Catalyst regeneration method for improving selectivity of catalyst

A catalyst and selectivity technology, applied in catalyst regeneration/reactivation, catalytic cracking, molecular sieve catalysts, etc., can solve the problems of unfavorable catalyst activity, lower catalyst selectivity, high regeneration temperature, etc., and achieve uniform activity distribution and reduced impact , dry gas yield and coke yield reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

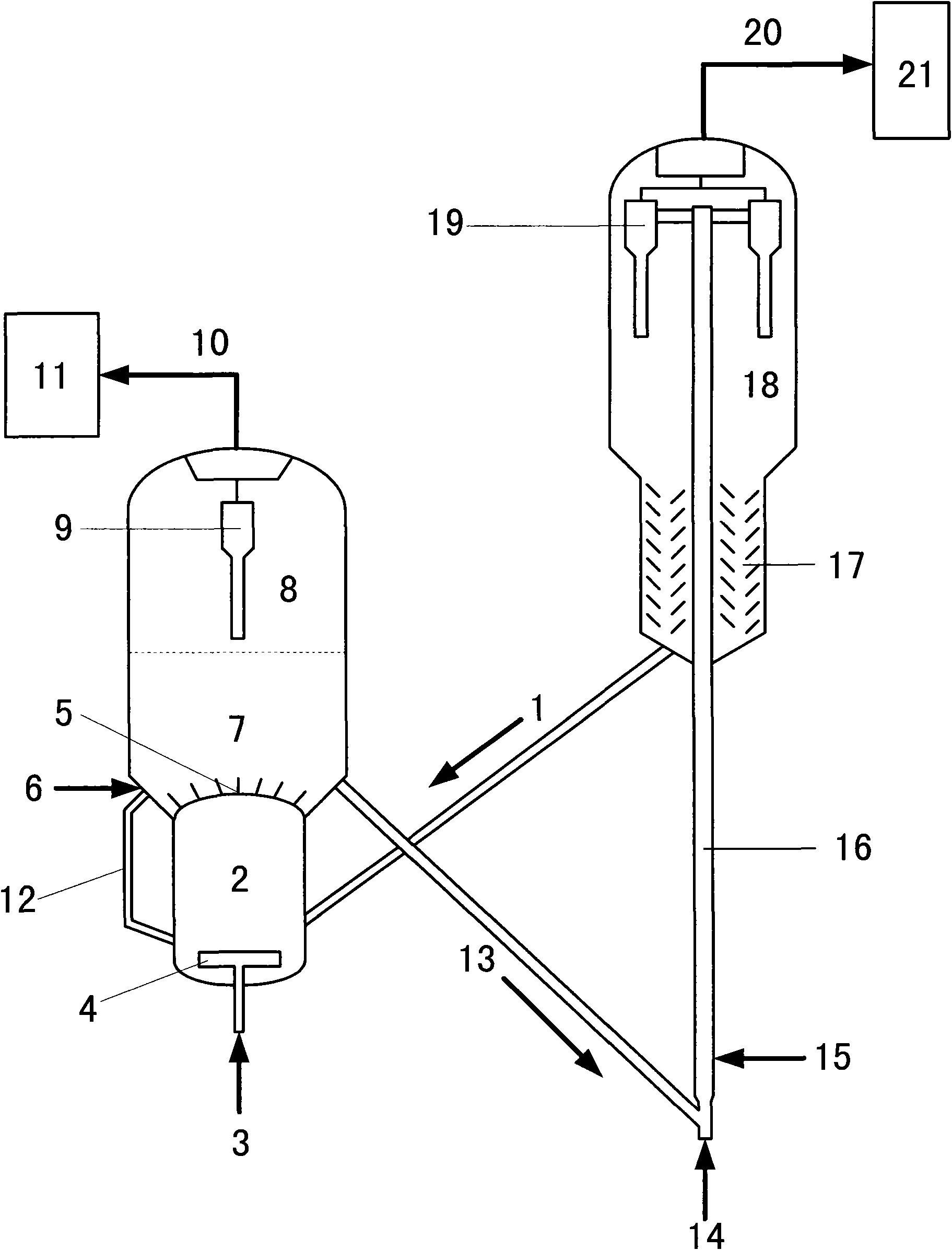

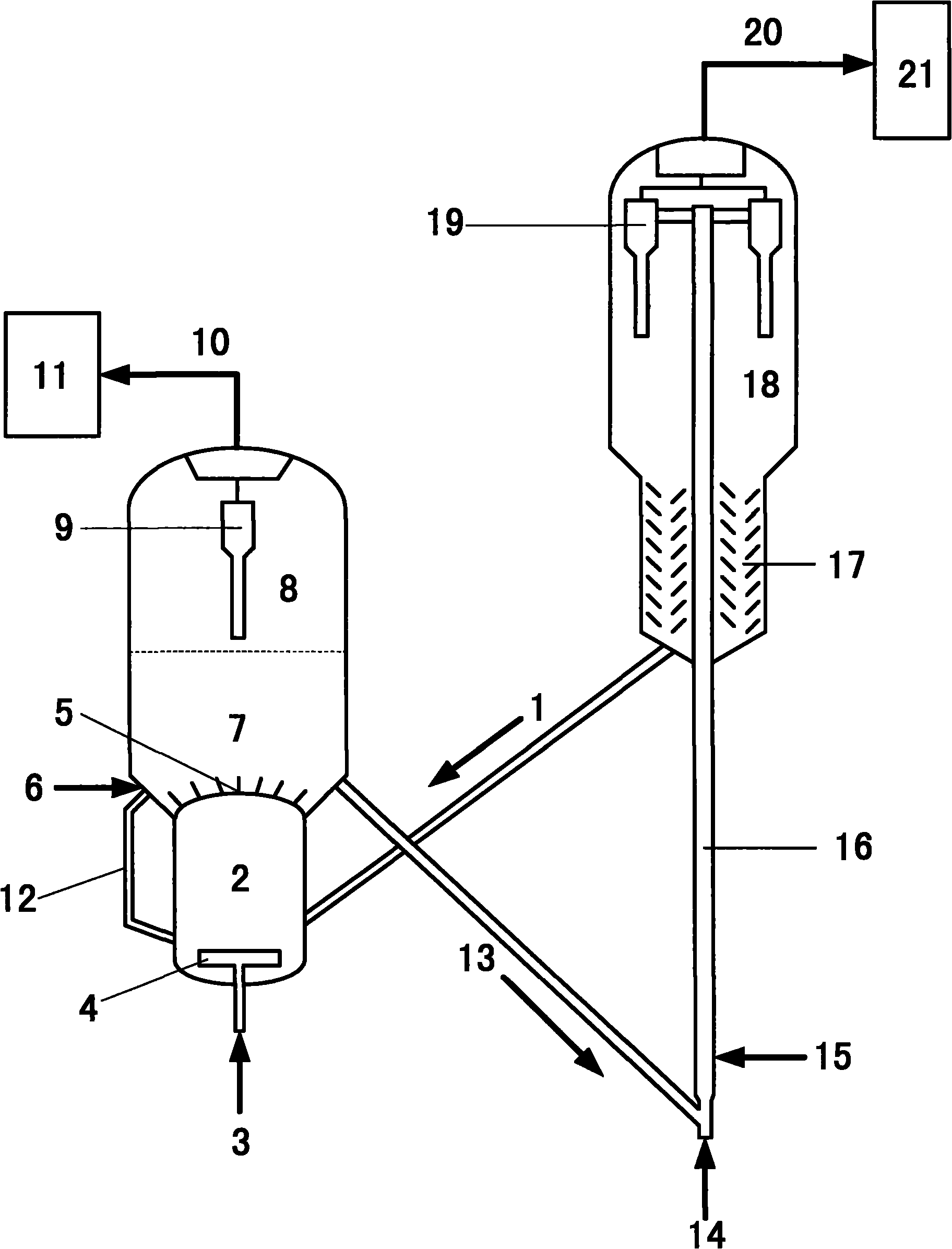

[0031] The embodiment is carried out on a medium-sized catalytic cracking unit, as shown in the accompanying drawing. According to the regeneration method proposed by the present invention, the catalyst is regenerated, the oxygen-containing gas is air, the apparent linear velocity of the gas in the first fluidized bed regenerator is 1.0 m / s, the average residence time of the catalyst is 1.5 minutes, and the regeneration temperature is 680°C ; The superficial linear velocity of the gas in the second fluidized bed regenerator is 0.3 m / s, the average residence time of the catalyst is 15 minutes, and the regeneration temperature is 650°C. The nickel content on the regenerated catalyst is 10000 μg / g, and the regenerated catalyst enters the reactor, contacts with the feed oil listed in Table 1, and carries out catalytic cracking reaction. The regeneration conditions, reaction conditions, regeneration results and reaction results are listed in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com