High performance concrete with water quenching manganese slag and preparation method thereof

A high-performance concrete, water-quenched manganese slag technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc. General application of performance concrete and other issues to achieve high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

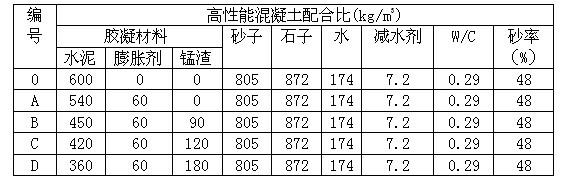

Embodiment 1

[0078] Embodiment 1: take by weighing 18kg (6%) natural anhydrite (SO 3 content 50%) mixed with 282kg water-quenched manganese slag, and the water-quenched manganese slag mixed with natural anhydrite is ground until the specific surface area is ≥ 420m 2 / kg, and then mixed with 100kg of expansion agent (concrete admixture that meets the requirements of the national standard for concrete expansion agent GB23439-2009) and 600kg of cement (in line with GB175 "General Portland Cement" 42.5 grade) to obtain a hydraulic cementitious material; take water 600kg of hard cementitious material, add crushed stone (conforming to the standard requirements of GB / T14685-2001 "pebbles and gravel for construction", the maximum particle size is 3cm), 1032kg of sand (conforming to the standard of GB / T14684-2001 "Sand for Construction" artificial sand Quality requirements) 688kg (sand rate 40%), water 180kg (water-cement ratio 30%) and surfactant (in line with JG / T223-2007 "polycarboxyla...

Embodiment 2

[0079] Embodiment 2: take by weighing 20kg (8%) natural anhydrite (SO 3 content > 45%) mixed with 230kg of water-quenched manganese slag, and the water-quenched manganese slag mixed with natural anhydrite is ground until the specific surface area is ≥ 420m 2 / kg, and then mixed with 90kg of expansion agent (in line with the national standard for concrete expansion agent GB23439-2009) and 660kg of cement (in line with GB175 "General Portland Cement" 42.5 grade) to obtain a hydraulic cementitious material; take hydraulic cementitious material 580kg, add crushed stone (maximum particle size 3 ). After testing, its slump is 21cm, and its 28-day strength is 74MPa.

Embodiment 3

[0080] Example 3: Weigh 10.5kg (7%) of natural anhydrite and mix it into 139.5kg of water-quenched manganese slag, and grind together until the specific surface area is ≥ 420m 2 / kg, then mixed with 80kg of expansion agent and 770kg of cement to obtain hydraulic cementitious material; take 550kg of hydraulic cementitious material, add crushed stone 1430kg, sand 477kg (sand rate 25%), water 143kg (water-cement ratio 26%) and 6.6kg of surfactant, mix and stir evenly to obtain water-quenched manganese slag high-performance concrete (with a bulk density of 2600kg / m 3 )。

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com