Multi-stage light well point dewatering construction process for Yellow River flood plain bearing platform construction

A well point dewatering and light well point technology, applied in infrastructure engineering, construction, etc., can solve the problems of long construction period, difficult construction, high cost, etc., and achieve the effect of short construction period, good construction effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

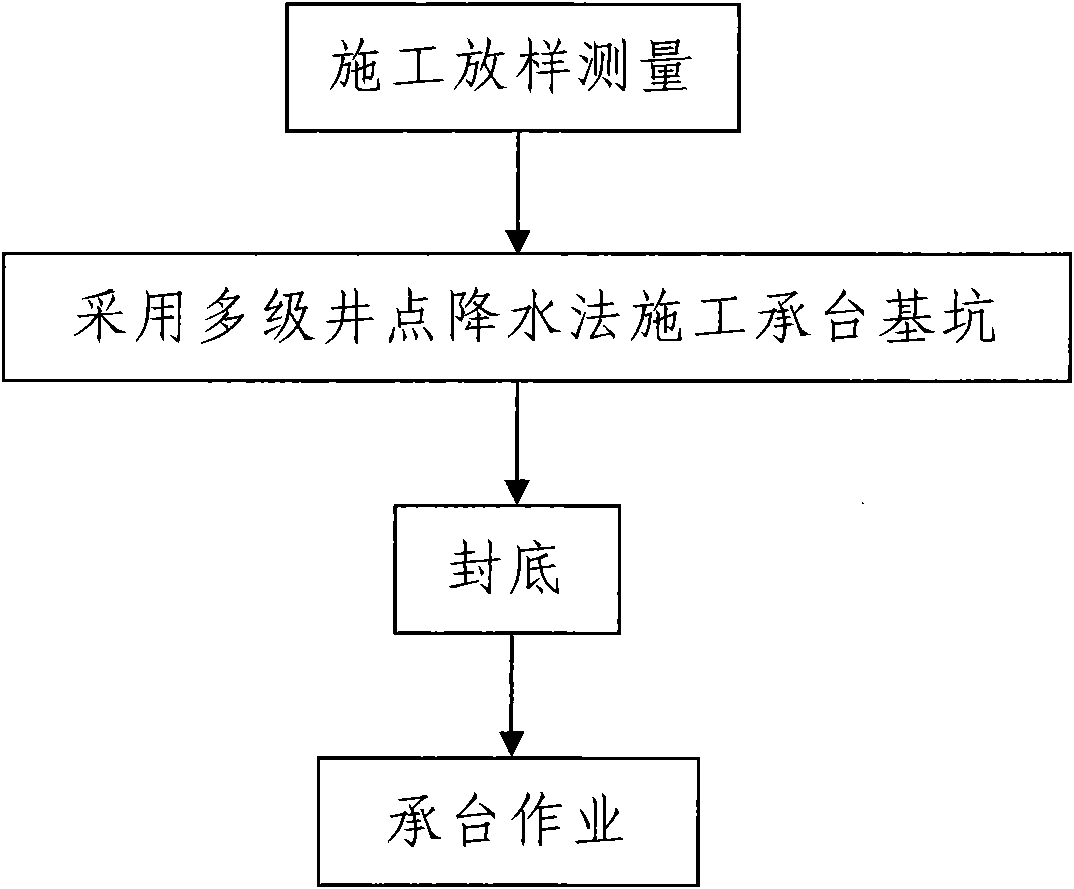

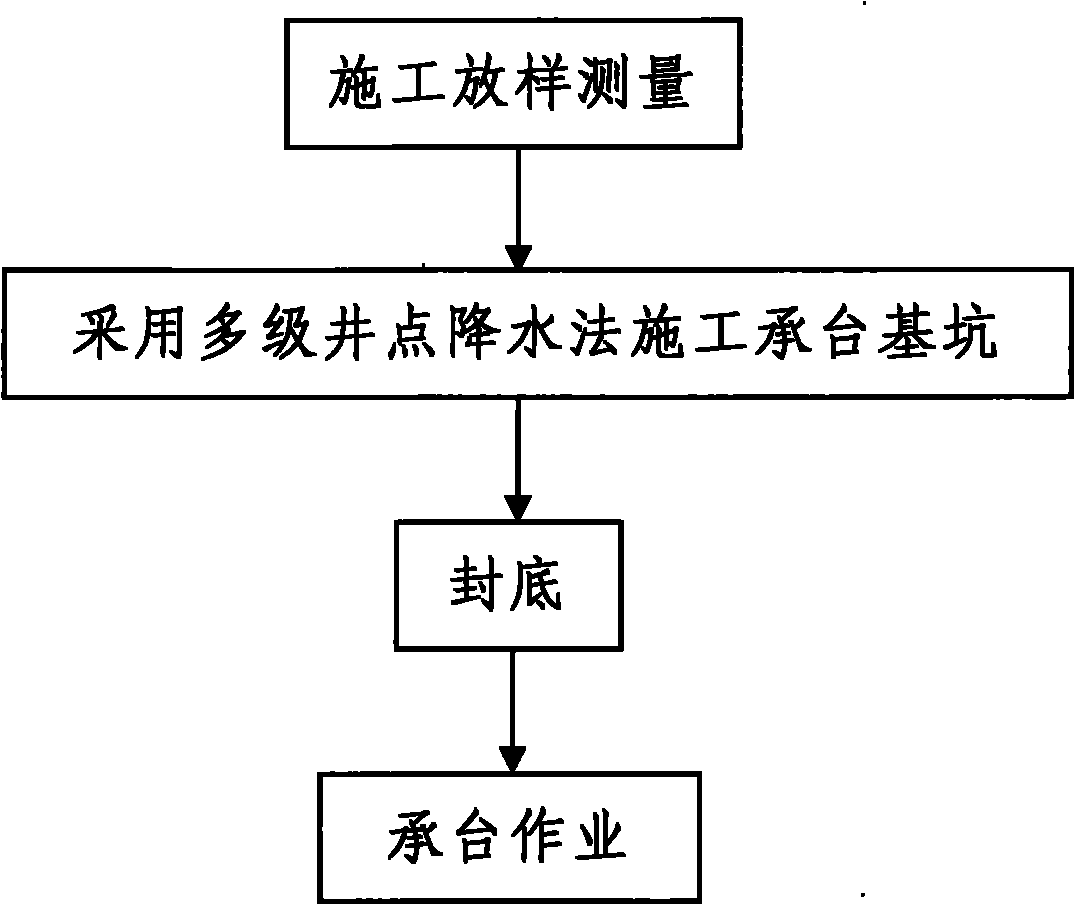

[0045] Such as figure 1 A multi-stage light well-point dewatering construction process for the construction of floodplain caps of the Yellow River is shown. The constructed caps are all located on the floodplains of the Yellow River. The method includes the following steps:

[0046] Step 1. Construction stakeout measurement: Sampling the conventional construction stakeout measurement method, stake out the perimeter lines of the caps to be constructed on the floodplain under construction.

[0047] Step 2. Using the multi-level well point dewatering method to construct the cap foundation pit, the construction process includes the following steps:

[0048] 201. Construction preparation: firstly, according to the distance between the required construction cap and the main river channel of the Yellow River, it is determined how many levels of precipitation need to be carried out. The depth of the water level needs to be reduced, the bottom elevation of the construction cap and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com