Preparation method of 8-hydroxyquinoline zinc with shape of octahedron

A technology of hydroxyquinoline zinc and hydroxyquinoline, applied in the field of preparation of octahedral shape 8-hydroxyquinoline zinc, to achieve the effect of easy to obtain raw materials, simple raw materials and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The object of the present invention is to provide a kind of preparation method of octahedral morphology 8-hydroxyquinoline zinc, and its concrete steps comprise: (1) 8-hydroxyquinoline powder is dissolved in ethylene glycol, obtains 8-hydroxyquinoline The concentration is the solution A of 145 mg / ml; (2) zinc acetate dihydrate is dissolved in ethylene glycol, and the concentration scope that obtains zinc acetate dihydrate is solution B between 110 mg / ml to 220 mg / ml; (3) After mixing solution A and solution B, move it into a stainless steel reaction kettle with a polytetrafluoroethylene substrate; (4) react at a temperature of 160°C to 190°C for 12 to 48 hours; (4) after the reaction, The product was separated by centrifugation, the precipitate was washed successively with distilled water and ethanol, and the obtained precipitate was dried under vacuum to obtain light yellow 8-hydroxyquinoline zinc powder.

[0013] The median diameter (D50) of the prepared octahedral 8-...

Embodiment 1

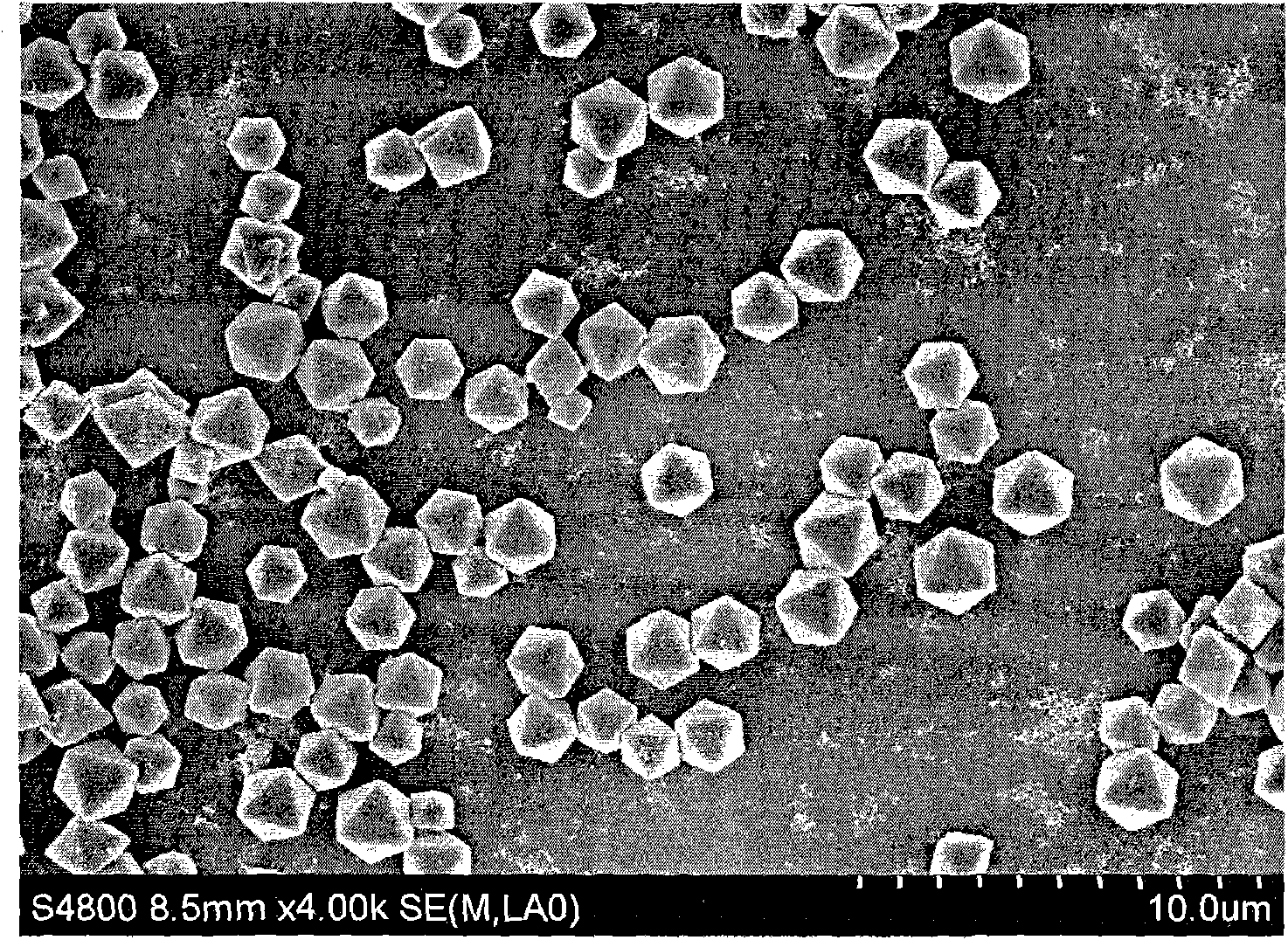

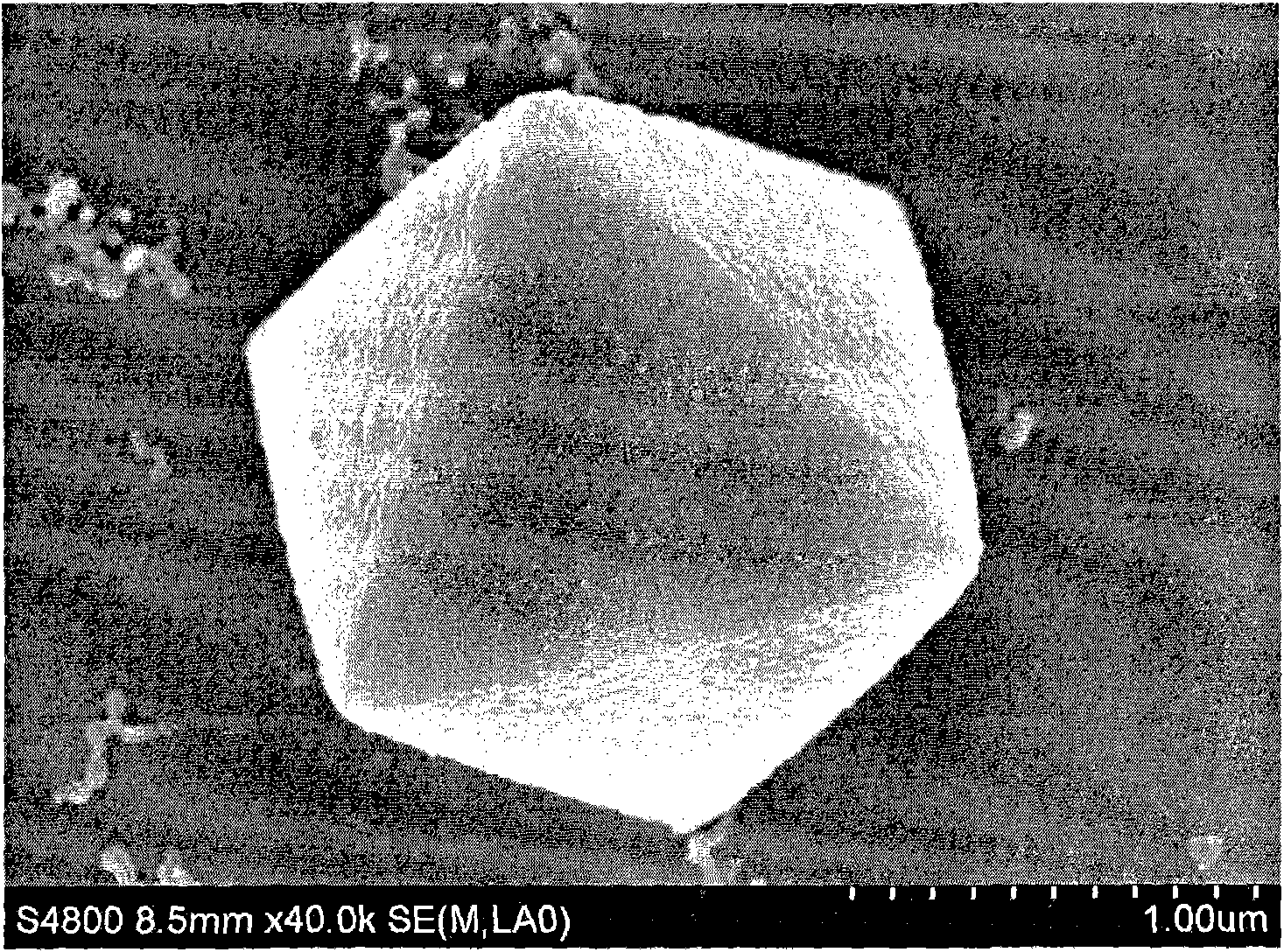

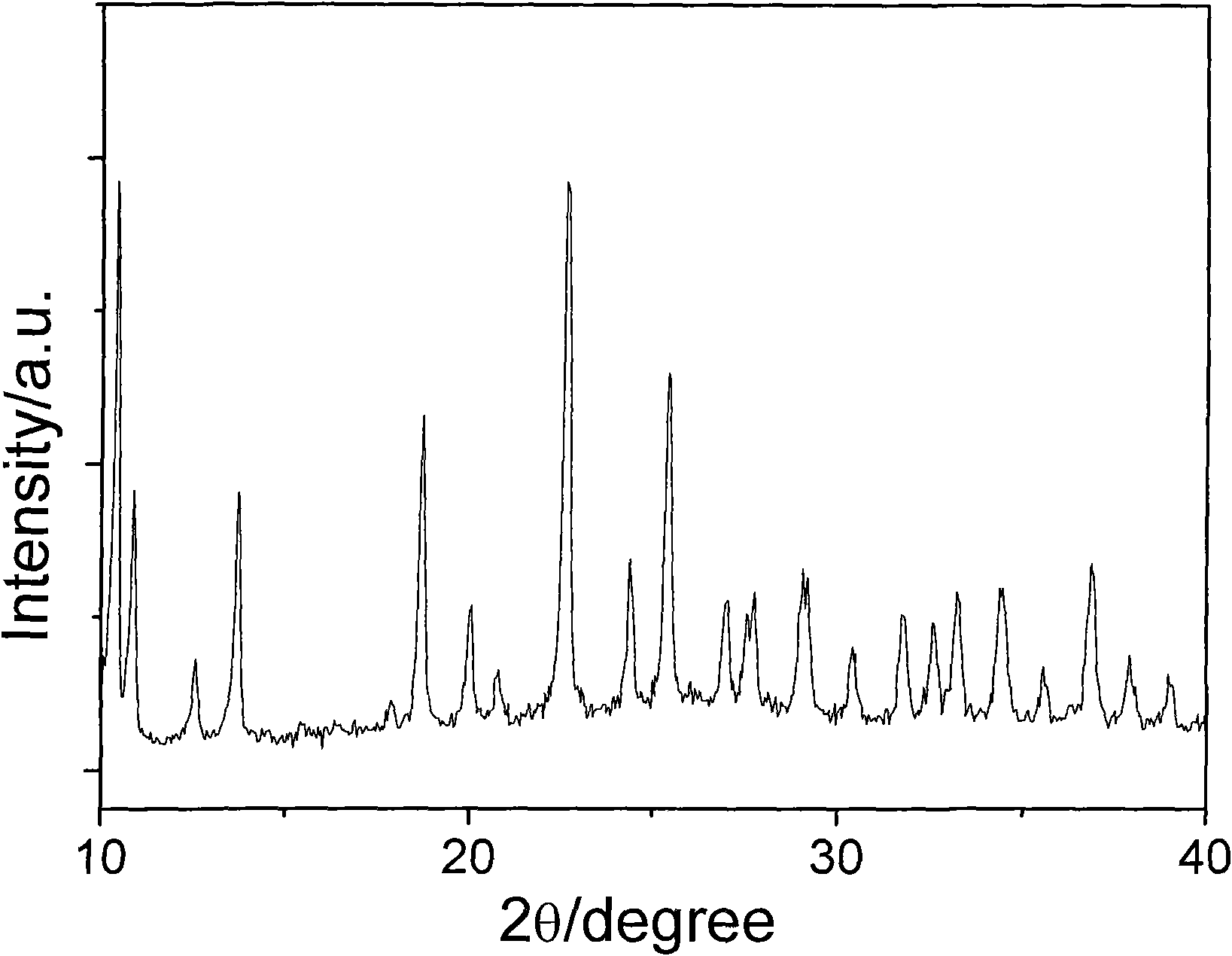

[0016] Dissolve 1mmol of 8-hydroxyquinoline in 20mL of ethylene glycol, and 1mmol of zinc acetate dihydrate in 20mL of ethylene glycol. After mixing the above two solutions, move them into a stainless steel reactor with a polytetrafluoroethylene substrate, and then raise the temperature To 180 ℃ and constant temperature reaction for 24h. After the reaction, the product was centrifuged, the precipitate was washed with distilled water and ethanol in sequence, and the obtained precipitate was dried under vacuum to obtain a light yellow powder, that is, to obtain 8-hydroxyquinoline with a median diameter of about 1 μm and an octahedral shape. zinc. see figure 1 and figure 2 Octahedral morphology Znq prepared in the first embodiment 2 scanning electron microscope photographs. see image 3 Octahedral morphology Znq prepared in the first embodiment 2 The XRD pattern of image 3 It can be seen that 8-hydroxyquinoline zinc is a hexagonal crystal phase, and no heterophase peak i...

Embodiment 2

[0018] Dissolve 1mmol of 8-hydroxyquinoline in 20mL of ethylene glycol, and 0.5mmol of zinc acetate dihydrate in 20mL of ethylene glycol. After mixing the above two solutions, move them into a stainless steel reactor with a polytetrafluoroethylene substrate, and then The temperature was raised to 180°C and the reaction was carried out at a constant temperature for 24h. The other preparation conditions were the same as in Example 1, and 8-hydroxyquinoline zinc with a median diameter of about 0.2 μm in octahedral shape was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com