Electrified railway in-phase power supply device

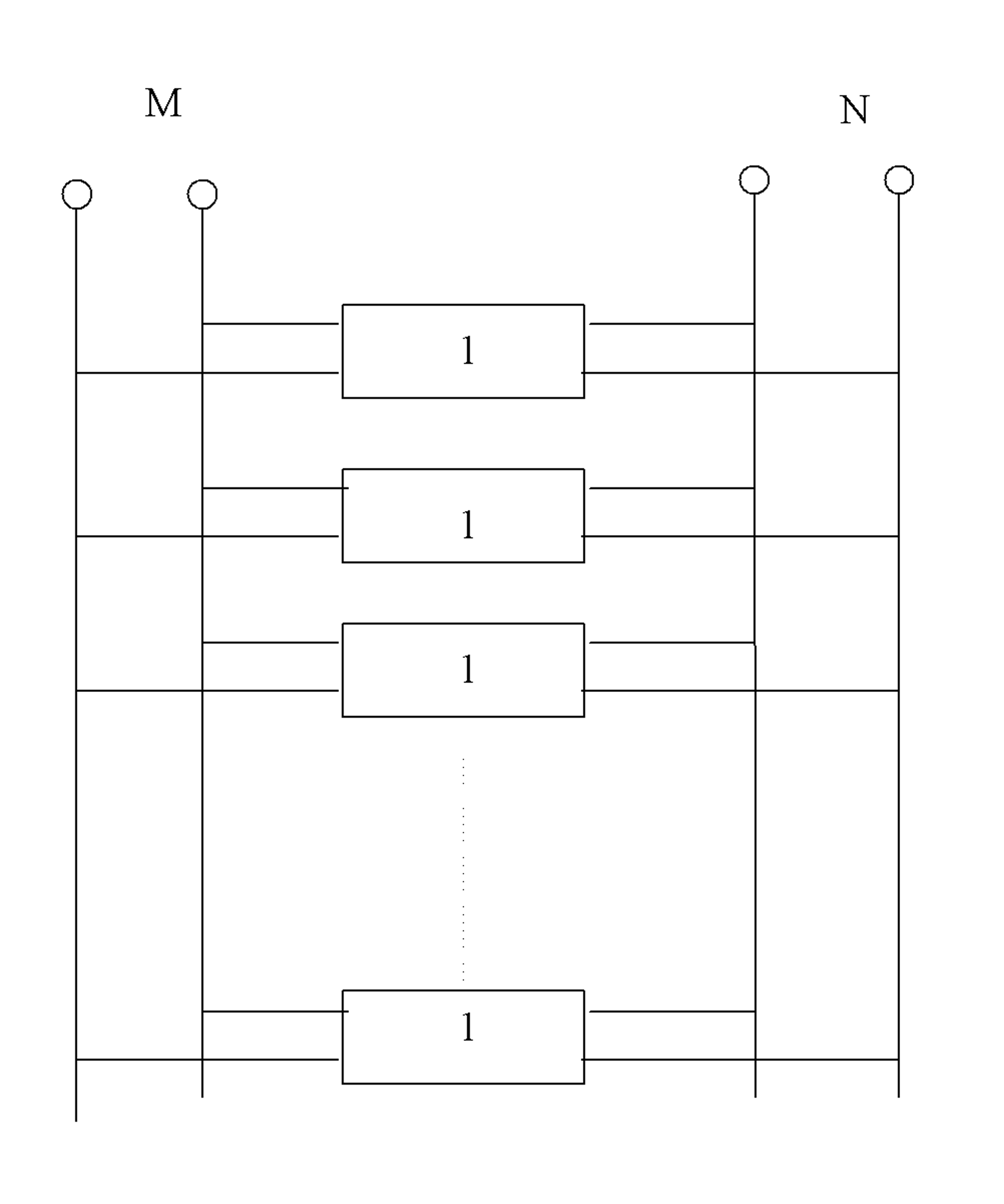

A technology for electrified railways and in-phase power supply, which is applied in the direction of power lines, transportation and packaging, and conversion equipment for intermediate conversion to DC, which can solve the problems of poor scalability and increase the difficulty of design and maintenance, so as to increase scalability and improve stability sex, reducing the effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

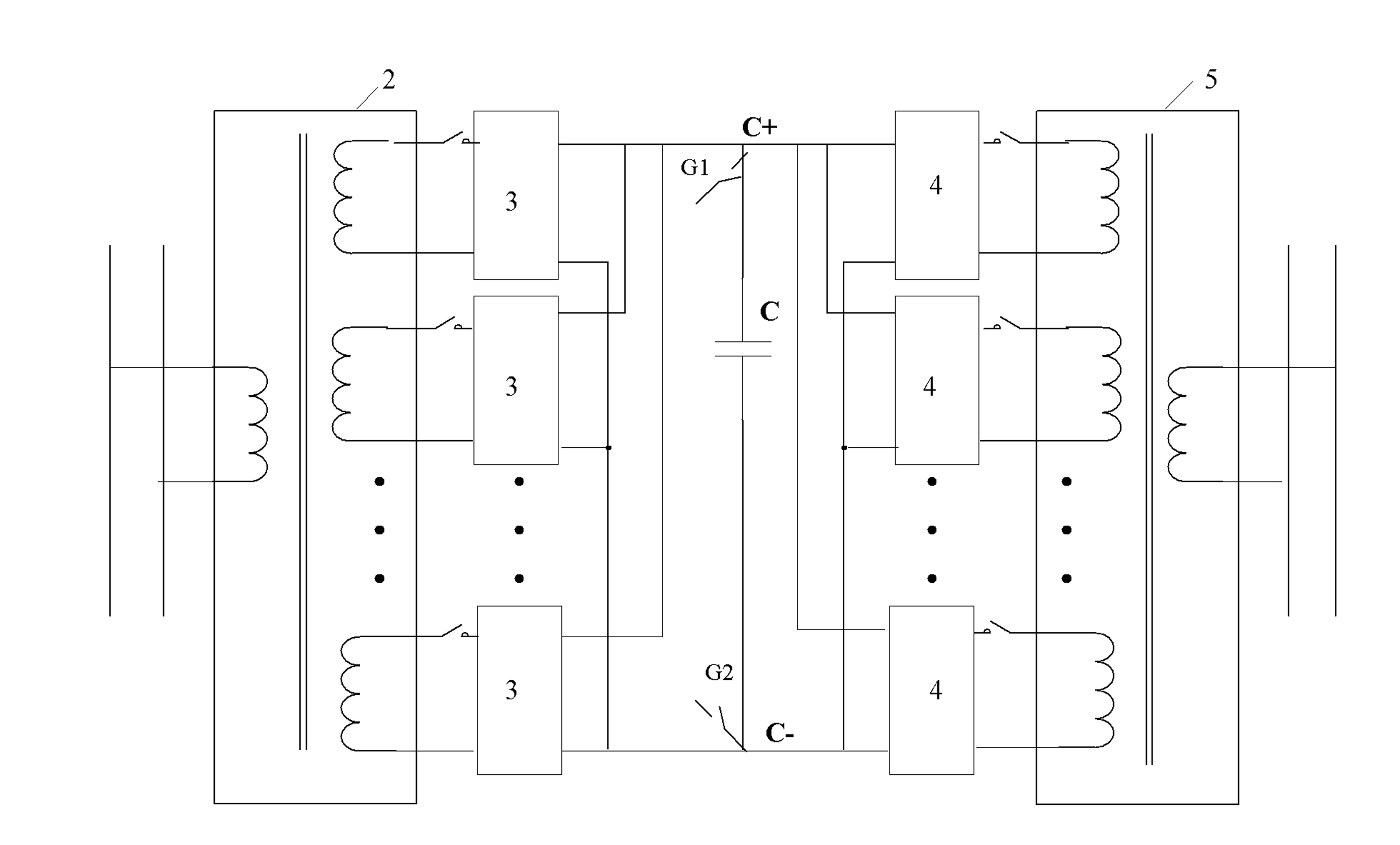

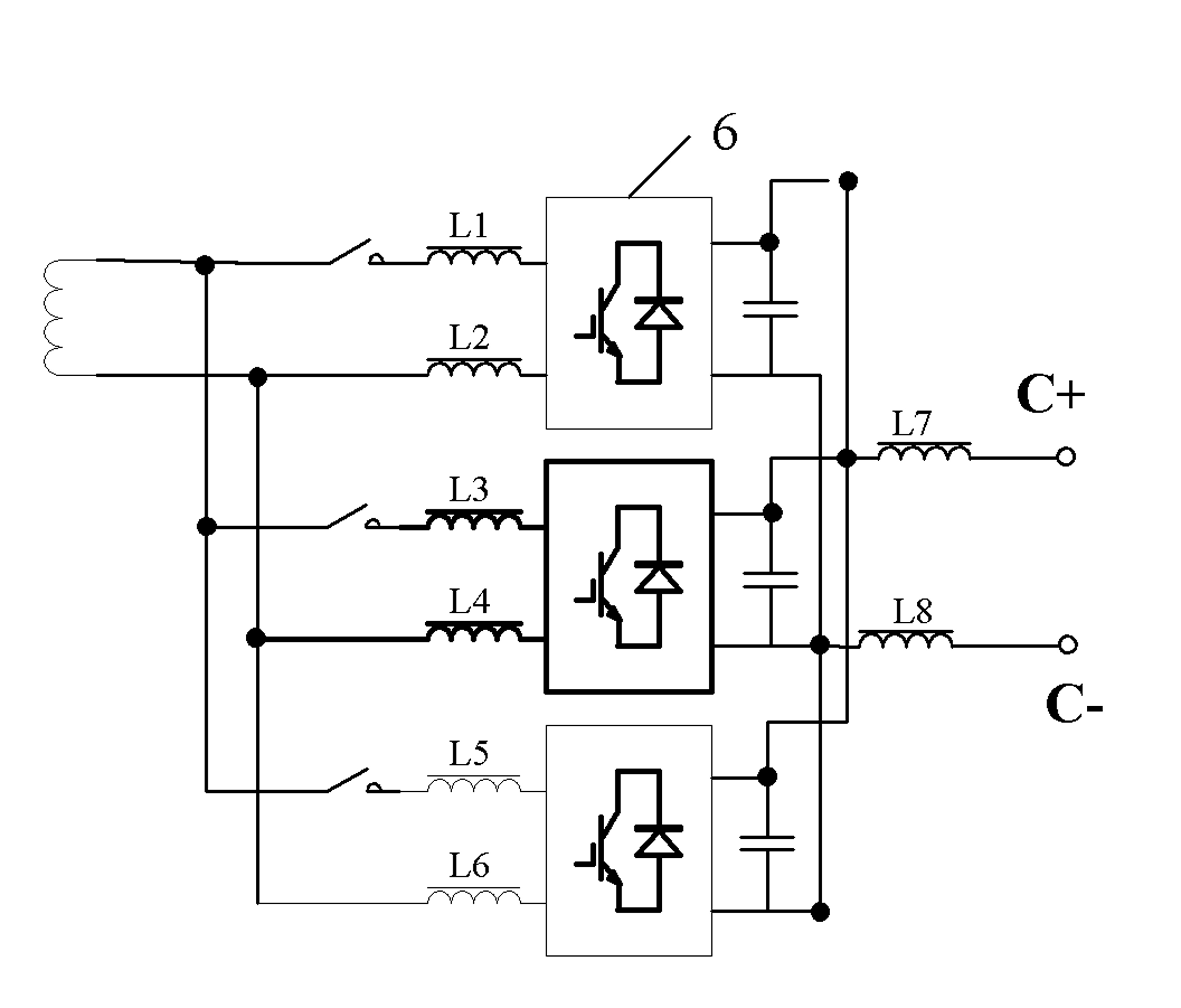

[0018] The main circuit of embodiment 1 is as Figure 5 As shown, it is assumed that the rated voltage of the same-phase power supply device is 27.5kV, and the rated capacity is 10MVA. The main circuit of the electrified railway in-phase power supply device is composed of four in-phase power supply units. Each in-phase power supply unit is composed of two 27.5kV double-winding isolation transformers (2, 5), supporting capacitor C, two sets of rectifier converters 3 and two sets of inverter converters 4; a single in-phase power supply unit is as described above . The whole device has eight sets of 27.5kV double-winding isolation transformers, eight sets of rectifier converters 3, four support capacitors C, and eight sets of inverter converters 4.

[0019] The structure and parameters of each transformer are consistent, the rated capacity is 1.25M, the secondary side is double winding, the voltage transformation ratio is 27.5kV / 0.5kV / 0.5kV, and the short-circuit impedance is 1...

Embodiment 2

[0024] The circuit of embodiment 2 is as Figure 4 As shown, the difference from Embodiment 1 is that there is only one in-phase power supply unit, and a three-winding transformer is used as the input and output multi-winding transformers, corresponding to three sets of rectifier converters 3 and three sets of inverter converters 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com