Full-range FCC gasoline combined desulfurization process and device

A desulfurization process and full-fraction technology, applied in the petroleum industry, hydrotreating process, hydrocarbon oil treatment, etc., can solve the problems of large octane number loss, frequent adsorbent regeneration, long hydrodesulfurization process route, etc. Low investment and operating costs, high adsorption selectivity and adsorption capacity, and long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

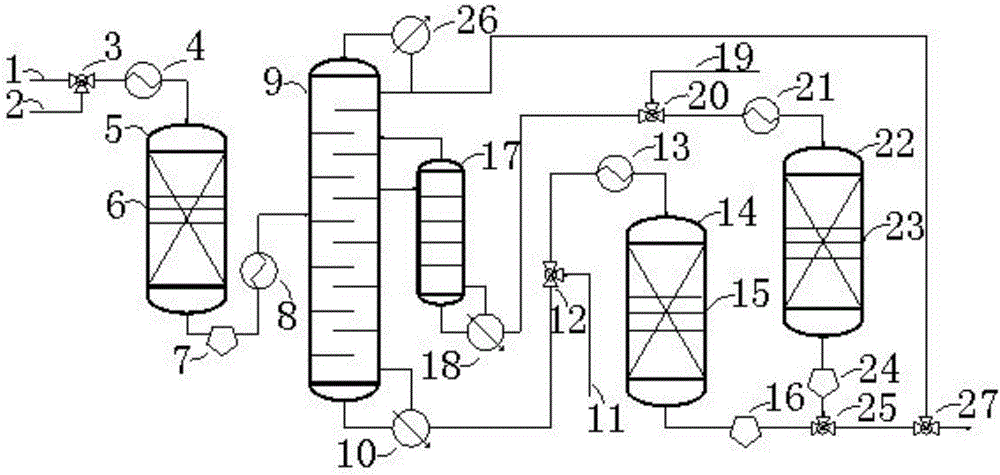

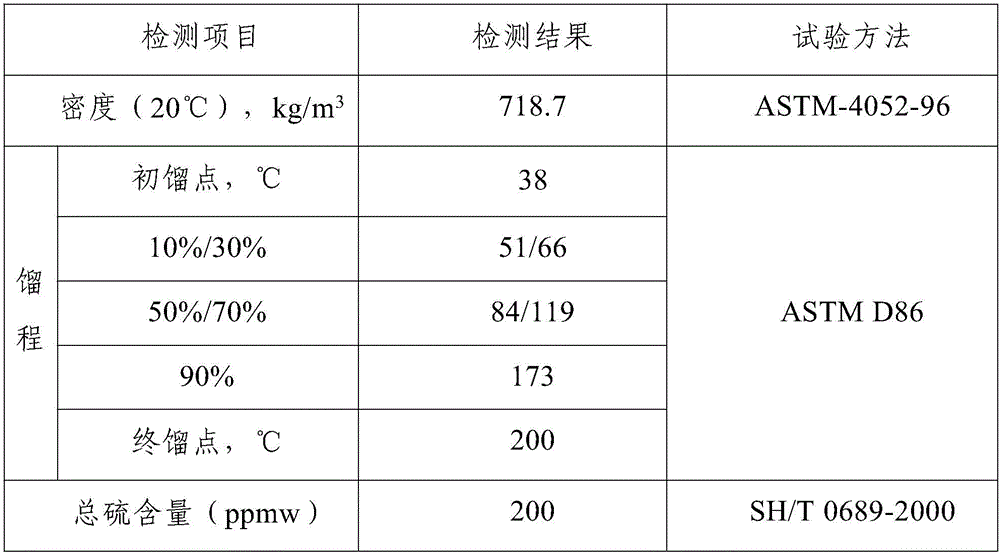

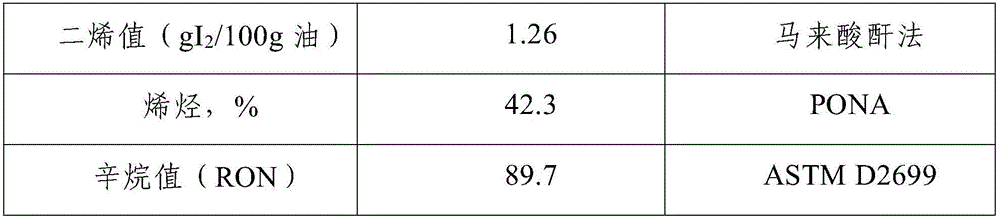

[0092] This example utilizes as figure 1 The device shown in the figure carries out combined desulfurization treatment on the full cut FCC gasoline whose properties are shown in Table 1. The specific treatment method includes the following steps:

[0093] Table 1 Properties of full cut FCC gasoline

[0094]

[0095]

[0096] Step 1. Using full-fraction FCC gasoline and hydrogen as raw materials, hydrogen is mixed through the first pipeline 1 and full-fraction FCC gasoline through the second pipeline 2 into the first mixer 3, and the mixture of the two passes through the first heat exchanger 4. After heat exchange, it enters the diene removal reactor 5, and contacts with the diene removal catalyst 6 in the diene removal reactor 5, so that the whole cut FCC gasoline is subjected to a hydrogenation diene reaction; the hydrogenation diene The reaction conditions are: reaction temperature 80°C, hydrogen partial pressure 1.5MPa, hydrogen-oil volume ratio 100NL / L, liquid hourl...

Embodiment 2

[0103] This example utilizes as figure 1 The device shown in the figure carries out combined desulfurization treatment on the full cut FCC gasoline whose properties are shown in Table 1. The specific treatment method includes the following steps:

[0104] Step 1. Using full-fraction FCC gasoline and hydrogen as raw materials, hydrogen is mixed through the first pipeline 1 and full-fraction FCC gasoline through the second pipeline 2 into the first mixer 3, and the mixture of the two passes through the first heat exchanger 4. After heat exchange, it enters the diene removal reactor 5, and contacts with the diene removal catalyst 6 in the diene removal reactor 5, so that the whole cut FCC gasoline is subjected to a hydrogenation diene reaction; the hydrogenation diene The reaction conditions are: reaction temperature 100°C, hydrogen partial pressure 1.5MPa, hydrogen-oil volume ratio 120NL / L, liquid hourly space velocity 3.0h -1 . Sampling analysis after reacting 500h, find that...

Embodiment 3

[0111] This example utilizes as figure 1 The device shown in the figure carries out combined desulfurization treatment on the full cut FCC gasoline whose properties are shown in Table 1. The specific treatment method includes the following steps:

[0112] Step 1. Using full-fraction FCC gasoline and hydrogen as raw materials, hydrogen is mixed in the first mixer 3 through the first pipeline 1 and the full-fraction FCC gasoline through the second pipeline 2, and the mixture of the two passes through the first heat exchanger 4 After heat exchange, it enters the diene removal reactor 5, and contacts with the diene removal catalyst 6 in the diene removal reactor 5, so that the whole cut FCC gasoline is subjected to a hydrogenation diene removal reaction; The reaction conditions are: reaction temperature 180°C, hydrogen partial pressure 2.0MPa, hydrogen-oil volume ratio 150NL / L, liquid hourly space velocity 3.0h -1 . Sampling analysis after reacting 500h, find that the diene valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com