Preparation method of metal doped organic-inorganic composite SiO2 film

A metal doping, inorganic composite technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problem of insignificant separation effect, and achieve the effect of excellent separation performance and excellent water vapor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

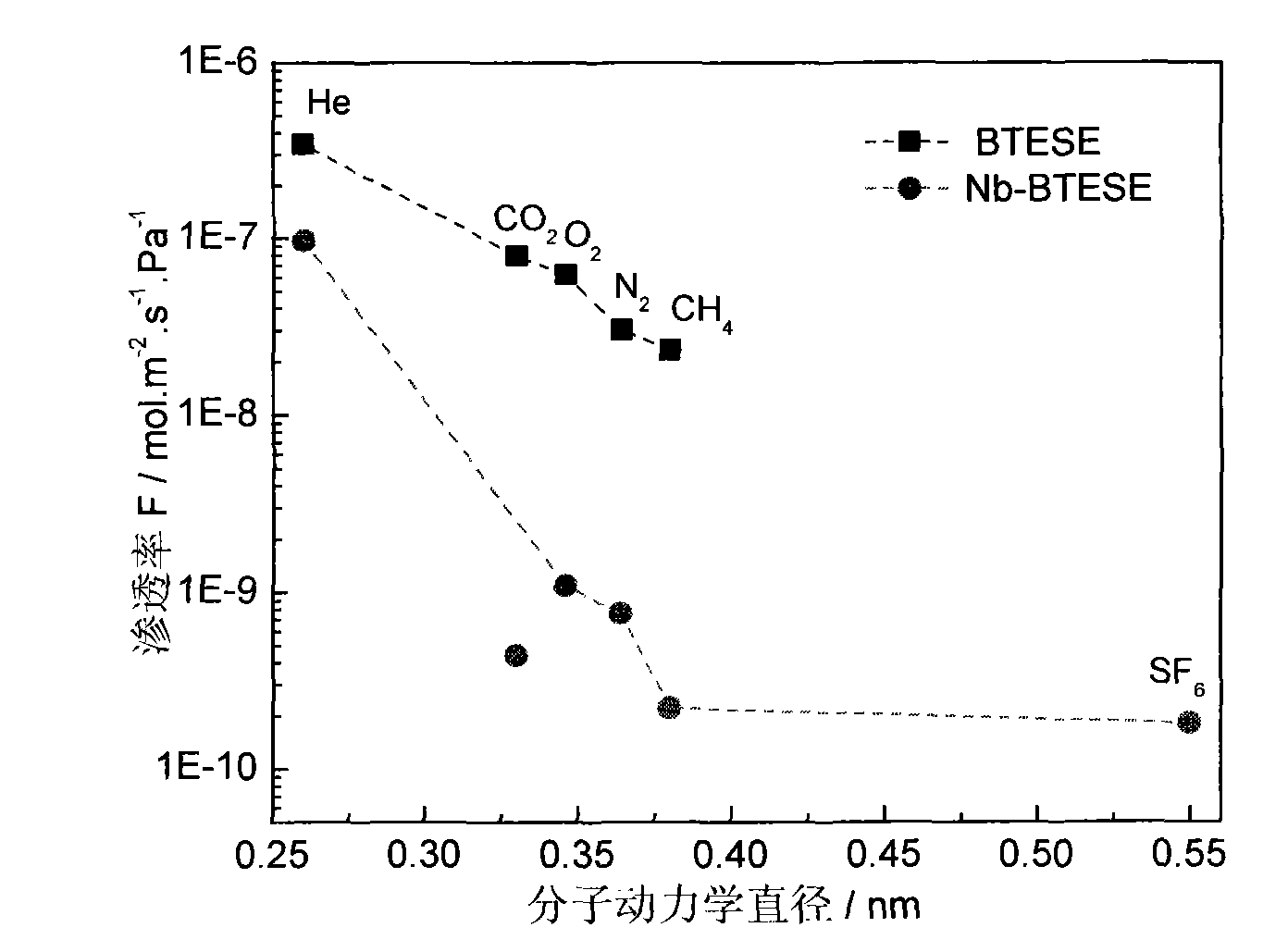

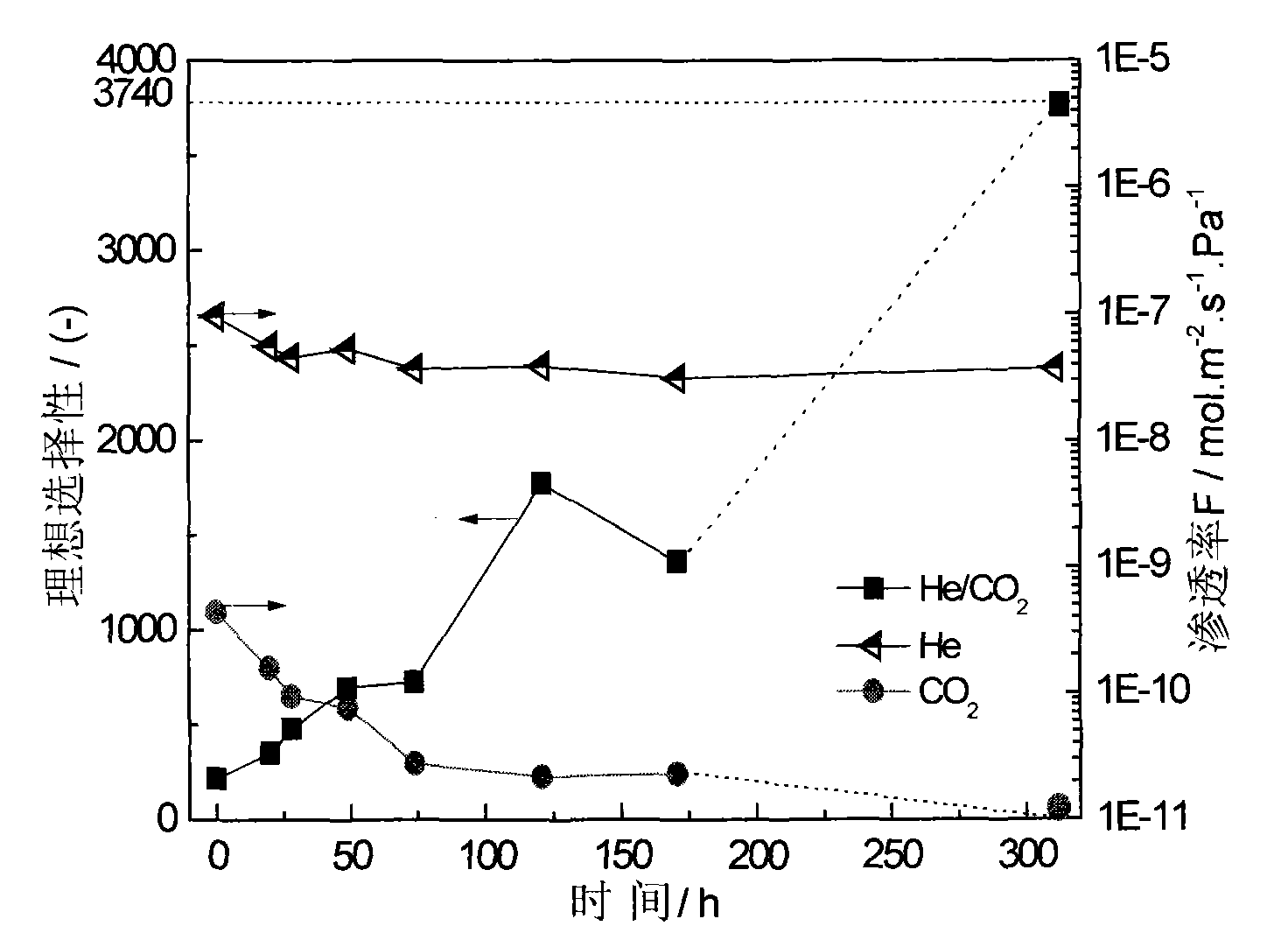

[0019] Embodiment 1, with BTESE and Nb (OC 4 h 9 ) 5 Nb-doped organic-inorganic composite SiO as precursor 2 Preparation of Membrane Nb-BTESE

[0020] Mix 5ml of BTESE and 30ml of absolute ethanol and place in an ice bath at 0°C, add 0.6ml, 1mol / l HCl solution to it under stirring conditions, stir and mix evenly, and place in a constant temperature water bath at 60°C, After reacting for 1.5 hours, take it out and place it in an ice bath at 0°C, add 7ml of Nb(OC 4 h 9 ) 5 and 35ml of absolute ethanol, after mixing evenly, continue to add 0.6ml of 1mol / l HCl solution, and then react in a constant temperature water bath at 60°C for 1.5 hours. After the reaction, a transparent Nb-doped organic-inorganic composite SiO was obtained 2 Sol. Store it at -20°C until use. Mix the sol and absolute ethanol at a volume ratio of 1:8 to obtain a film-forming solution, and place the film-forming solution in a sheet-shaped γ-Al 2 o 3 Membrane surface coating, natural dried flake Nb-d...

Embodiment 2

[0023] Embodiment 2, with tetraethyl orthosilicate (TEOS) and tetraethyl titanate (Ti(OC 2 h 5 ) 4 ) as the precursor of Ti-doped organic-inorganic composite SiO 2 Preparation of Membrane Ti-TEOS

