Hydraulic cylinder device

A technology for a hydraulic cylinder and a generating device, applied in the field of hydraulic cylinders, can solve the problems such as the inability to achieve the pressure resistance capability and pressure pulse resistance capability of a high-pressure special hydraulic valve, the inability of the differential pressure sensor to meet the high frequency action, and the easy fatigue failure. Achieve powerful computing and coordinated control capabilities, easy adjustment of operating parameters, and wide applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

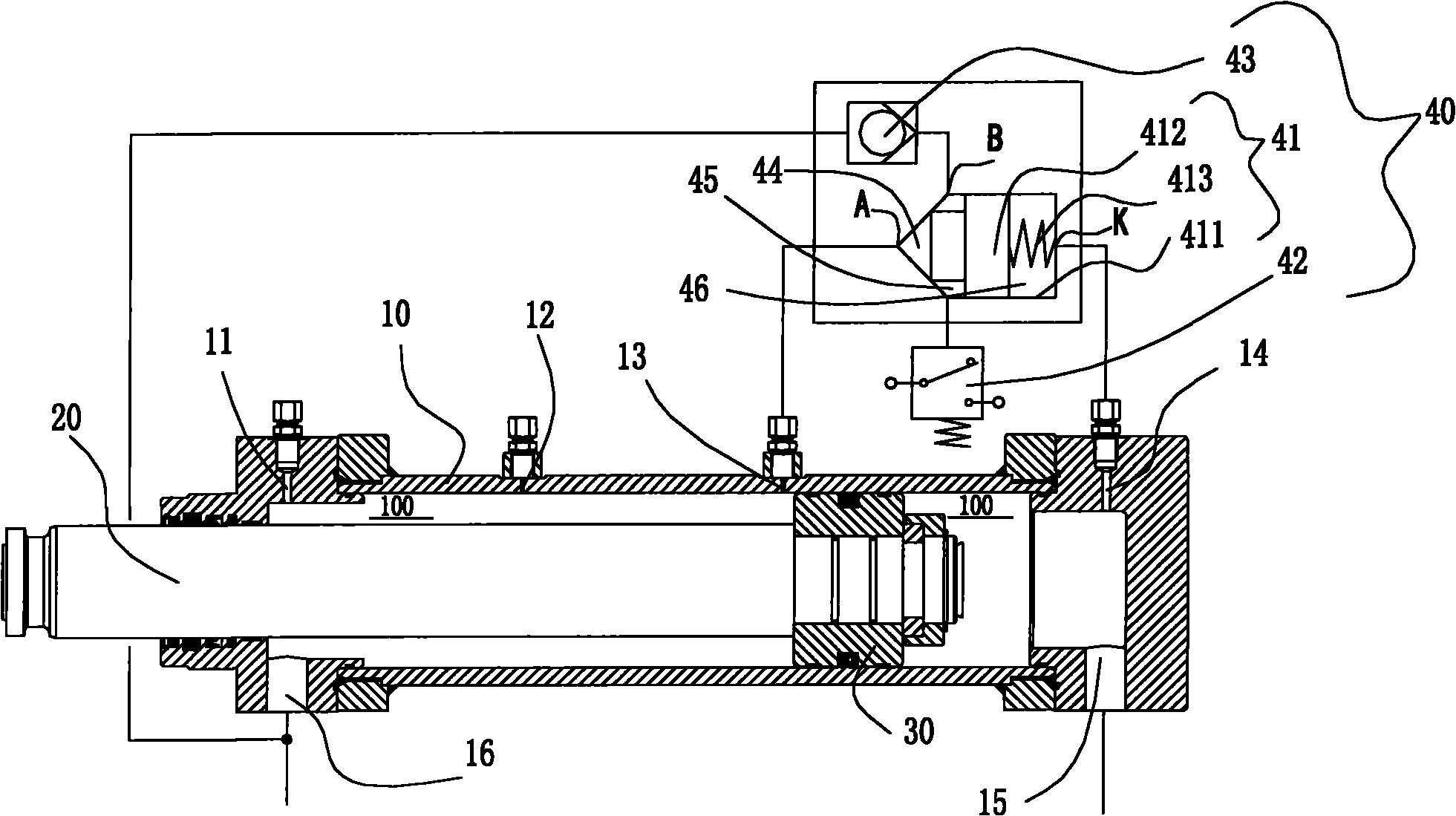

[0025] Such as figure 1 As shown, the hydraulic cylinder device of the present invention includes a cylinder 10, a piston 30 that performs reciprocating linear motion in the cylinder 10, a piston rod 20 that is connected to the piston 30 at one end and extends out of the cylinder 10 at the other end, and a differential pressure electric signal to generate device 40.

[0026] Two ends of the cylinder 10 are respectively formed with an oil inlet and outlet 15 and 16 .

[0027] Both ends of the cylinder 10 have a piston movement intended control area 100. When the piston 30 moves to the piston movement intended control area 100, it is necessary to perform control operations such as buffering or reversing on the movement of the piston 30, each described A differential pressure electrical signal generating device 40 of the present invention is correspondingly provided in the piston motion intended control area 100 (only one differential pressure electrical signal generating device...

no. 2 example

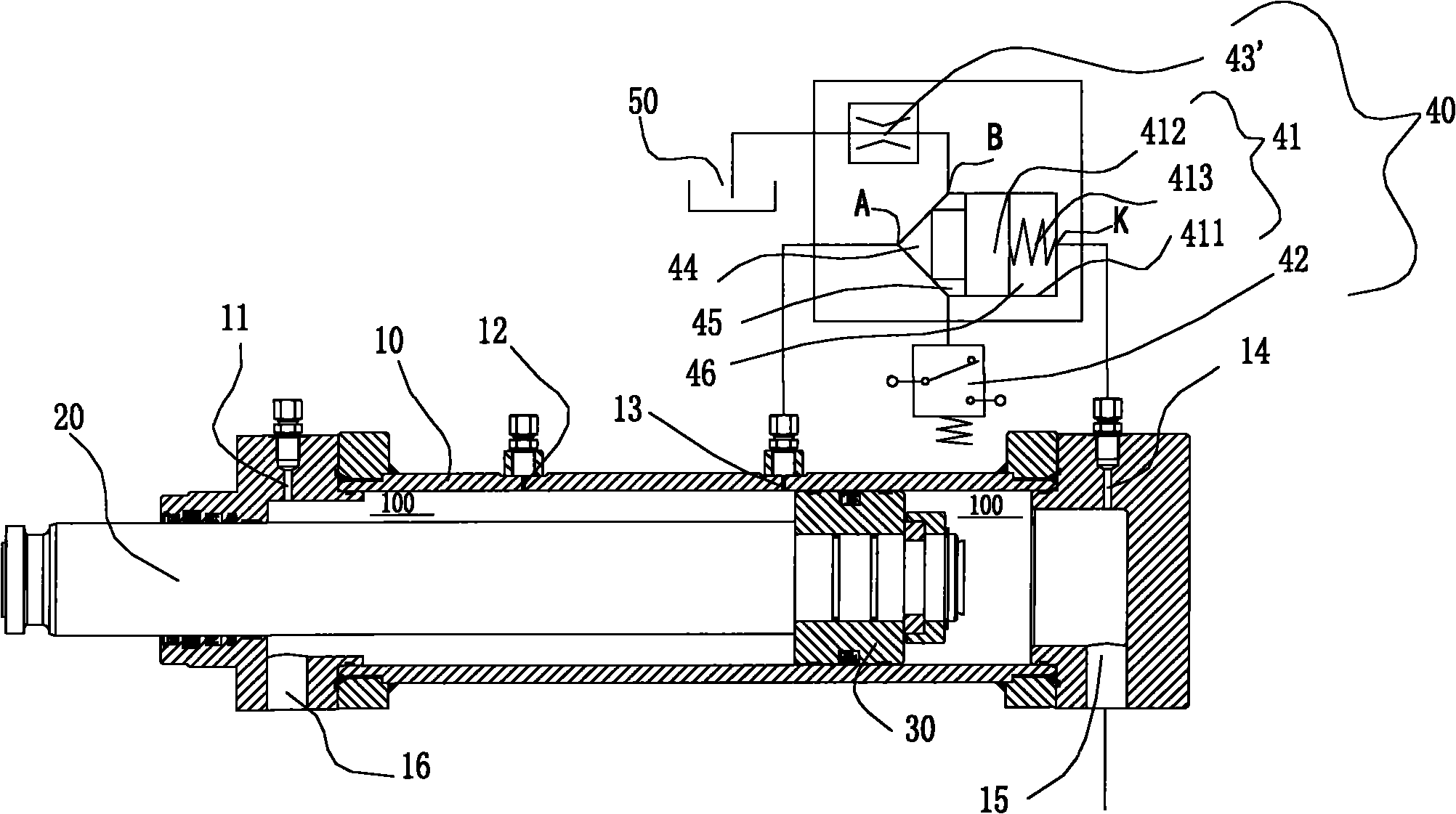

[0041] In the second embodiment, the same reference numerals will be used to designate the same or similar components as much as possible.

[0042] Such as figure 2 As shown, the structure of the second embodiment of the present invention is basically the same as that of the first embodiment of the present invention, the difference between the two is that the one-way valve 43 in the first embodiment is replaced by a damper 43', and the damper The oil drain end of 43' is directly connected to an oil tank 50 by a pipeline. In this embodiment, since the oil drain end of the damper 43' is connected to an oil tank 50 by a pipeline, the pipeline communicating with the oil inlet and outlet 16 on the other side of the cylinder 10 in the first embodiment can be omitted.

[0043] The working process of the second embodiment will be briefly described below.

