Solid-state light source assembling device and method

A solid-state light source and assembly device technology, applied in the direction of light source, electric light source, electric light source, etc., can solve the problems of shortened service life, light attenuation, LED and metal plate cannot be tightly bonded, etc., to achieve the best assembly yield, the best Effects of Luminous Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

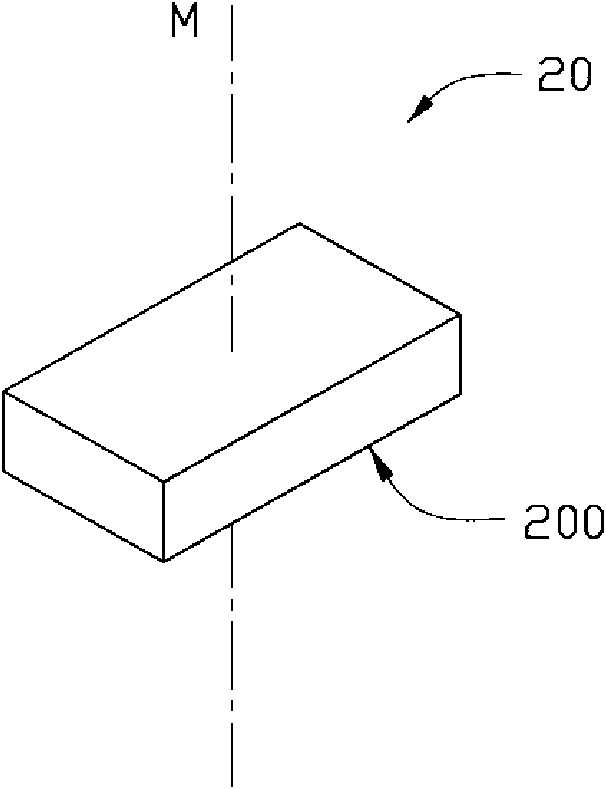

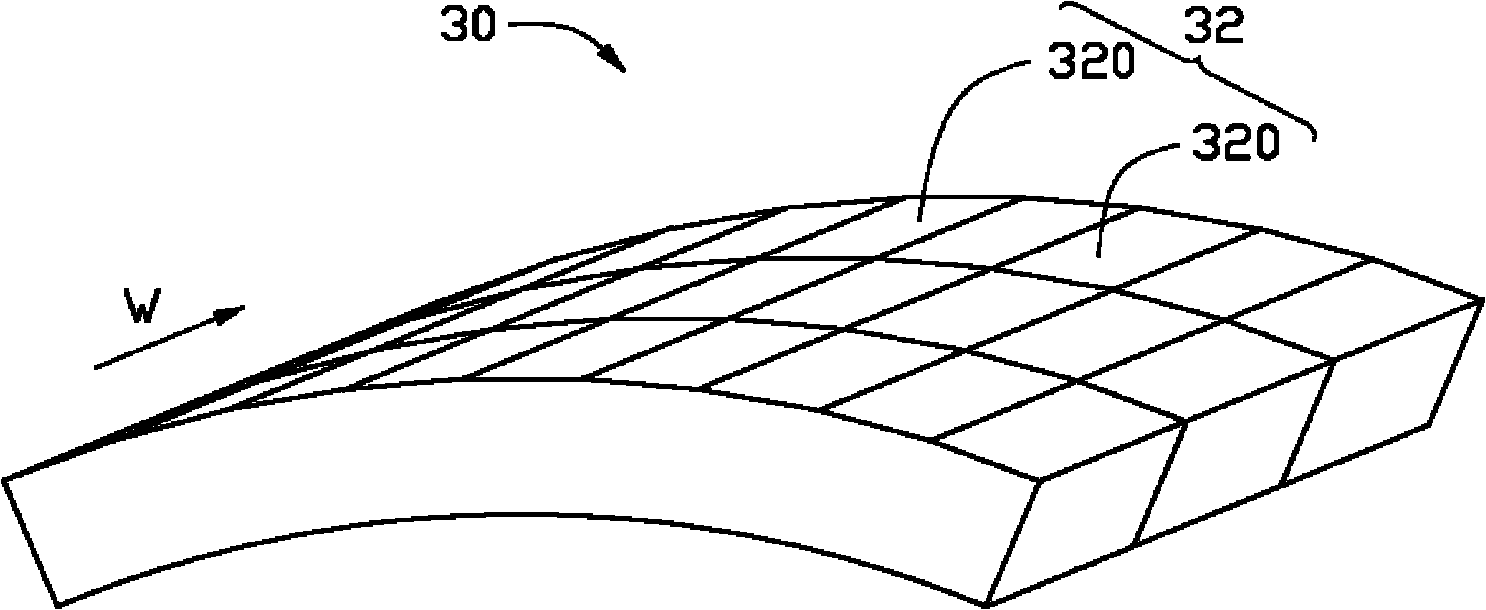

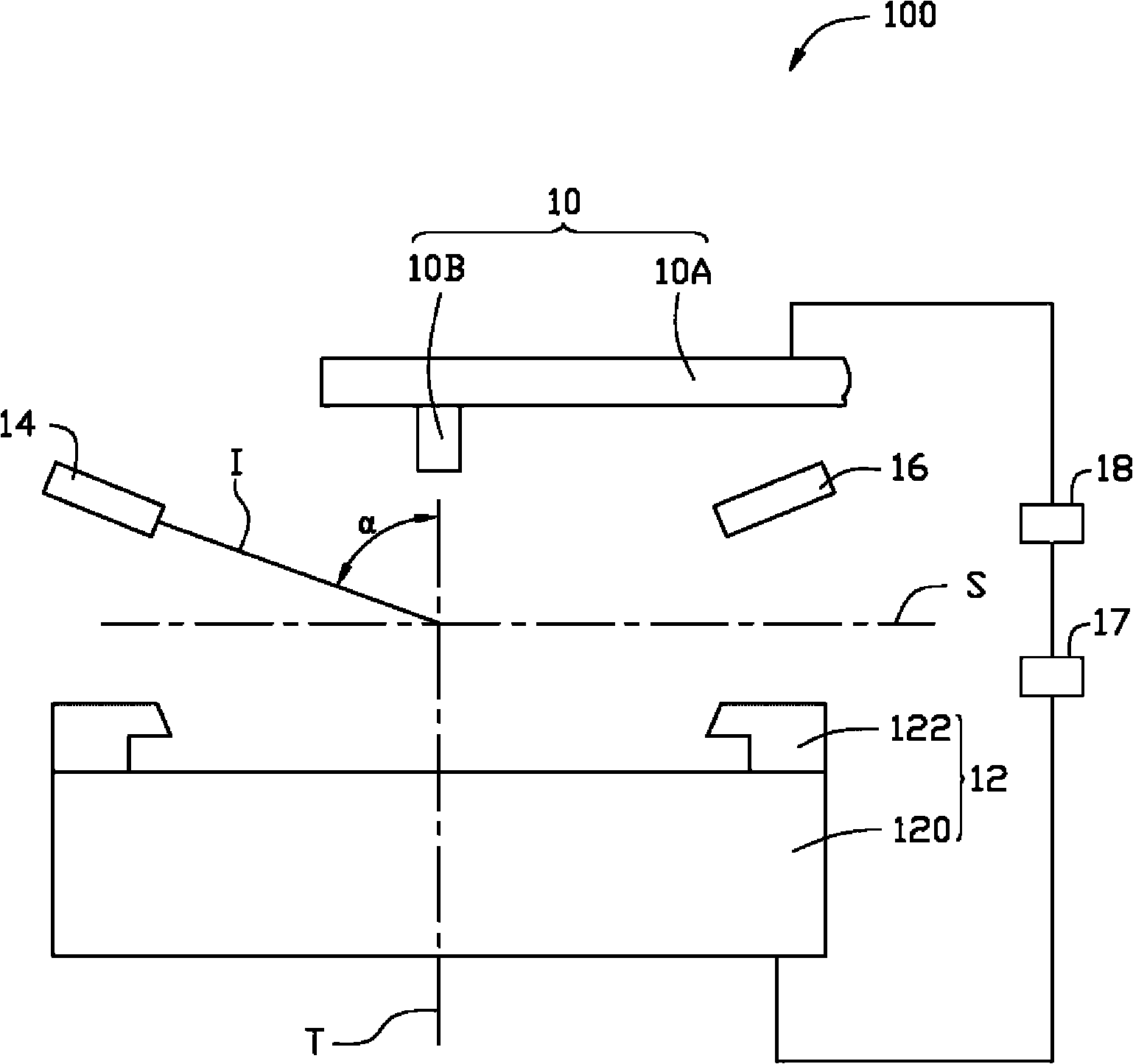

[0016] Please refer to Figure 1 to Figure 3 , a solid-state light source assembling device 100 provided in the first embodiment of the present invention is used for attaching a solid-state light source 20 on a carrier 30 to assemble the solid-state light source 20 and the carrier 30 . The solid-state light source 20 can be an LED chip or an LED, such as figure 1 As shown, in this embodiment, the solid-state light source 20 is an LED chip 20 with a cuboid outline, and the LED chip 20 has a mounting surface 200 and a central axis M, wherein the central axis M is perpendicular to the mounting surface 200 And located on the geometric center of the LED chip. Such as figure 2 As shown, the carrier 30 can be made of metal, which has an arc profile extending along a predetermined direction W as a whole, and includes a mounting surface 32 for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com