Sealing device for biomass gasification furnace

A technology of sealing device and gasification furnace, which is applied in the direction of household stove/stove, manufacture of combustible gas, gaseous heating fuel, etc. It can solve the problems of polluting the furnace environment, strong smell, water is easily polluted by tar, etc., to increase costs, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

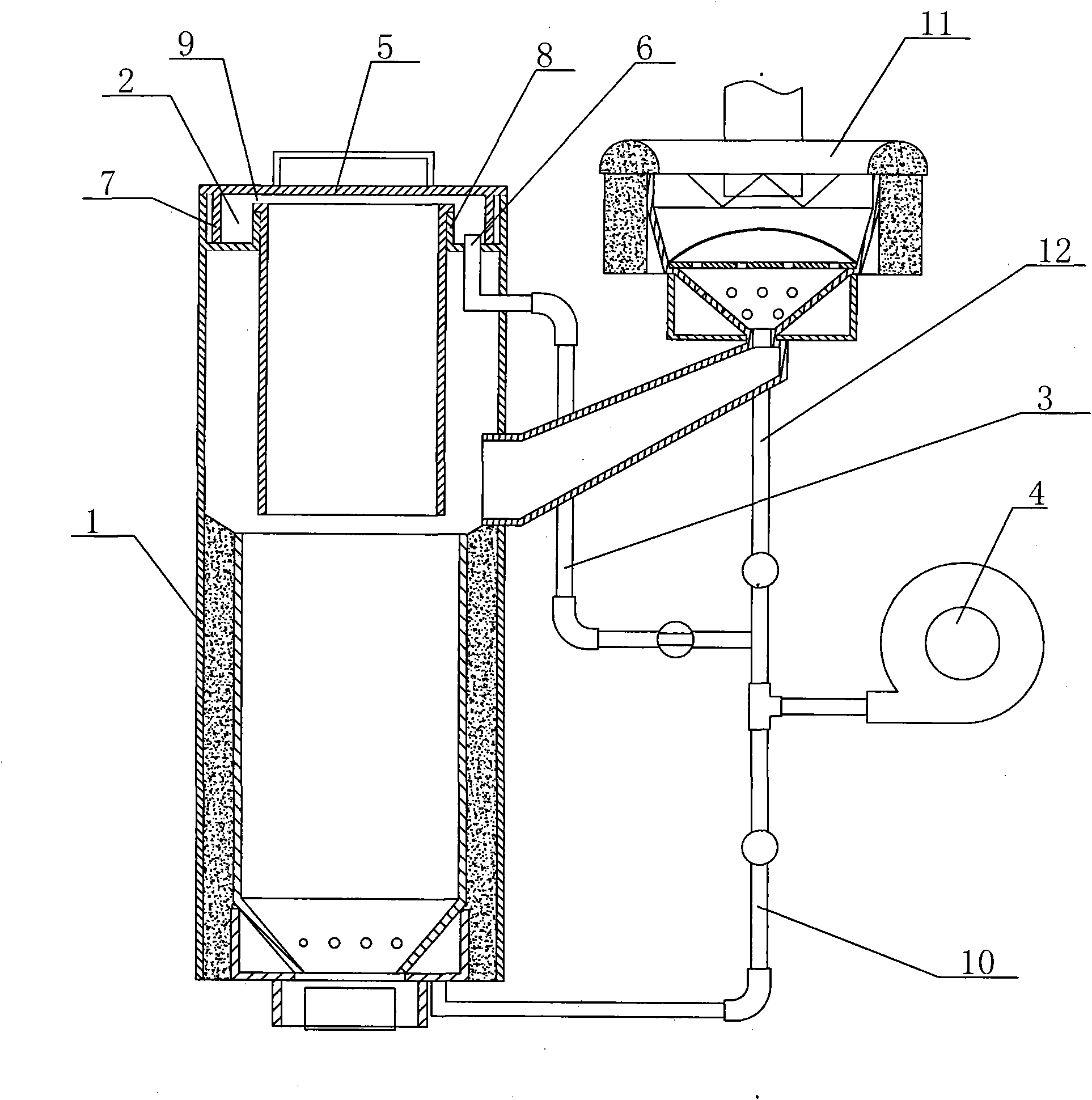

[0020] Such as figure 1 As shown, an annular sealing groove 2 is arranged inside the top of the furnace body 1, and the bottom of the sealing groove 2 communicates with the blower 4 through the air inlet pipe 3. When the furnace cover 5 is covered, the air inlet 6 of the sealing groove 2 is located in the furnace Inside the outer edge 7 of the cover, there is an air inlet channel 9 between the top of the furnace cover 5 and the top of the inner ring 8 of the sealing groove 2 . In this embodiment, the air inlet pipe 3 , the supply pipe 10 entering the furnace bottom and the oxygen distribution pipe 12 entering the stove body 11 are all in communication with the blower 4 .

