Optical imaging lens

An optical imaging lens and lens technology, applied in the field of optical imaging, can solve problems affecting the quality of optical imaging, inaccurate assembly, eccentricity of optical imaging lens, etc., and achieve the effect of good optical imaging quality and good assembly yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

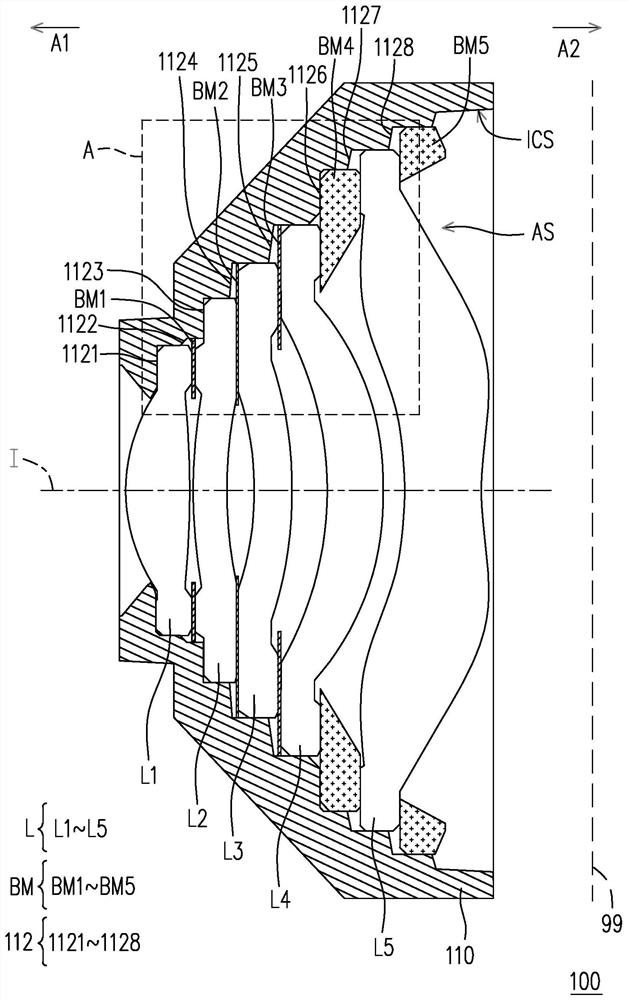

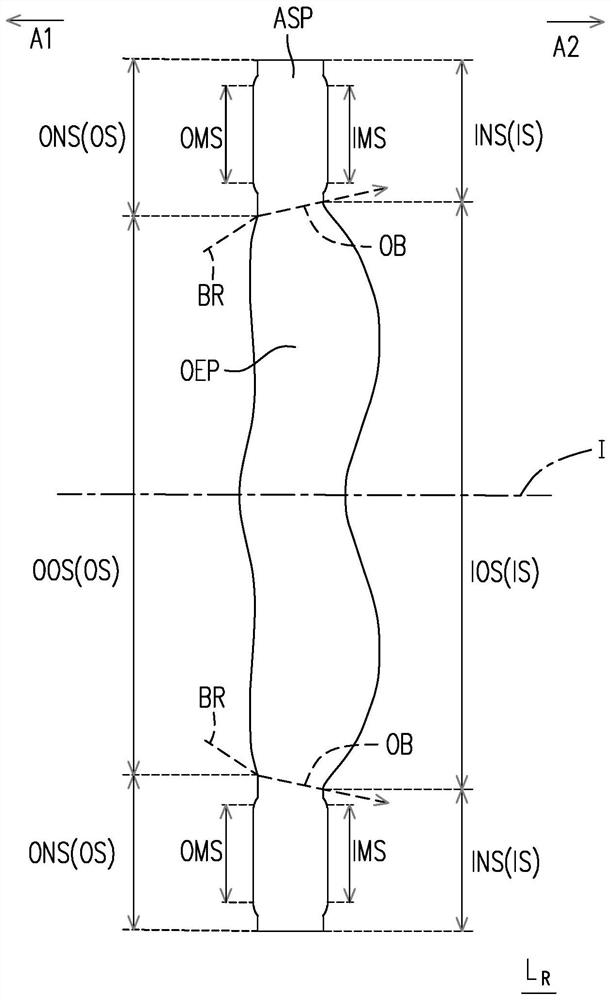

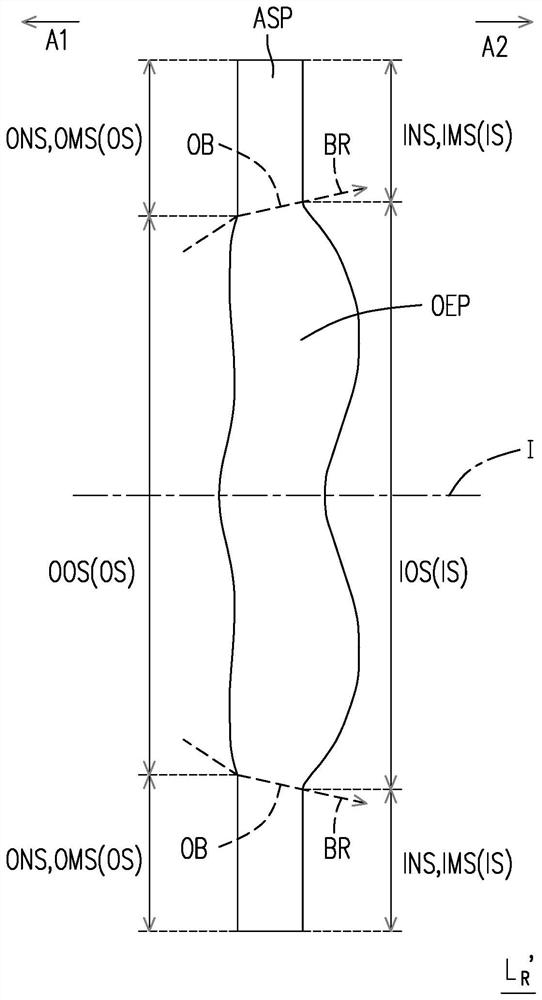

[0035] Before starting to describe the present invention in detail, first clearly indicate the symbols in the drawings: 100, 100a: optical imaging lens; 110, 110a: lens barrel; 112, 1121-1129: installation part; 99: imaging surface; A, B , C, E, F, G: area; A1: object side; A2: image side; AS: installation space; ASP: assembly department; BM, BM', BM1~BM5, BM1'~BM9': shading element; BR : imaging light; CF1, CF2, CF1', CF2': chamfering; d, D, d', D': clearance; D1, D2, RA1~RA4: vertical distance; F1~F6: bearing force; H: Direction; I: optical axis; ICS: inner peripheral surface; IOS: image side optical surface; INS: image side optical ineffective surface; IMS, IMS1~IMS6: image side mechanical surface; L, L1~L6: lens; L R , L R ': reference lens; OEP: optically effective part; OS: object side; OOS, OOS1: object-side optically effective surface; ONS: object-side optically inactive surface; OMS, OMS1~OMS6: object-side mechanical surface; P1, P2: fulcrum ;S1, S2, S1', S2': recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com