Method and equipment for treating and recycling reverse osmosis concentrated water and complex wastewater with high salt content

A reverse osmosis concentrated water and wastewater treatment technology, applied in the direction of osmosis/dialysis water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve pollution, low recovery rate of reverse osmosis system, Does not have problems such as COD removal effect, and achieves the effect of avoiding the tendency of silica scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

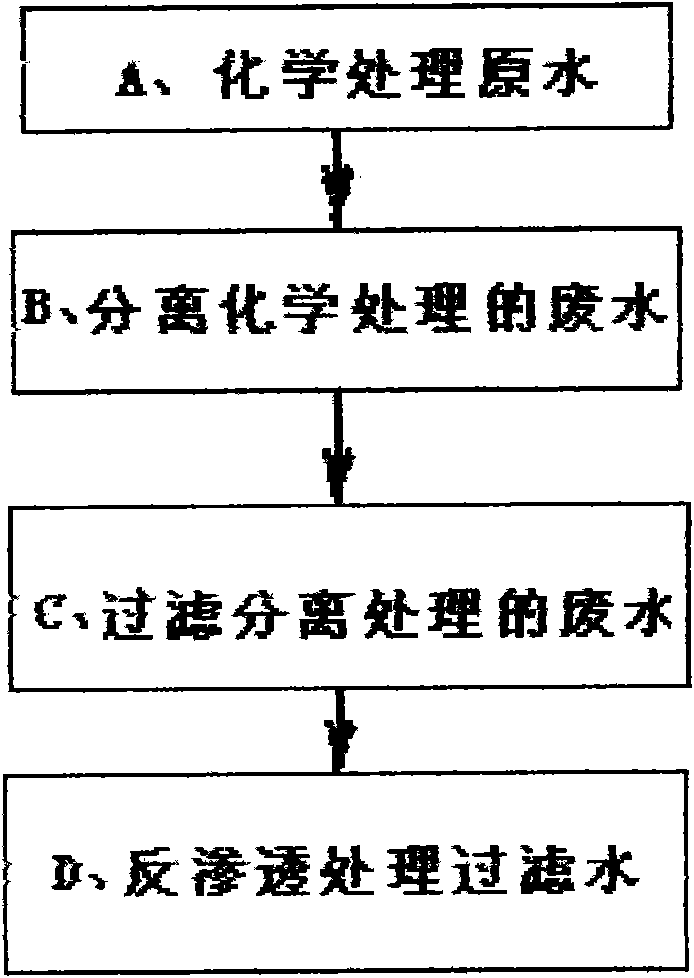

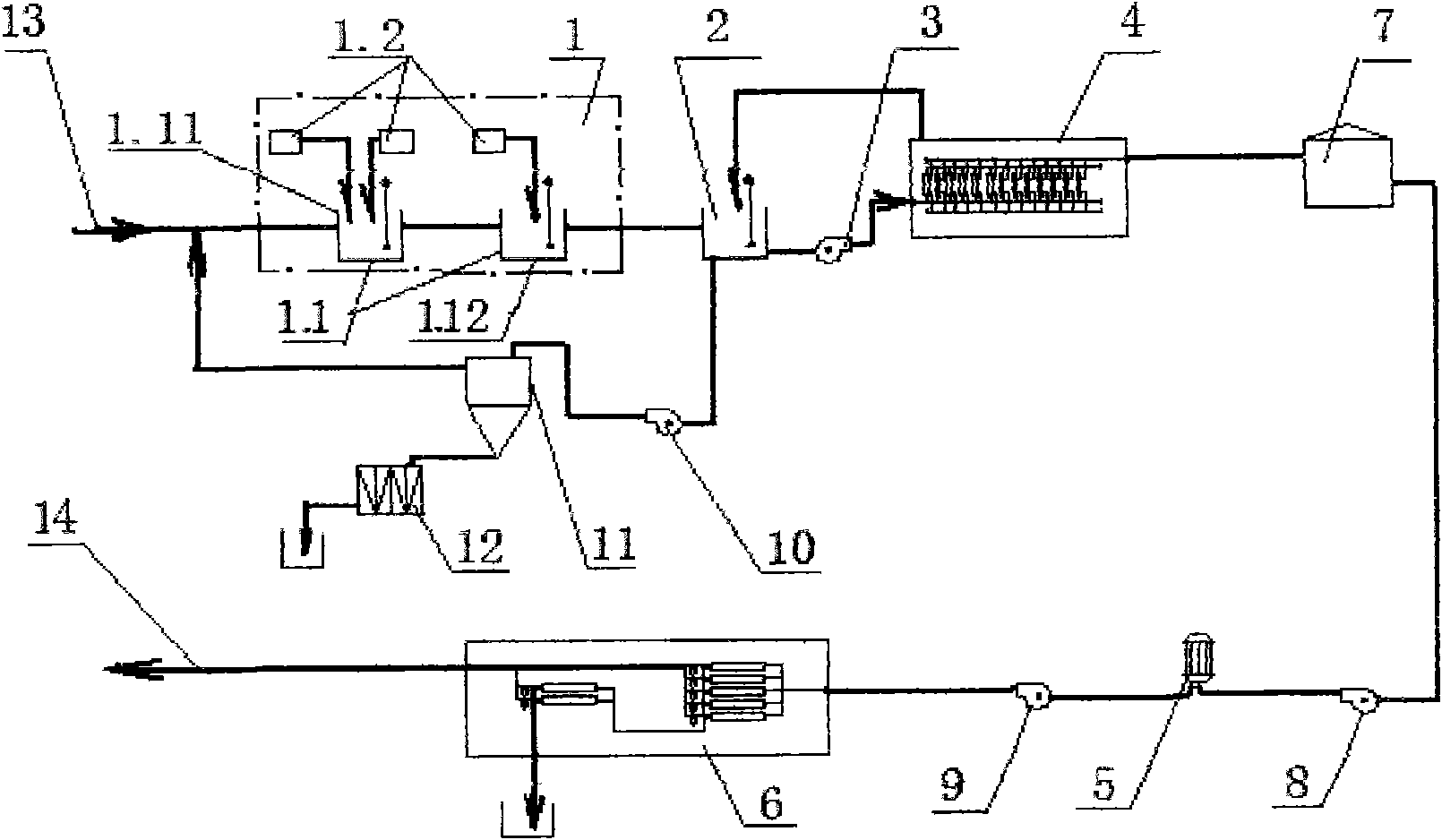

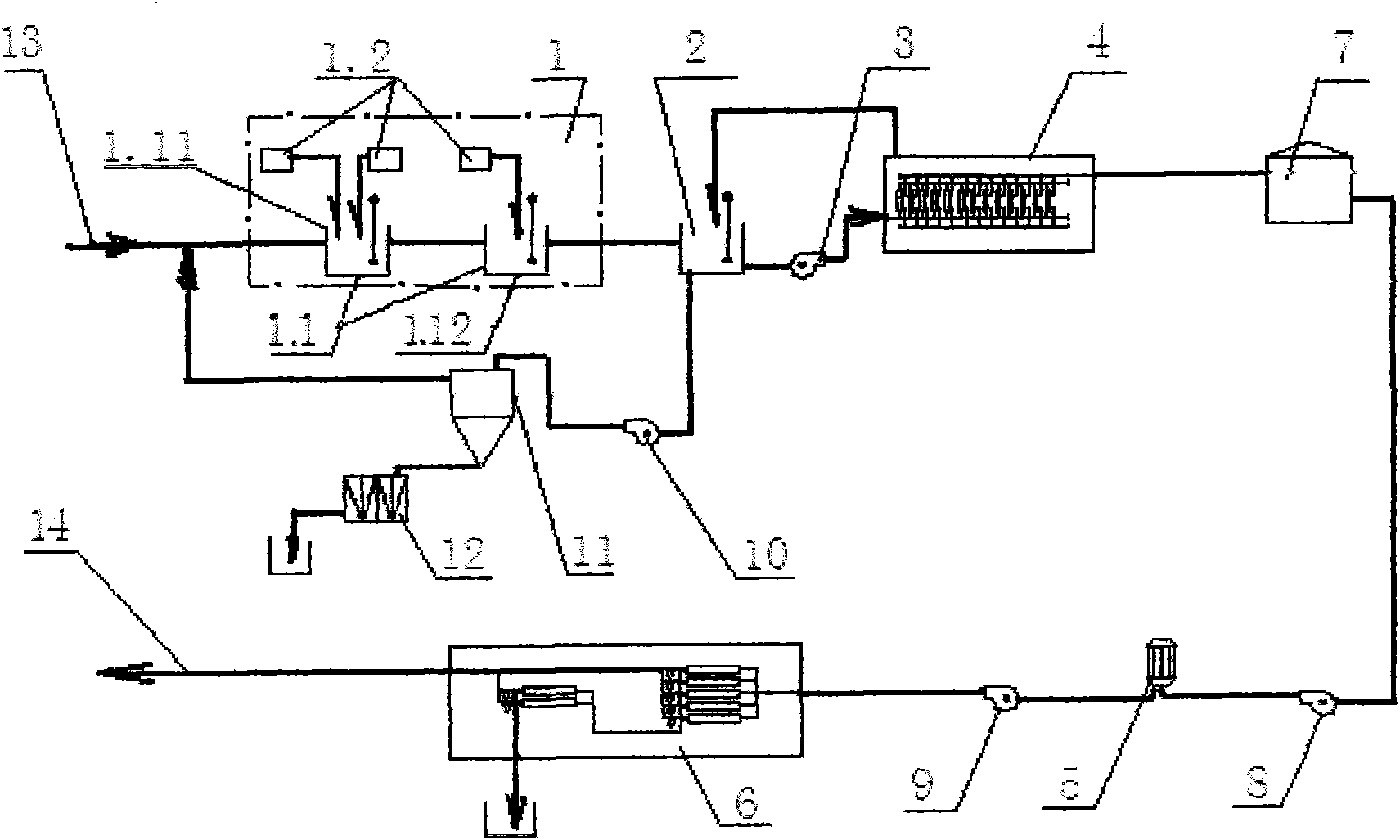

[0037] Such as figure 1 , 2 Shown, a kind of reverse osmosis concentrated water of the present invention and high salinity complex wastewater treatment and reuse method technical scheme are the following steps:

[0038] A. Chemical treatment of raw water: Inject reverse osmosis concentrated water and high-salt complex waste water, that is, raw water 13, into the reaction device 1 having a chemical reactor 1.1 and adding chemicals through a dosing device 1.2 to perform chemical treatment and increase the pH value , the reaction produces floc particles suspended in water and softens the raw water;

[0039] B. Separation of chemically treated waste water: inject the chemically treated waste water into the concentrator 2, then inject it into the separation host 4 through the booster pump 3 all the way, and discharge the other way to the muddy sewage treatment device; The floc particles are subjected to solid-liquid separation treatment, the separated floc particles are discharge...

Embodiment 2

[0045] Different from the above-mentioned embodiment 1, the chemical reactor 1.1 is a chemical reaction vessel, the solid content of the chemically treated wastewater at the inlet of the membrane separation host 4 is 0.02-10% by weight, and the flow rate at the inlet is 1-5%. m / s;

Embodiment 3

[0047] Different from the above-mentioned embodiment 1, the solid content of the chemically treated wastewater at the inlet of the membrane separation host 4 is 3-15% by weight, and the flow velocity at the inlet is 3-10 m / s;

[0048] 2. A kind of reverse osmosis concentrated water and high-salt-content complex wastewater treatment and recycling equipment of the present invention is further described as follows in conjunction with the accompanying drawings and examples:

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com