[0024] Mix 10ml TEOS and 20ml butanol in an ice bath at -10°C, add 1.8ml, 1.5mol / l HNO3 solution to it under stirring, stir and mix evenly, then place in a constant temperature water bath at 70°C , after reacting for 2 hours, take it out and place it in an ice bath at -10°C, add 2ml Ti(OC 2 h 5 ) 4 and 20ml of ethanol, after mixing evenly, continue to add 1.8ml, 1.5mol / l of HNO 3 solution, and then reacted in a constant temperature water bath at 70°C for 2 hours. After the reaction, a transparent Ti-doped organic-inorganic composite SiO was obtained. 2 Sol. Store it at -20°C until use. The sol and butanol were mixed at a volume ratio of 1:10 to obtain a film-forming solution, and the film-forming solution was placed in the flake TiO 2 Membrane surface coating, naturally d...

Embodiment 3

[0025] Example 3, using 1,2-bis(triethoxysilyl)methane (BTESM) as a precursor to incorporate Co(NO 3 )·6H 2 Preparation of Co-doped organic-inorganic composite SiO by O 2 Membrane Co-BTESM

[0026] Mix 5ml of BTESM and 45ml of methanol in an ice bath at -20°C, and add 6ml of 0.5mol / l H 2 SO 4 solution, stirred and mixed evenly, placed in a constant temperature water bath at 55°C, reacted for 1 hour, took it out and placed it in an ice bath at -20°C, added 15.7g Co(NO 3 )·6H 2 O and 60ml of ethanol, after mixing evenly, continue to add 6ml, 0.5mol / l of H 2 SO 4 solution, and then reacted in a constant temperature water bath at 55°C for 1 hour. After the reaction, a Co-doped organic-inorganic composite SiO with a transparent appearance was obtained. 2 Sol. Store it at -20°C until use. The sol and methanol were mixed at a volume ratio of 1:3 to obtain a film-forming solution, and the film-forming solution was placed in a sheet of ZrO 2 Membrane surface coating, natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com