Beam limekiln

A technology of lime kiln and beam type, which is applied in the field of improvement of beam type lime kiln, can solve the problems of energy waste, increase of lime production cost, non-recyclability, etc., so as to improve economic benefits, reduce energy consumption and production cost, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

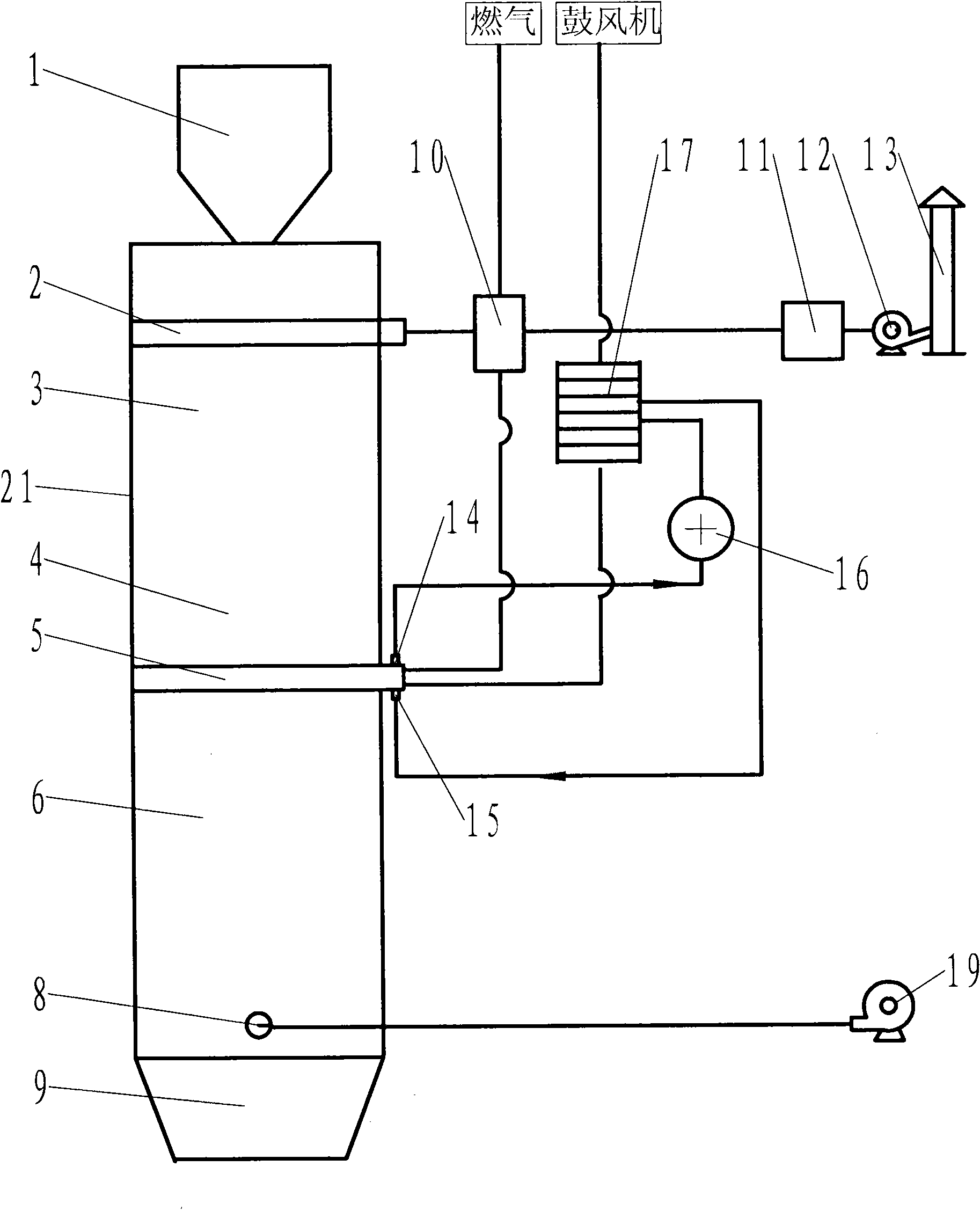

[0018] The beam type lime kiln of the present invention such as figure 1 As shown, it mainly includes a kiln body 21, a feeding system, a combustion system, a discharging system, an air supply system and a control system. The kiln body includes a feed inlet, a preheating zone 3, a calcining zone 4, a cooling zone 6 and a discharge port. Two suction beams 2 are arranged on the upper part of the preheating zone. The calcining belt 4 is equipped with upper and lower two-layer combustion beams 5, the upper layer is provided with 3 combustion beams 5, and the lower layer is provided with 2 combustion beams, and the combustion beams are "T" type combustion beams. The beam body is provided with a fuel pipeline and an air channel, both of which are box-shaped, and the fuel pipeline passes through the air channel. The fuel pipeline is connected to the burners, which are gas fuel burners, and the burners are arranged on both sides of the combustion beam, with 10 burners on each side. ...