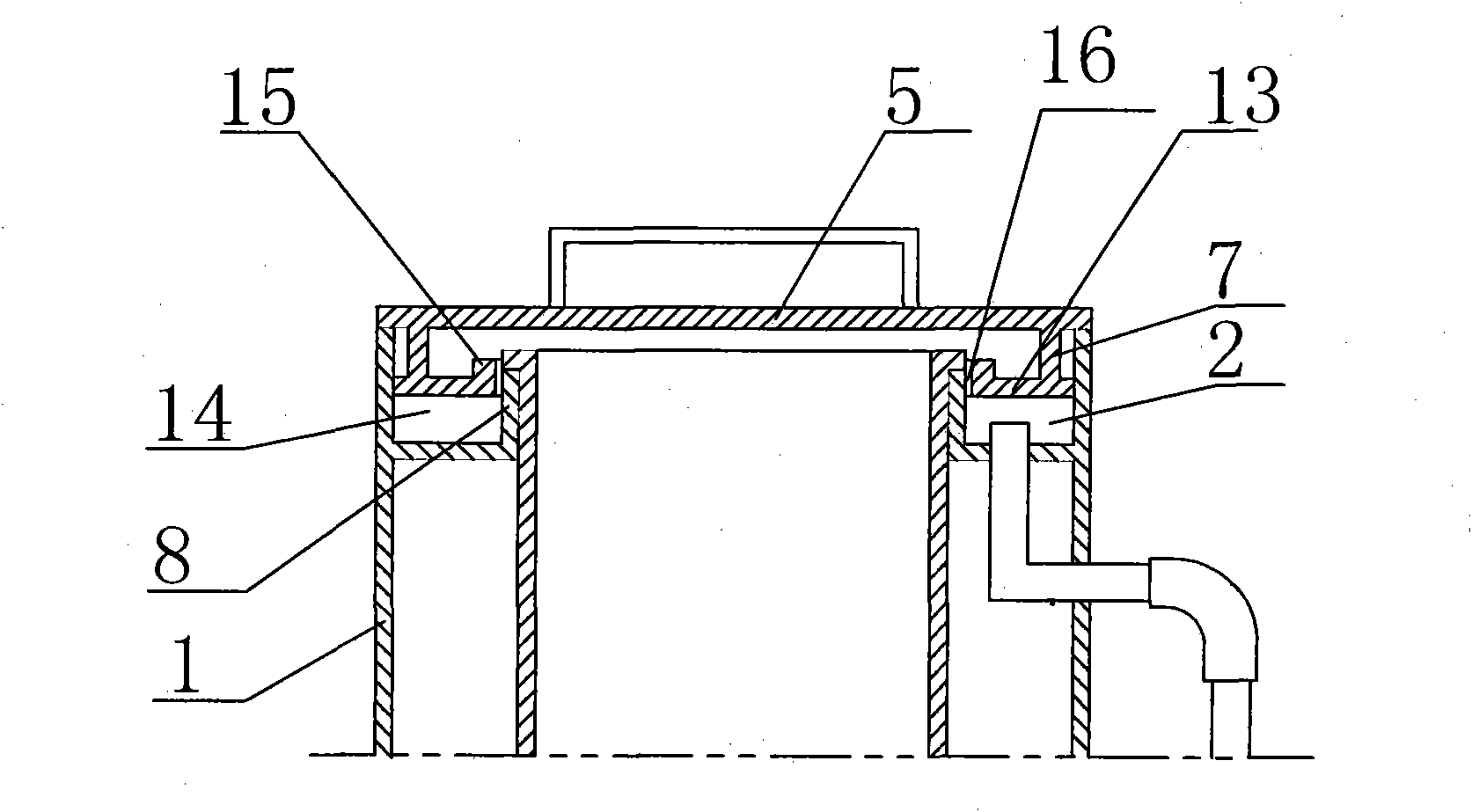

[0021] Such as figure 2 As shown, an annular gasket 13 is arranged in the sealing groove 2, and the annular gasket 13 forms an air inlet chamber 14 with the bottom and both sides of the sealing groove 2. Air intake gaps 16 are formed between the inner rings 8 of the inner rings.

