Device for machining plastic preforms into plastic containers with format recognition

A technology of plastic preforms and plastic containers, which is applied in the field of plastic container equipment, can solve the problems of returned goods, production loss and production bottles, and achieve the effect of accurate matching and simplified production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The technical solutions of the present invention will be further described below in conjunction with the examples, but the present invention is not limited thereto.

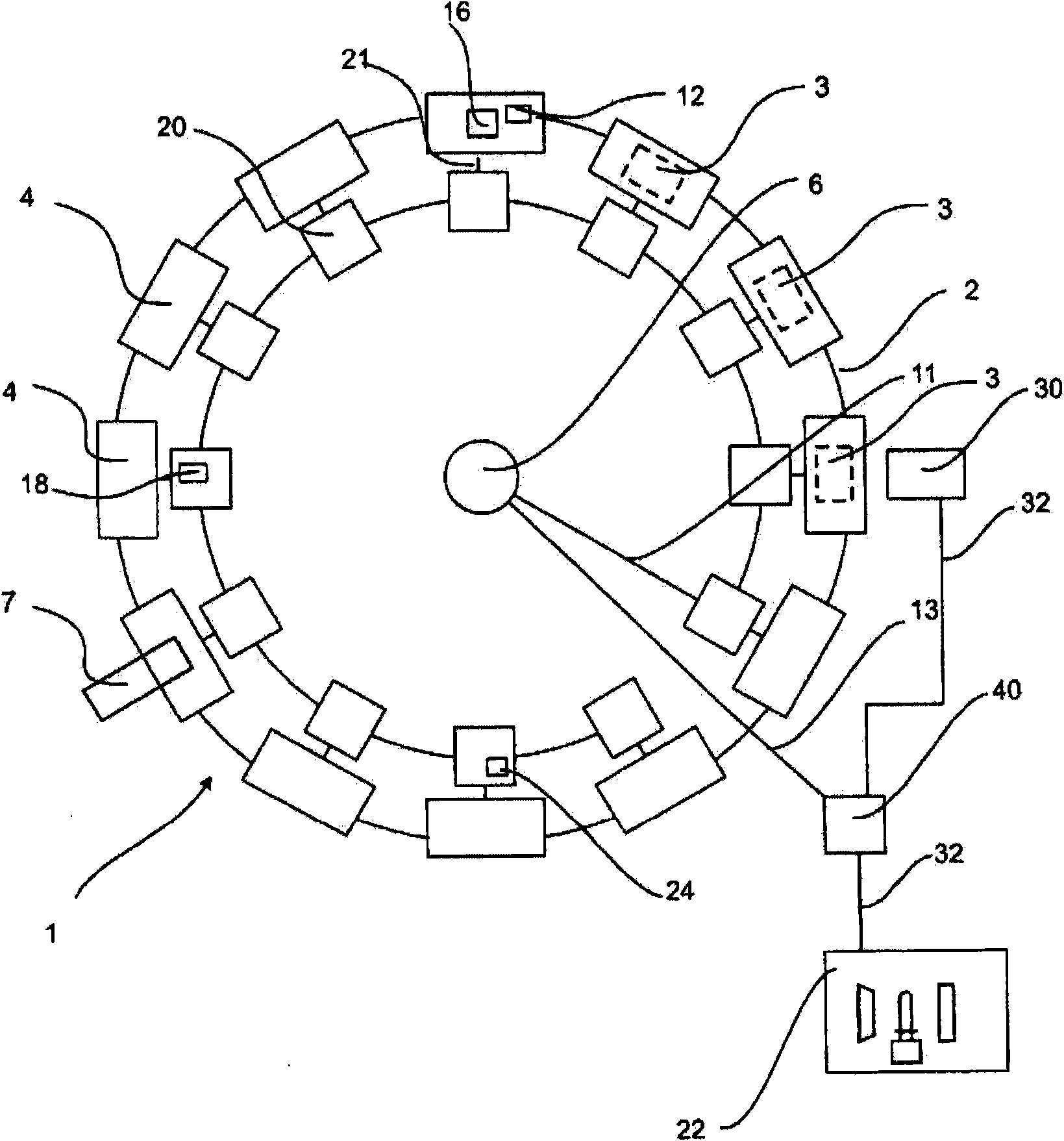

[0064] figure 1 A device 1 for producing plastic containers according to the invention is schematically shown. The device has a conveyor device 2 (shown only schematically) in the form of a blow molding wheel, wherein a plurality of blow molding stations 4 for expanding the preforms are distributed over the blow molding wheel. Reference numeral 20 designates a control device or servo converter respectively assigned to the individual blow molding stations. The individual control devices 20 are thus distributed (rotatably) over the blow molding wheel 2 . The power supply of the control device takes place via a slip ring designated with reference numeral 6 and a connecting line 11 .

[0065] Each blow molding station 4 has a drive 16 for a crossbar (not shown) and valves 12 which control the actual blow mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com