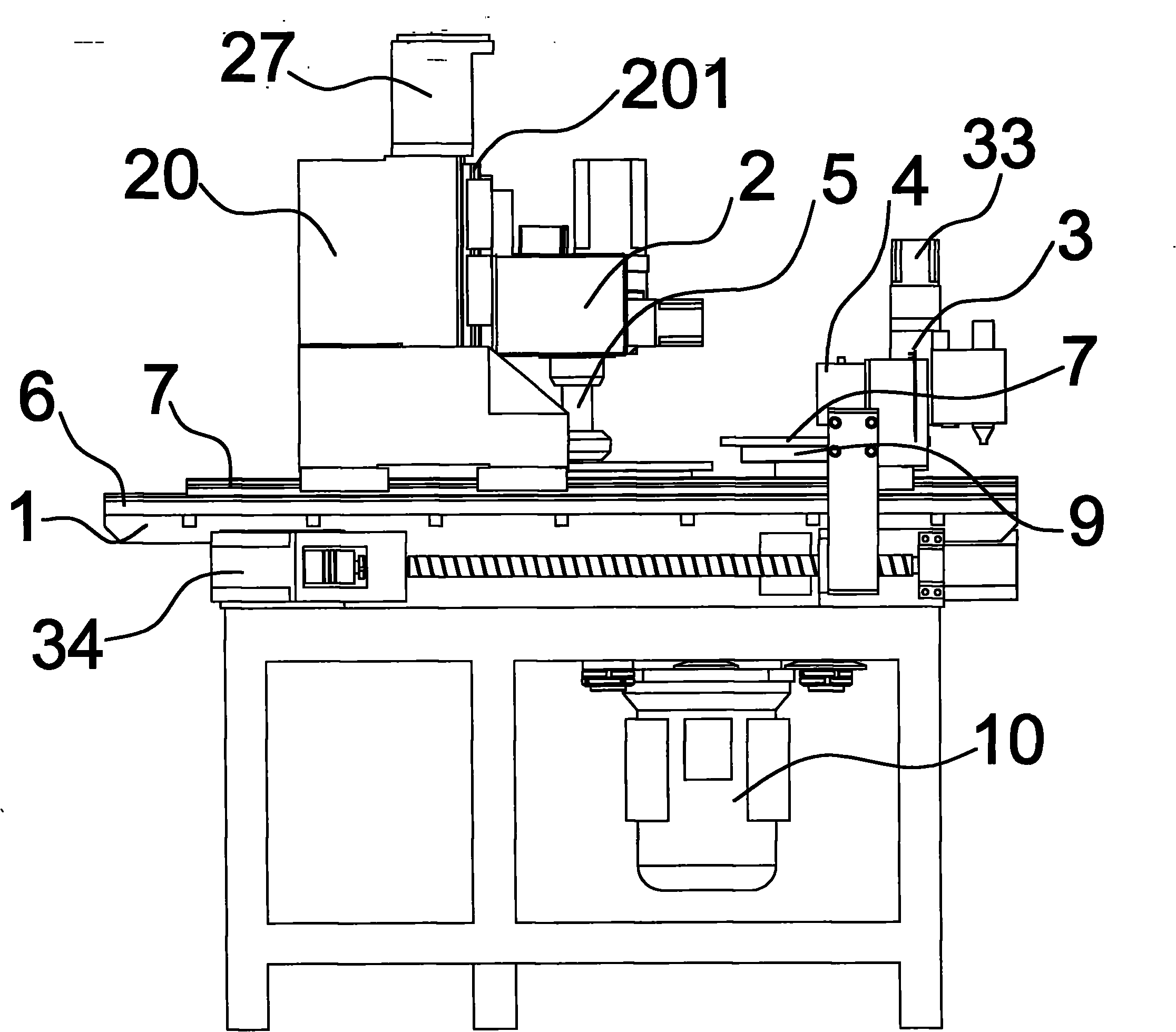

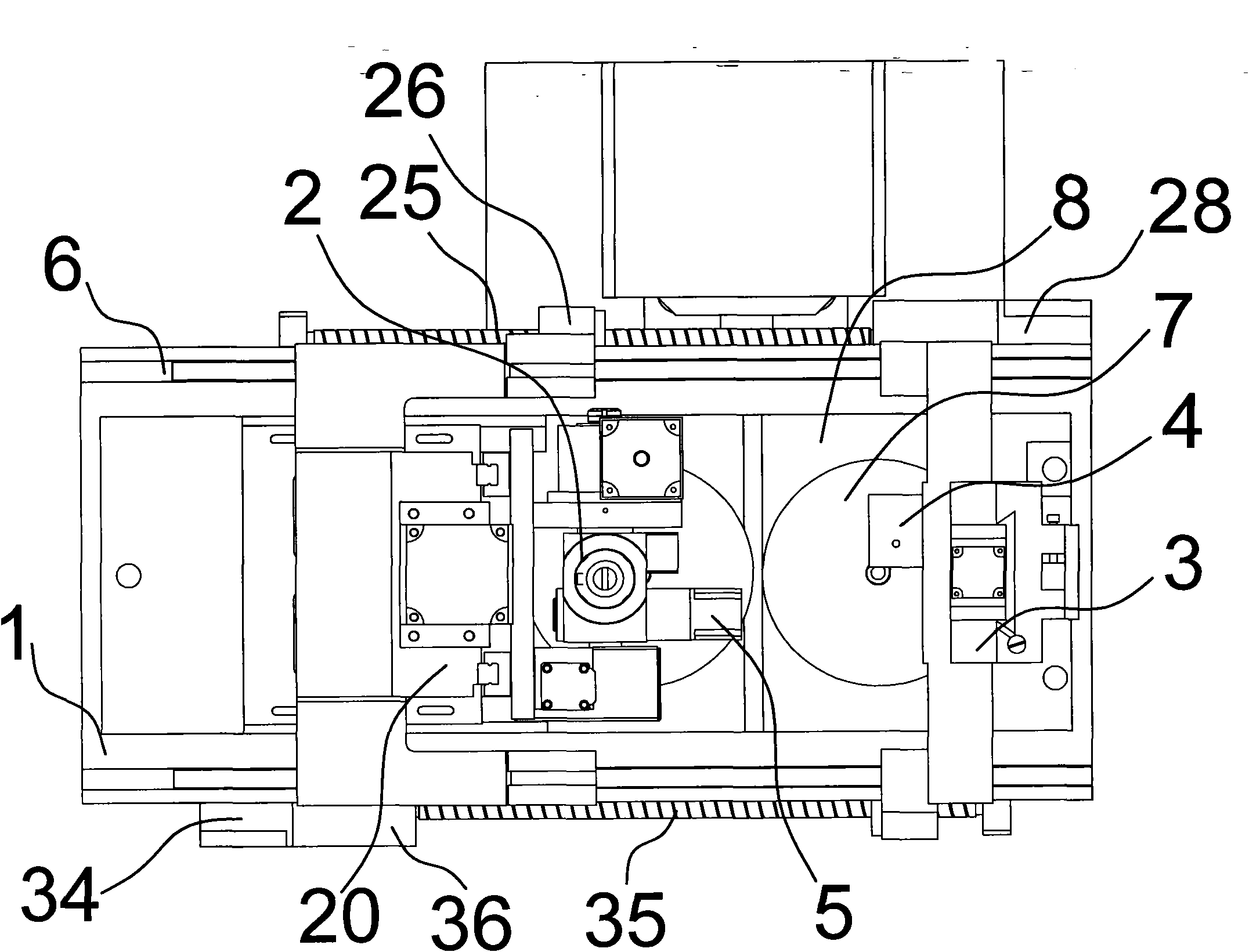

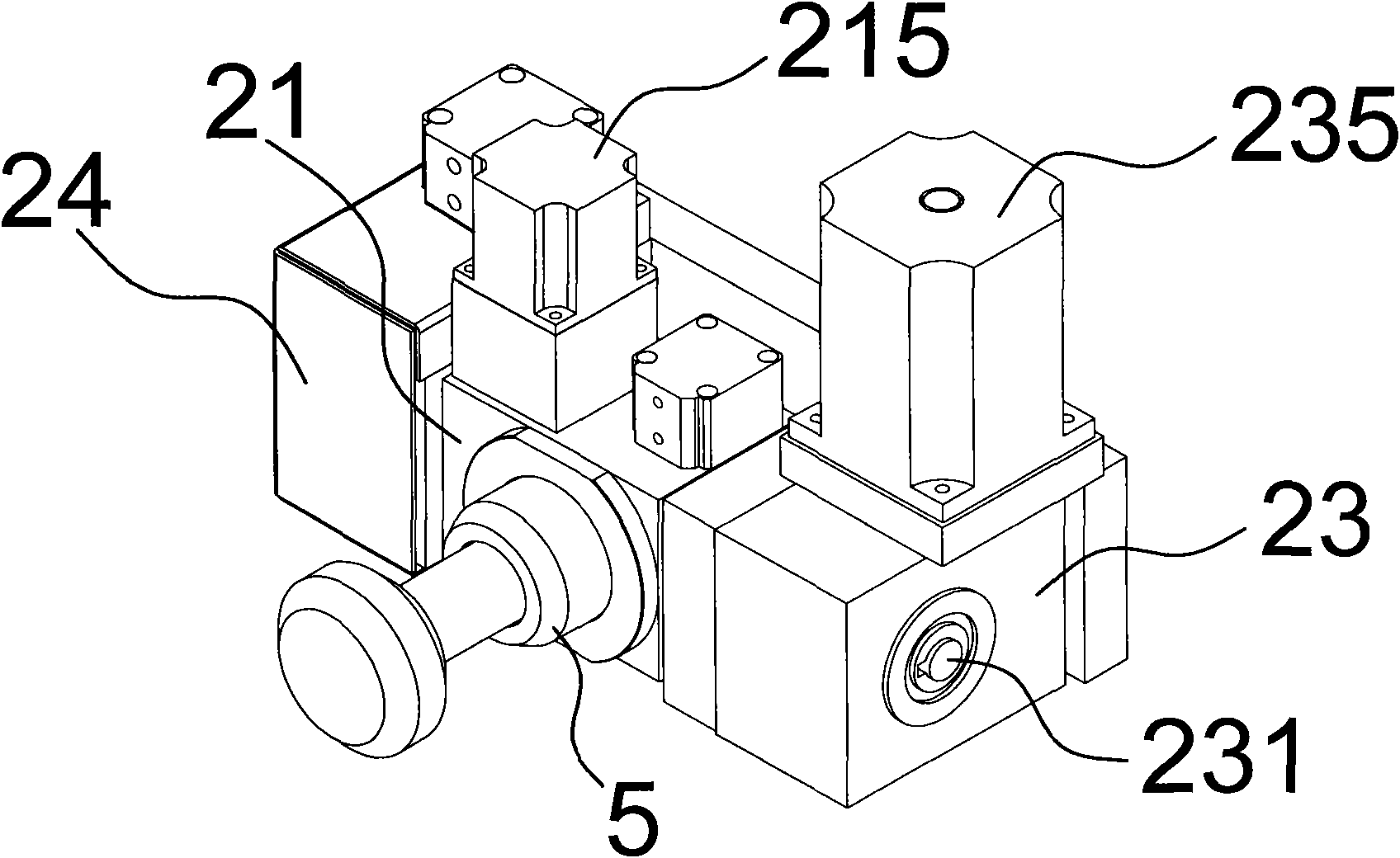

[0025] Such asfigure 1 and figure 2 As shown, a new type of high-precision jewelry processing equipment of the present invention includes a processing platform 1 with two adjacent water tanks 8 on the processing platform 1, and two grinding machines with different heights are horizontally fixed in the water tank 8. Disc base 9, grinding discs 7 with different hardness are respectively fixed above the grinding disc base 9, the grinding disc base 9 with a low position is fixed with a hard disk for grinding, and the grinding disc base 9 with a high position is fixed The soft disk for polishing is connected to the two grinding disk seats 9 respectively through the rotating shaft and the grinding disk rotating motor 10 on the side of the processing platform 1. On the processing platform 1 on both sides of the water tank 8, there are two parallel fixed disks along the horizontal direction. A horizontal slide rail 6, across two horizontal slide rails 6, a grinding head device and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com