Low-temperature gas spectral measurement device and use method thereof

A spectral measurement and low temperature technology, applied in the direction of measuring device, color/spectral characteristic measurement, spraying device, etc., can solve the problem of no testing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

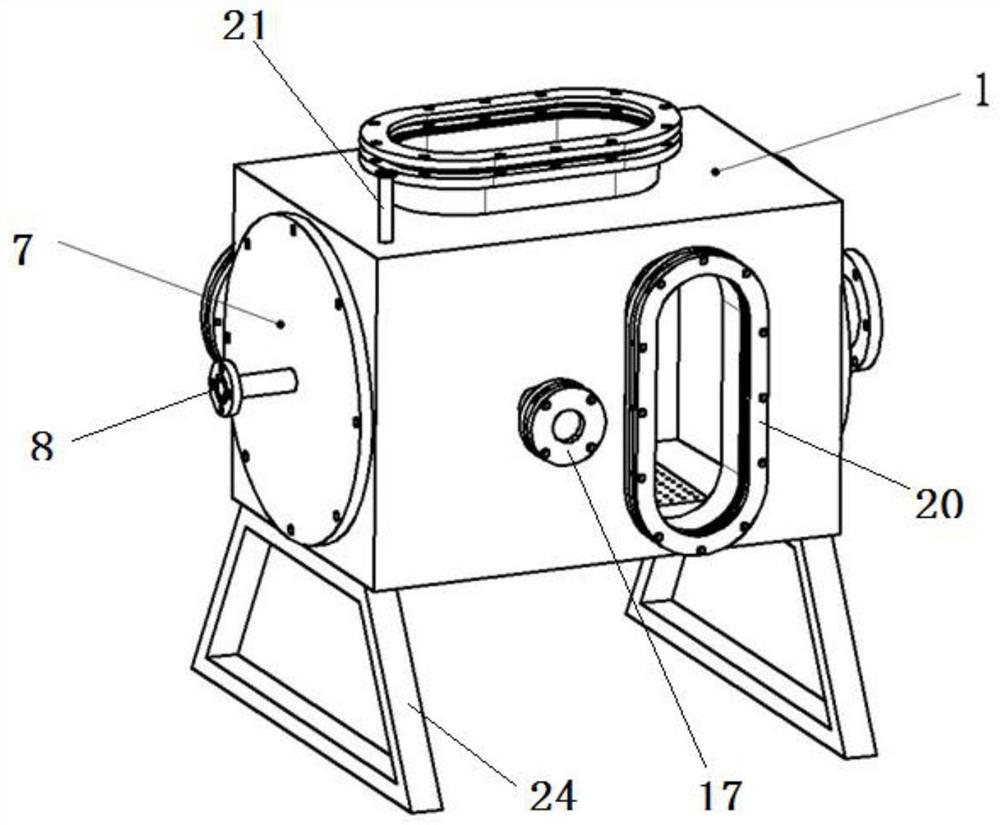

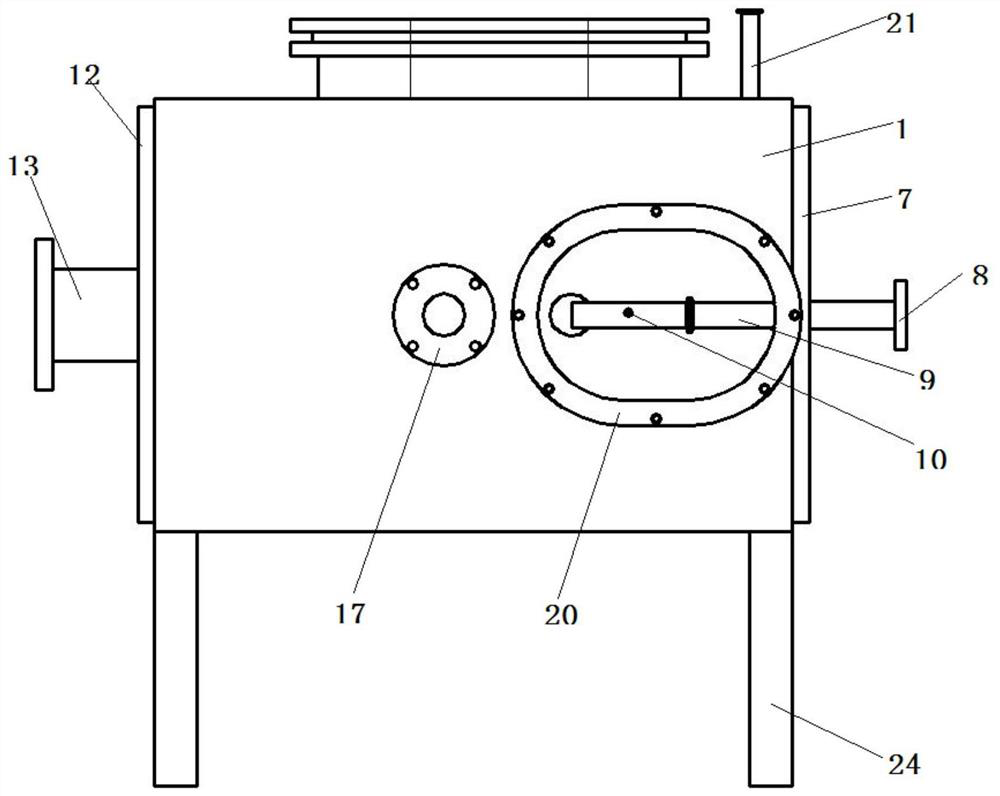

[0044] A low-temperature mixed gas spectrum measurement device, including a rectangular parallelepiped tank body 1 providing physical space for low-temperature mixed gas spectrum measurement, and a gas inlet 2 for mixed gas introduction on the tank body 1, and a gas inlet 2 for mixed gas export The gas outlet 3, the incident light hole 4 for laser incidence and the exit light hole 5 for laser reception;