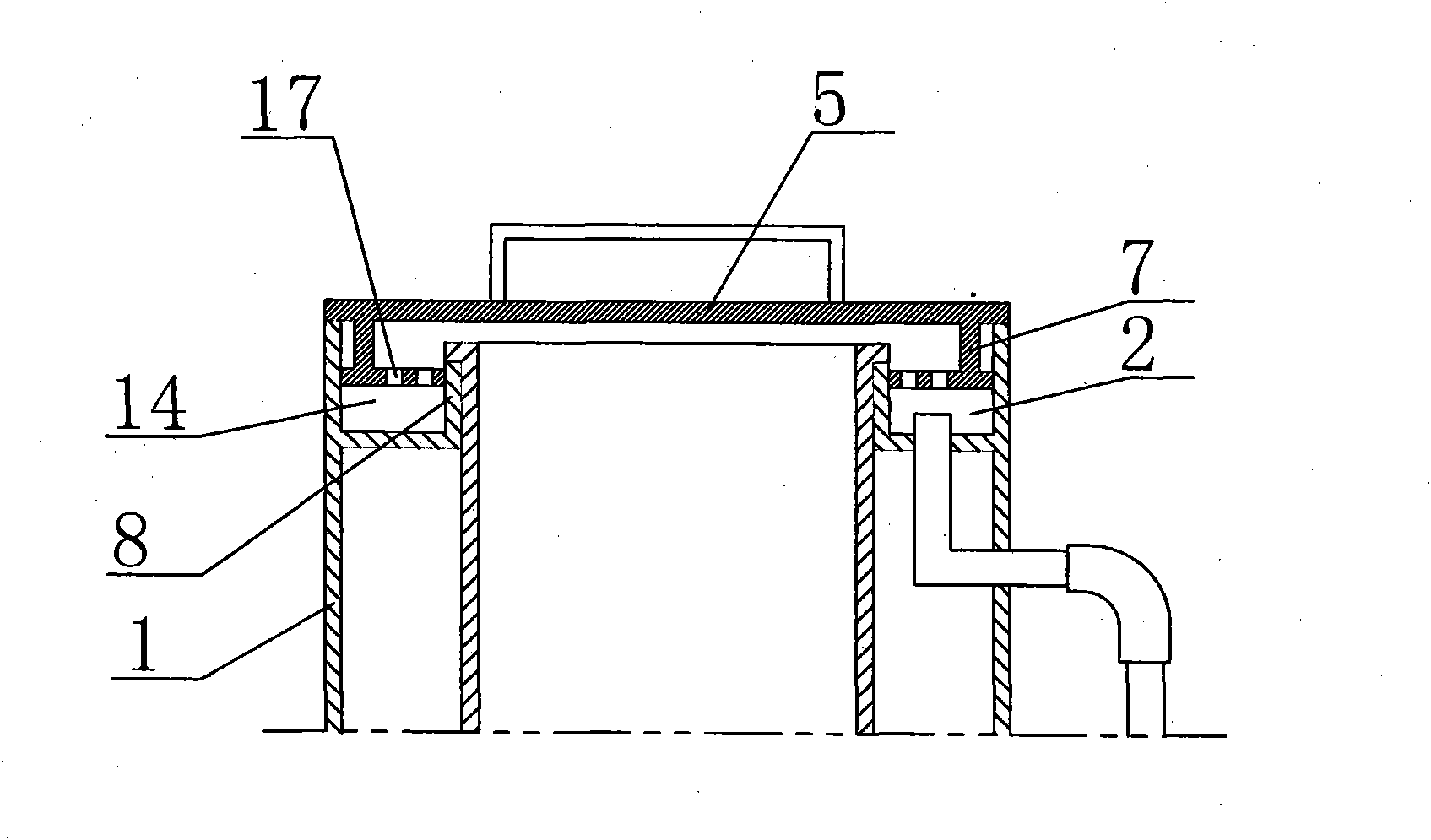

[0022] Such as image ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap