Temperature field simulation method and device for composite material automobile brake disc

A composite material, automotive braking technology, applied in design optimization/simulation, constraint-based CAD, special data processing applications, etc., can solve the problems of poor thermal conductivity, high material density, no square matrix method of temperature field, etc. The effect of design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

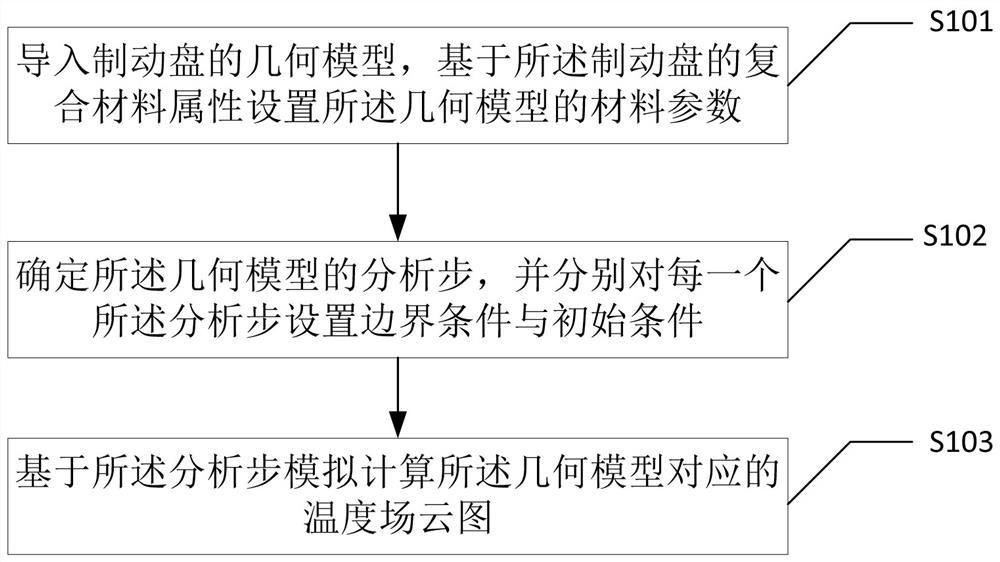

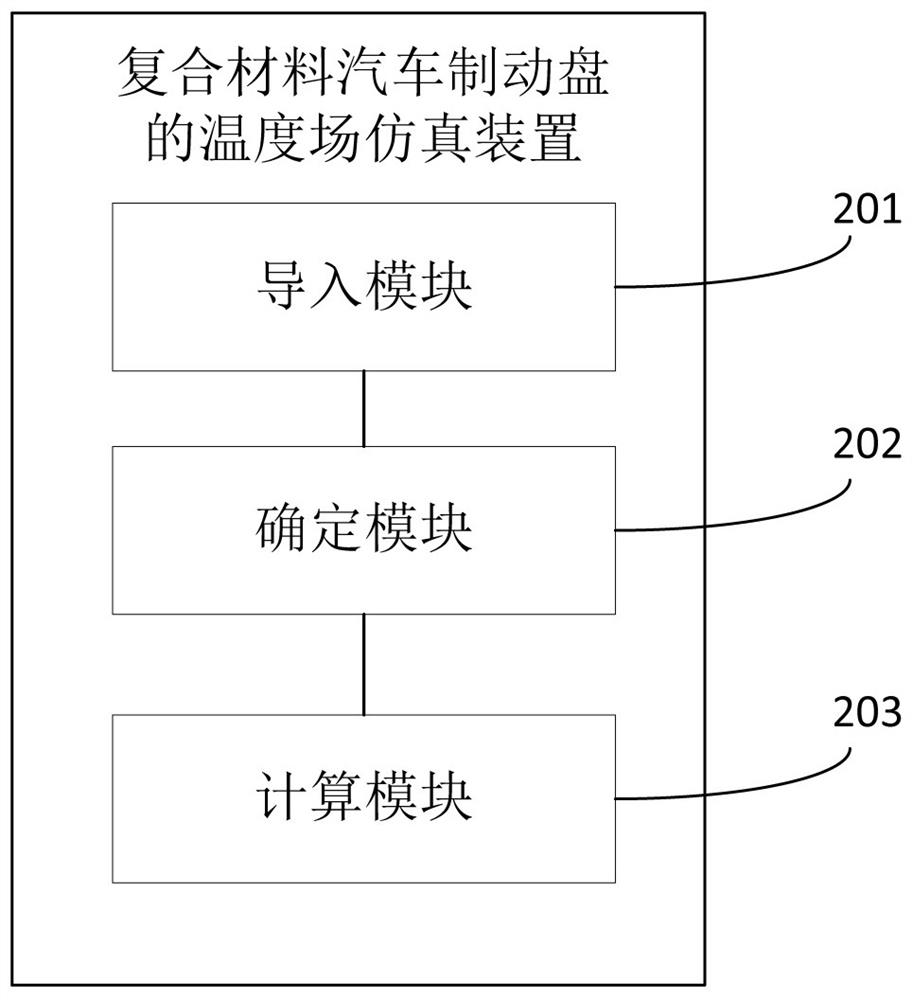

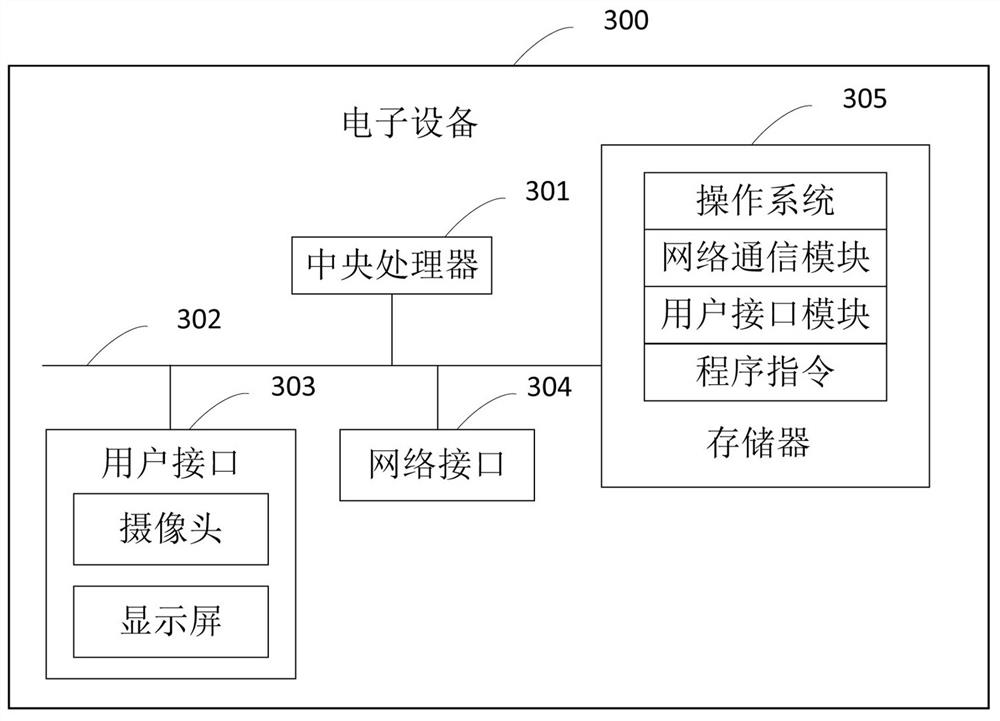

[0040] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

[0041] In the following introduction, the terms "first" and "second" are only used for the purpose of description, and should not be understood as indicating or implying relative importance. The following introduction provides multiple embodiments of the present application, and different embodiments can be replaced or combined and combined, so the present application can also be considered to include all possible combinations of the same and / or different embodiments described. Thus, if one embodiment contains features A, B, C, and another embodiment contains features B, D, then the application should also be considered to include all other possible combinations containing one or more of A, B, C, D Although this embodiment may not be clearly written in the following content....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com