Improved structure of rotary engine

A technology to improve structure and engine, applied in piezoelectric ignition, electrostatic ignition, machine/engine, etc., can solve the problems of incomplete exhaust gas removal, incomplete power output, slow response speed, etc., to improve exhaust effect and burning time Long, responsive action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable your review committee members to clearly understand the content of the present invention, only the following descriptions are used together with the drawings, please refer to them.

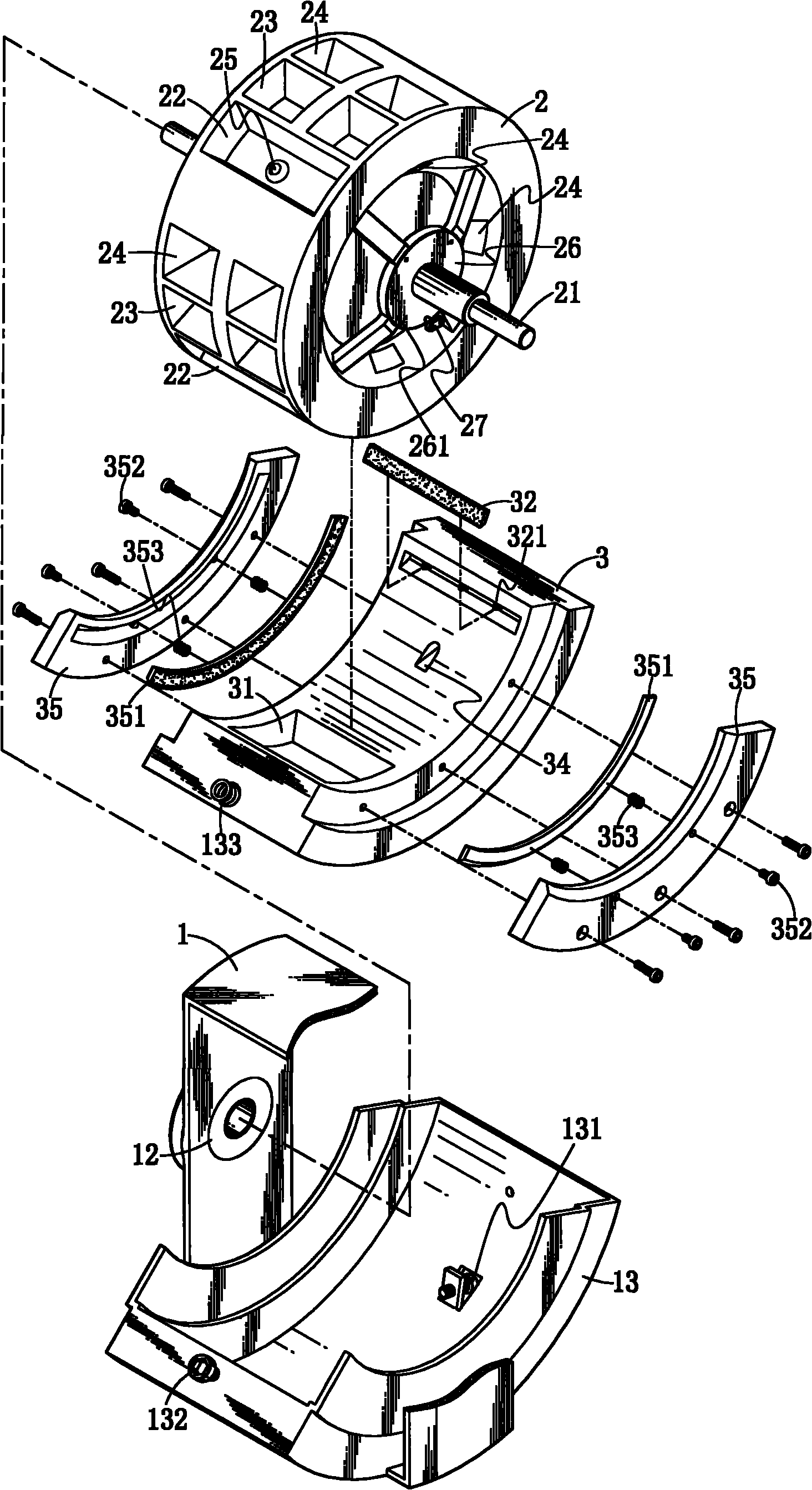

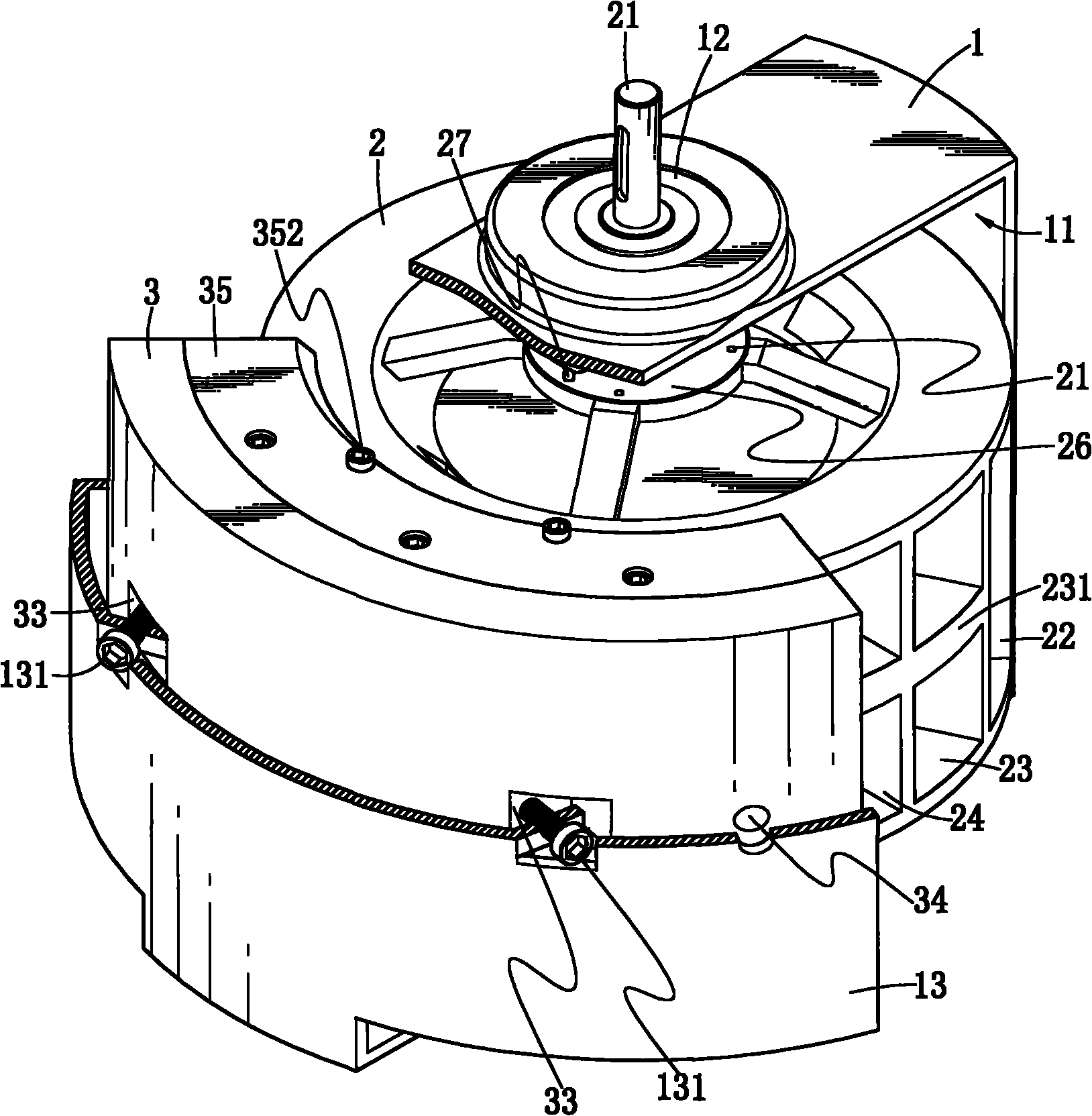

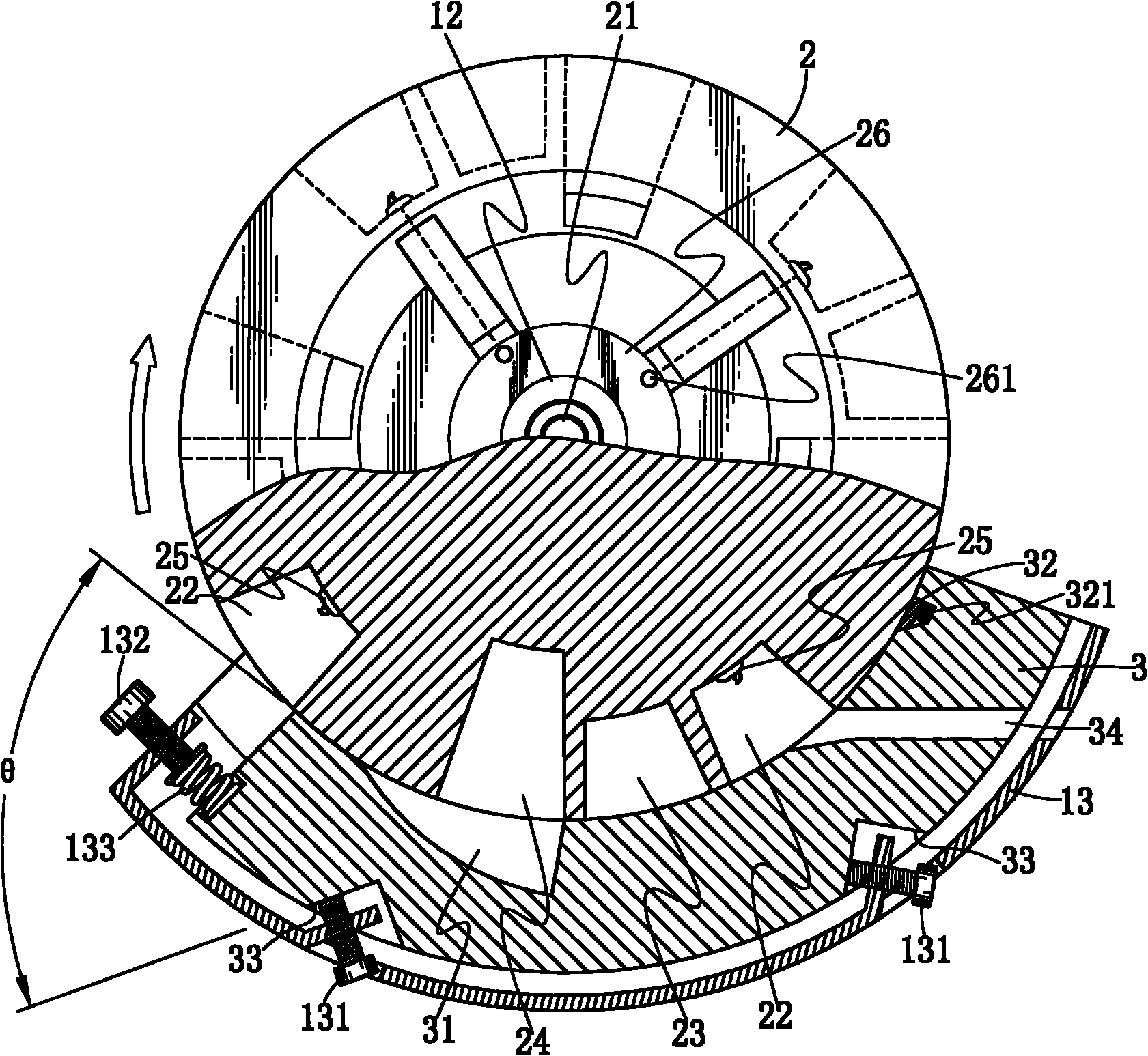

[0026] see Figure 1 to Figure 5 Shown, main structure of the present invention at least comprises following member:

[0027] A frame 1 that is surrounded by a frame has an accommodating space 11 formed in its center, a bearing 12 is provided at the center of the horizontal sections on both sides, and an arc-shaped shell 13 is provided on the vertical section of the frame 1, and the arc-shaped shell A plurality of adjustment screws 131 are provided on the arc surface of the body 13 , and an adjustment screw 132 and a spring 133 are provided on an end edge (exhaust end) of the arc housing 13 .

[0028] A steam turbine 2, the center of which is provided with a main shaft 21, the main shaft 21 is movably installed between the two bearings 12 of the frame 1, and four groups ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com