Novel automatic feed plate cutting mechanism

An automatic feeding and shearing technology, which is applied in the direction of shearing devices, shearing machine equipment, shearing machine accessories, etc., can solve the problems of low precision, low labor efficiency, troublesome cutting width adjustment, etc., and achieve high adjustment accuracy , high labor productivity, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

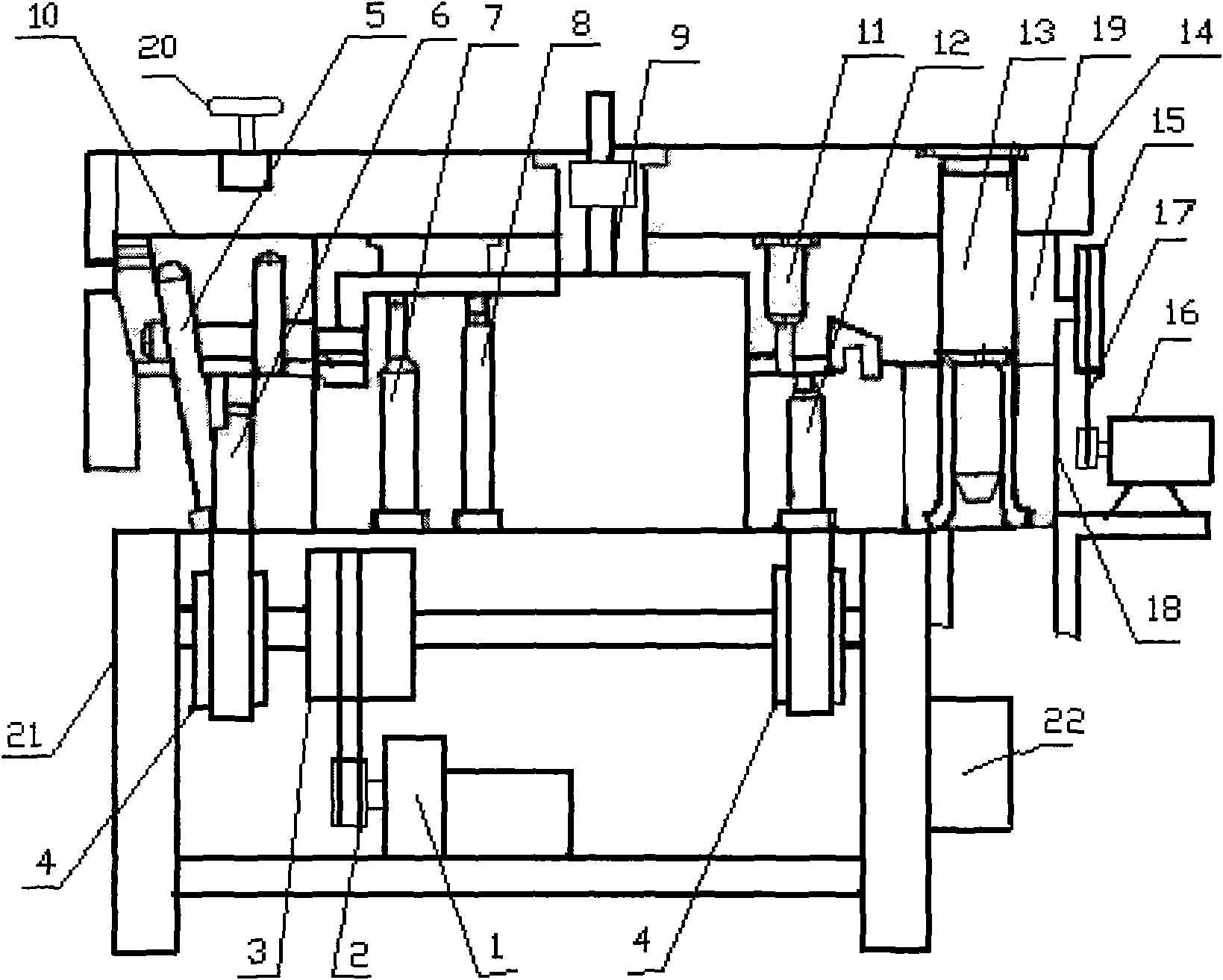

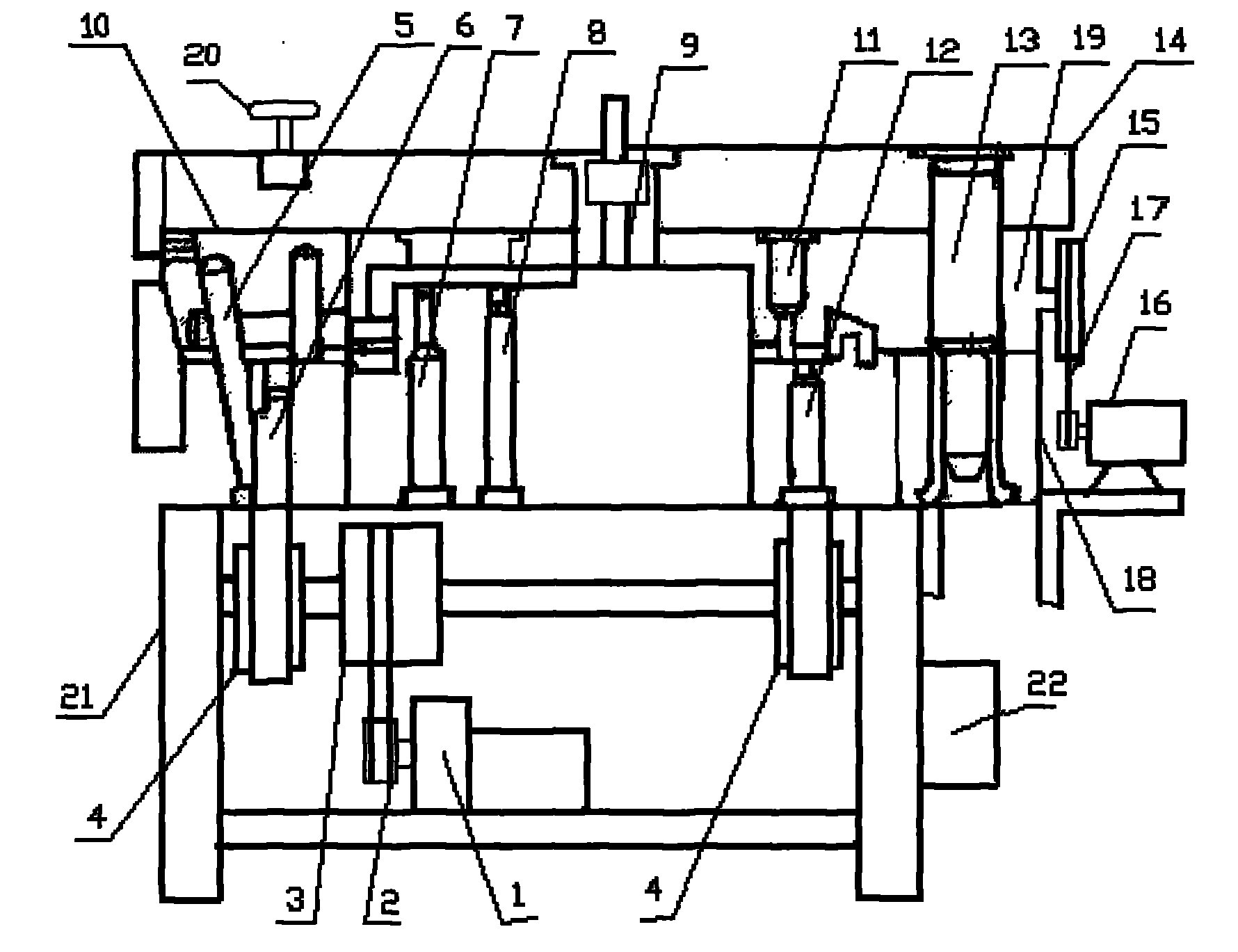

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] The present invention consists of a reducer (1), a crank slider mechanism, a press-lift roller mechanism, an upper shaft roller (11), a lower shaft roller (12), a stepping motor (16) and a program controller (22). (1) Connected with the motor, the reducer (1) transmits the motion of the motor to the main shaft through the motor pulley (2) and the large pulley (3), and a pair of eccentric wheels (4) in the crank slider mechanism are fixed on At both ends of the main shaft, the eccentric wheel (4) drives the upper knife rest (10) through the connecting rod, and the upper knife rest (10) then reciprocates up and down, and the pressing mechanism is connected with the upper knife rest (10). The material plate (7) and the stage clip (9) are composed, the stepper motor (16) drives the lower shaft roller (12) through the sprocket (15), the stepper motor (16) is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com