Production method for lowering contents of sulfur and alkene in gasoline

A production method and technology for olefin content, which are applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve problems such as difficulty in meeting clean gasoline, make up for the loss of octane number, reduce olefin content, and ensure octane number. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

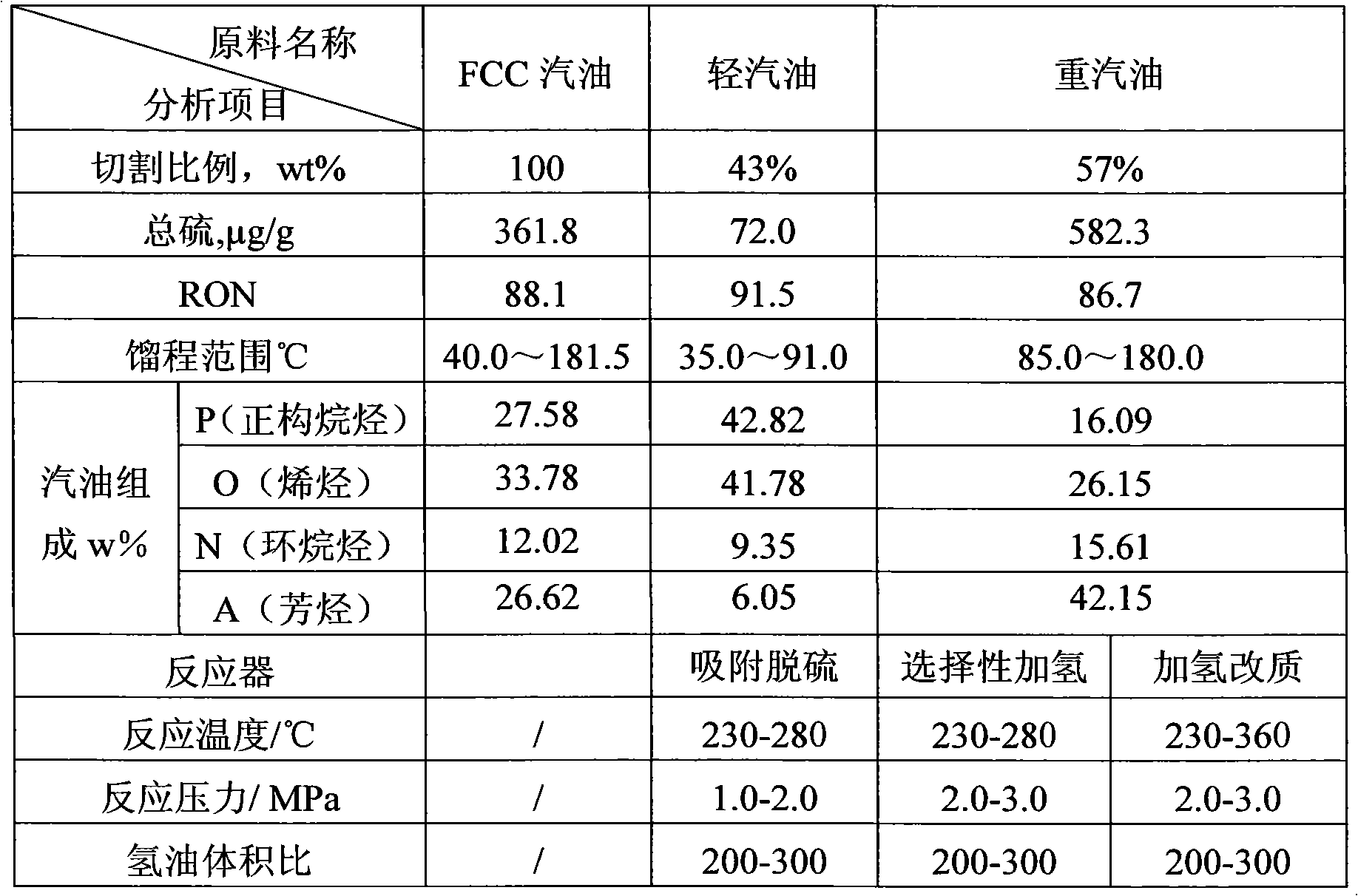

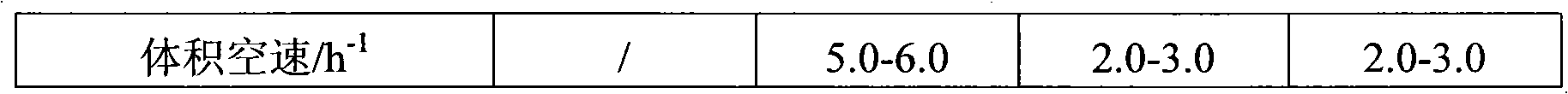

Embodiment 1

[0025] After the whole cut FCC gasoline enters the pre-hydrogenation reactor to remove diolefins, it enters the fractionation tower for cutting and fractionation, light gasoline is adsorbed and desulfurized, and heavy gasoline is subjected to selective hydrodesulfurization and then hydrogenated and upgraded. Among them, the selective hydrogenation catalyst used in the prehydrogenation reactor is an industrial agent; the light gasoline adsorption desulfurization reactor chooses a fixed bed reactor, and the adsorption desulfurization agent used is an industrial agent; the selective hydrogenation catalyst used in the heavy gasoline selective hydrodesulfurization reactor The hydrodesulfurization catalyst is an industrial agent; the hydromodification agent used in the hydromodification reactor is an industrial agent. The reaction results are shown in Table 2.

[0026] The data in Table 2 shows that after adsorption and desulfurization of light gasoline, the sulfur content dropped f...

Embodiment 2

[0030] The raw materials, catalysts and reaction process conditions used are the same as in Example 1, the difference is that the hydrogenation upgrading reactor is omitted, heavy gasoline is directly blended with light gasoline adsorption desulfurization product after selective hydrodesulfurization, light gasoline product and heavy gasoline product After reconciliation, the sulfur content is 18.6μg / g, meeting the requirements of Euro IV sulfur index, but the octane number is lost by 2.3 units, and the total liquid yield is 99.9%. The specific reaction results are shown in Table 3.

[0031] Table 3 Example 2 data

[0032]

Embodiment 3

[0034] The raw materials, catalyst and reaction process conditions used are the same as those in Example 1, except that the light gasoline is desulfurized by the traditional alkali-elution desulfurization method. After the light gasoline is desulfurized by alkali, the sulfur content is reduced from 72.0 μg / g to 50.2 μg / g. g. The desulfurization effect is obviously inferior to that of the adsorption desulfurization method. After the light gasoline alkali washing desulfurization product is reconciled with the heavy gasoline product, the sulfur content is 29.5 μg / g, which meets the requirements of the Euro IV sulfur index. The specific reaction results are shown in Table 4.

[0035] Table 4 Example 3 data

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com