Full-automatic dynamic solid-liquid separation extractor

A solid-liquid separation and extraction equipment technology, applied in the direction of solid solvent extraction, etc., can solve the problems of uneven extraction temperature, lack of online detection, and low degree of automation of static extraction tank equipment, so as to improve the filtering effect, increase the extraction rate, and improve production Process efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

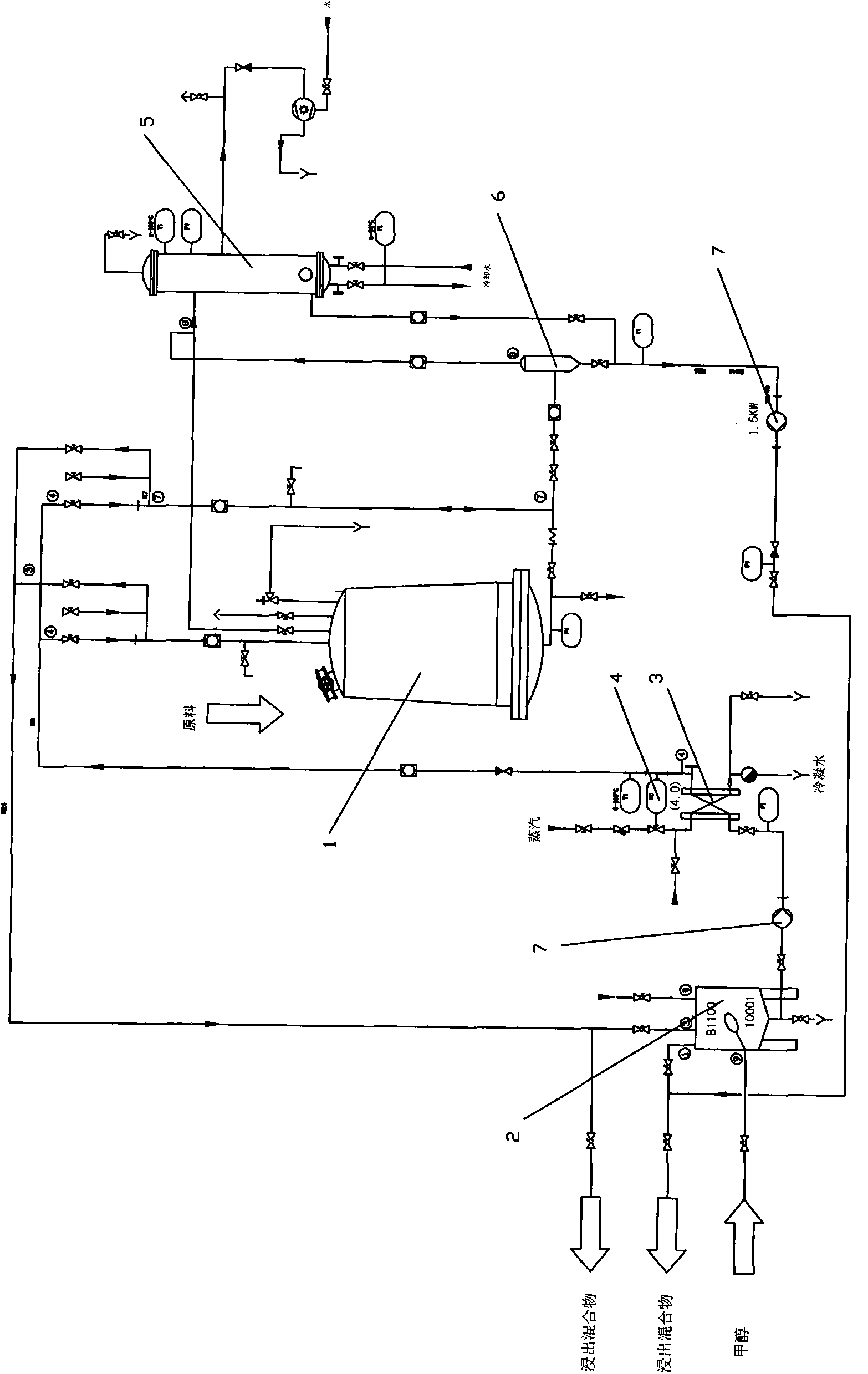

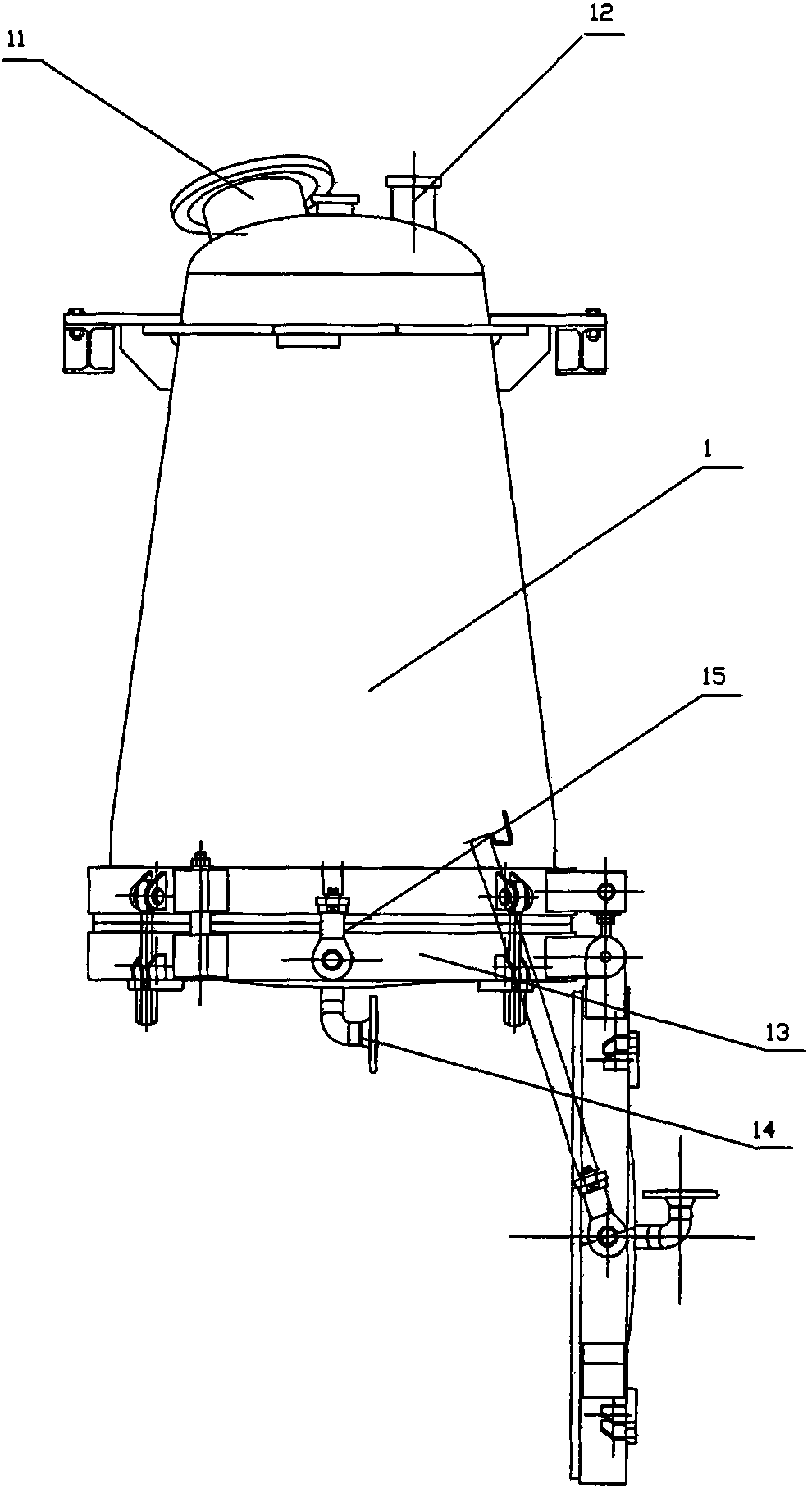

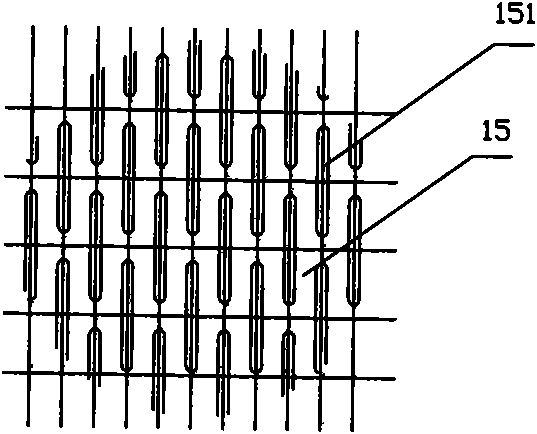

[0010] Such as figure 1 , figure 2 As shown, a full-automatic dynamic solid-liquid separation and extraction device of an embodiment of the present invention includes an extraction tank 1, an extraction liquid temporary storage tank 2, a heat exchanger 3 and a temperature control device 4 thereof, a gas-liquid separator 6, and a recovery solvent condensation Device 5 and computer control system (not shown in the figure). The extraction tank 1 is in the shape of an inverted cone (that is, the lower part of the tank body is larger than the upper part of the tank body), and its taper is 10-30°. One side of the upper part of the tank body is provided with a feed hopper 11, and the other side is provided with an upper liquid inlet and outlet port 12. , the bottom of the tank body is provided with an automatic slag discharge door 13, the automatic slag discharge door 13 is provided with a lower liquid inlet and outlet 14, and the lower liquid inlet and outlet 14 of the automatic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com