[0045] The gas inlet 2 and the gas outlet 3 are respectively arranged on the symmetrical two ends of the tank body 1, and the incident light hole 4 and the output light hole 5 are respectively arranged on the front and back sides of the tank body 1 Above, the entrance light hole 4 and the exit light hole 5 are equipped with flanges;

[0046] Specifically, the tank body 1 is welded by steel plates to provide the required physical space for spectral measurement, and its interior is blackened to avoid diffuse reflection from affecting spectral measurement;

[0047] Specifically...

Embodiment 2

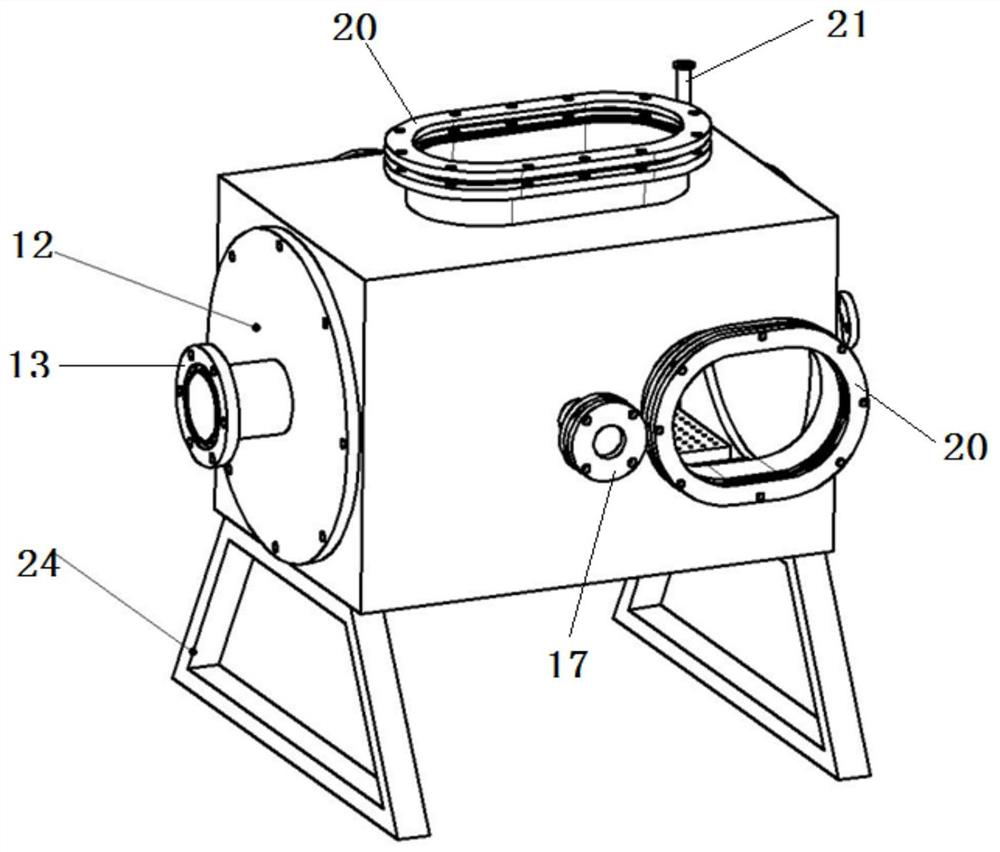

[0054] This embodiment introduces its observation window on the basis of Embodiment 1.

[0055] The tank body 1 is also provided with an observation window 6 , and a borosilicate glass window 18 is hermetically installed on the outer side of the observation window 6 . The borosilicate glass window 18 is sealed and installed on the tank body 1 through the observation window gasket 19 and the observation window flange cover plate 20 .

[0056] Specifically, the viewing window 6 includes a front viewing window 6-1, a rear viewing window 6-2 and an upper viewing window 6-3, which are located on the front, rear and top surface of the tank body 1, respectively. The front observation window 6-1, the rear observation window 6-2 and the upper observation window 6-3 are all elongated through holes, and borosilicate glass windows 18 are installed on their outer sides, and the borosilicate glass windows 18 The observation window gasket 19 and the observation window flange cover plate 20 ...

Embodiment 3

[0058] This embodiment introduces its screw plate 23 on the basis of Embodiment 1.

[0059] The screw plate base 22 is eight fixed blocks made of rectangular parallelepiped stainless steel, four fixed blocks form a group, and are divided into two groups and welded symmetrically on the inner bottom surface of the tank body 1, and each group of fixed blocks is installed with one The screw plate 23; the top of the fixed block is processed with threaded holes, the four corners of the screw plate 23 are provided with strip holes 23-1, and the bolts pass through the strip holes 23-1 and the top of the fixed block The threaded holes cooperate to install the screw plate 23 on the fixing block; the four elongated holes 23-1 on the screw plate 23 can adjust the installation position of the screw plate 23 back and forth to meet the installation position requirements of the reflector.

[0060] The screw hole plate 23 is a rectangular steel plate with uniformly distributed threaded holes p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com