[0044] When the piston 30 has not yet moved into the intended control area 100 of the piston movement, the signal oil holes 13 ...

no. 3 example

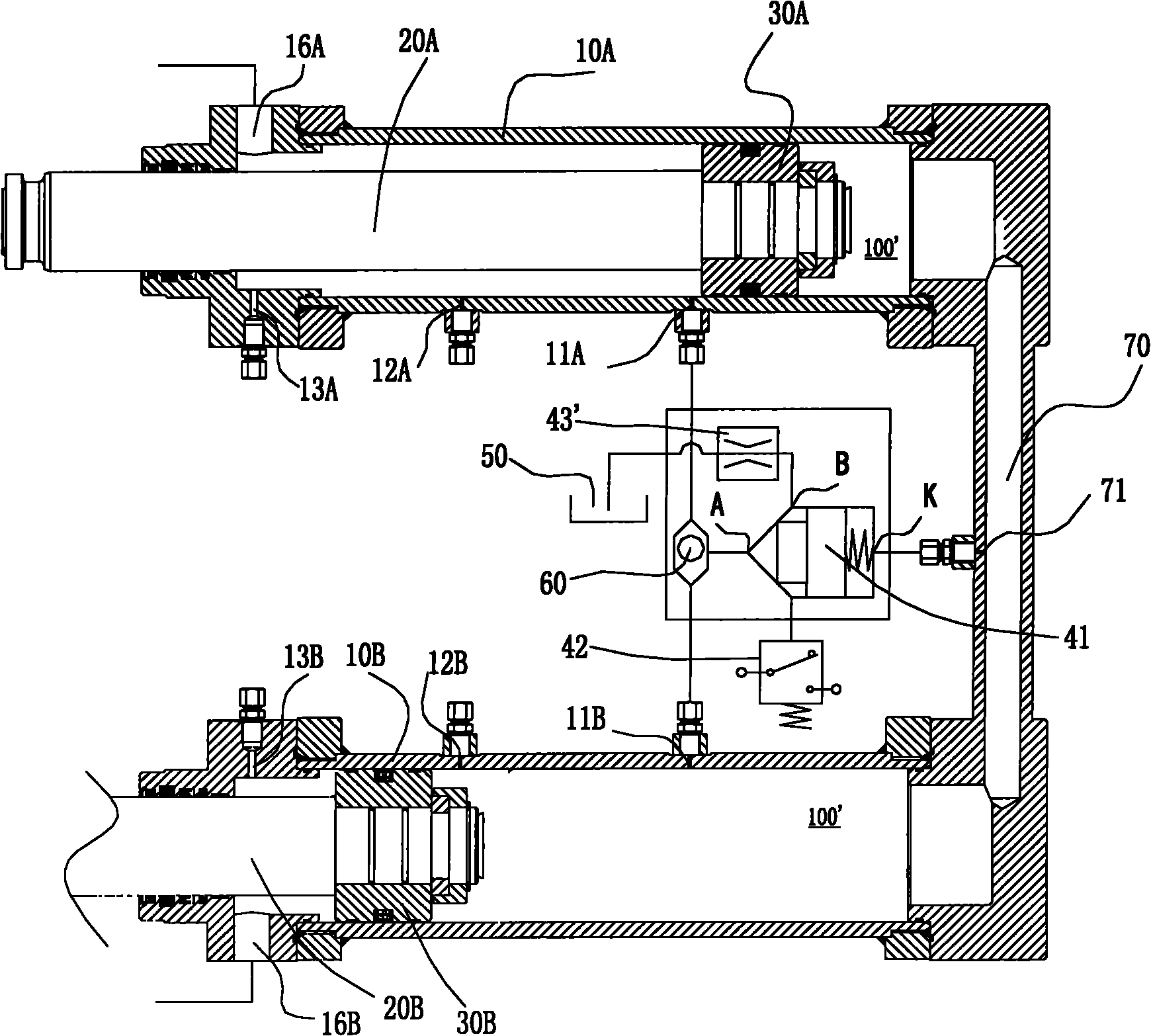

[0048] Such as image 3 As shown, the hydraulic cylinder device according to the third embodiment of the present invention includes a first hydraulic cylinder, a second hydraulic cylinder connected in series with the first hydraulic cylinder, and a differential pressure electric signal generating device.

[0049] The first hydraulic cylinder includes: a cylinder barrel 10A, a piston 30A that performs linear reciprocating motion in the cylinder barrel 10A, and a piston rod 20A that is connected to the piston 30A at one end and extends out of the cylinder barrel 10A at the other end. At the beginning of the piston stroke of the cylinder 10A (ie image 3 The left-hand end of the middle) is formed with a first oil inlet and outlet port 16A, at the end of the piston stroke of the cylinder 10A (ie image 3 There is a piston motion control area 100' at the right-hand end of the center), and a first signal oil hole 11A penetrating through the cylinder wall of the cylinder barrel 10A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com