Embodiment 2

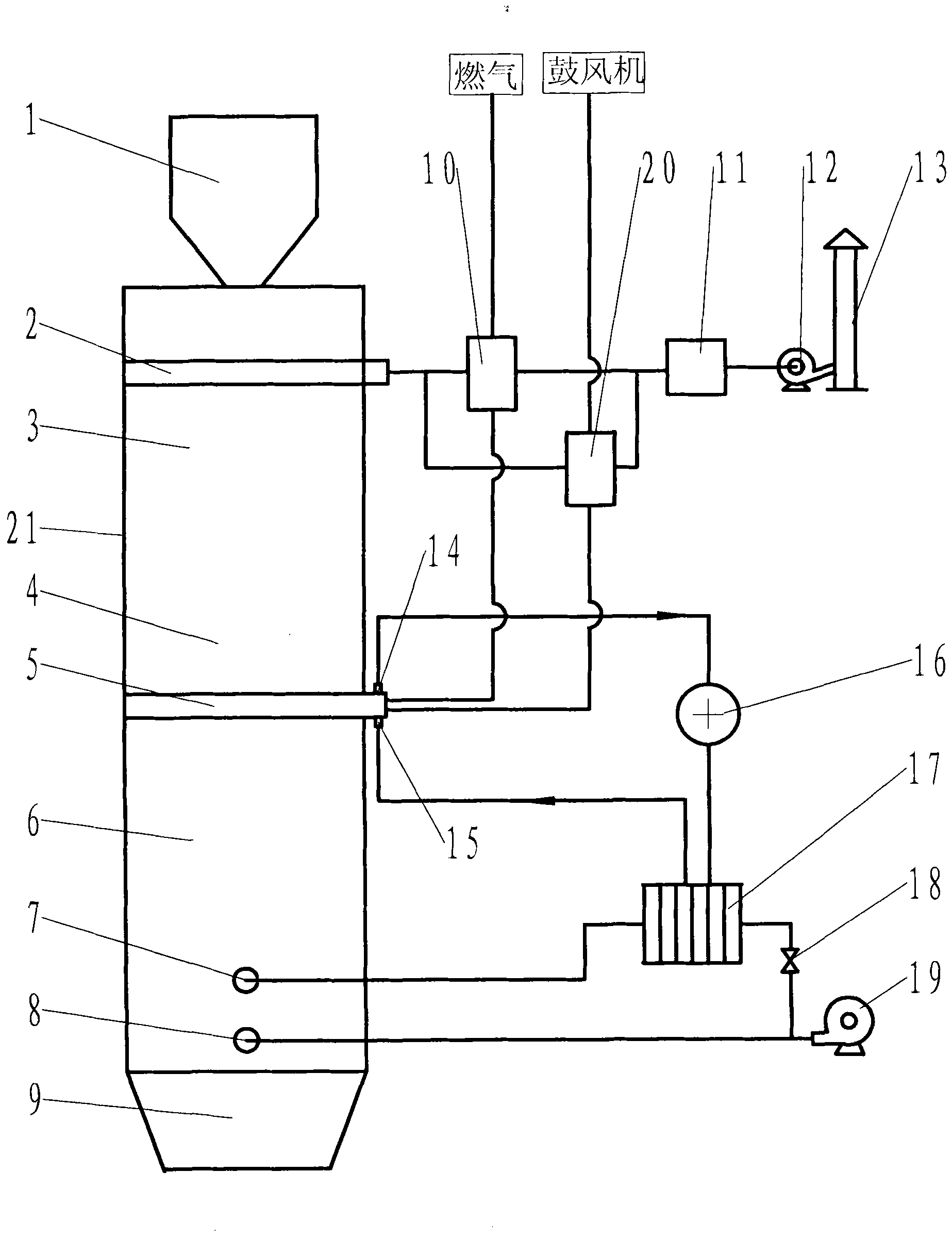

[0021] Another embodiment of the present invention is as figure 2 As mentioned above, the cooling zone of the beam type lime kiln is provided with two cooling air inlets, namely the cooling air inlet 8 and the upper cooling air inlet 7 . The cooling fan 19 is divided into two paths, one path is connected to the cooling air inlet 8, and the other path is connected to the upper cooling air inlet 7 through the heat transfer oil cooler. The connecting pipeline is provided with a valve 18 for adjusting the air volume entering the heat transfer oil cooler. The outlet of the upper suction beam 2 is divided into two paths, one path is connected to the exhaust gas discharge system through the flue gas / gas heat exchanger 10, and the other path is connected to the exhaust gas emission system through the flue gas / air heat exchanger. In this embodiment, the heat transfer oil is used to exchange heat with the cooling air entering the cooling zone, and the heat is brought into the kiln bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com