Light-emitting semiconductor connection structure and method thereof

A technology of light-emitting semiconductors and connection methods, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of unfavorable use of high-power light-emitting diodes, increased production costs, and low production efficiency, achieving strong bonding, increased production capacity, and reliable The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

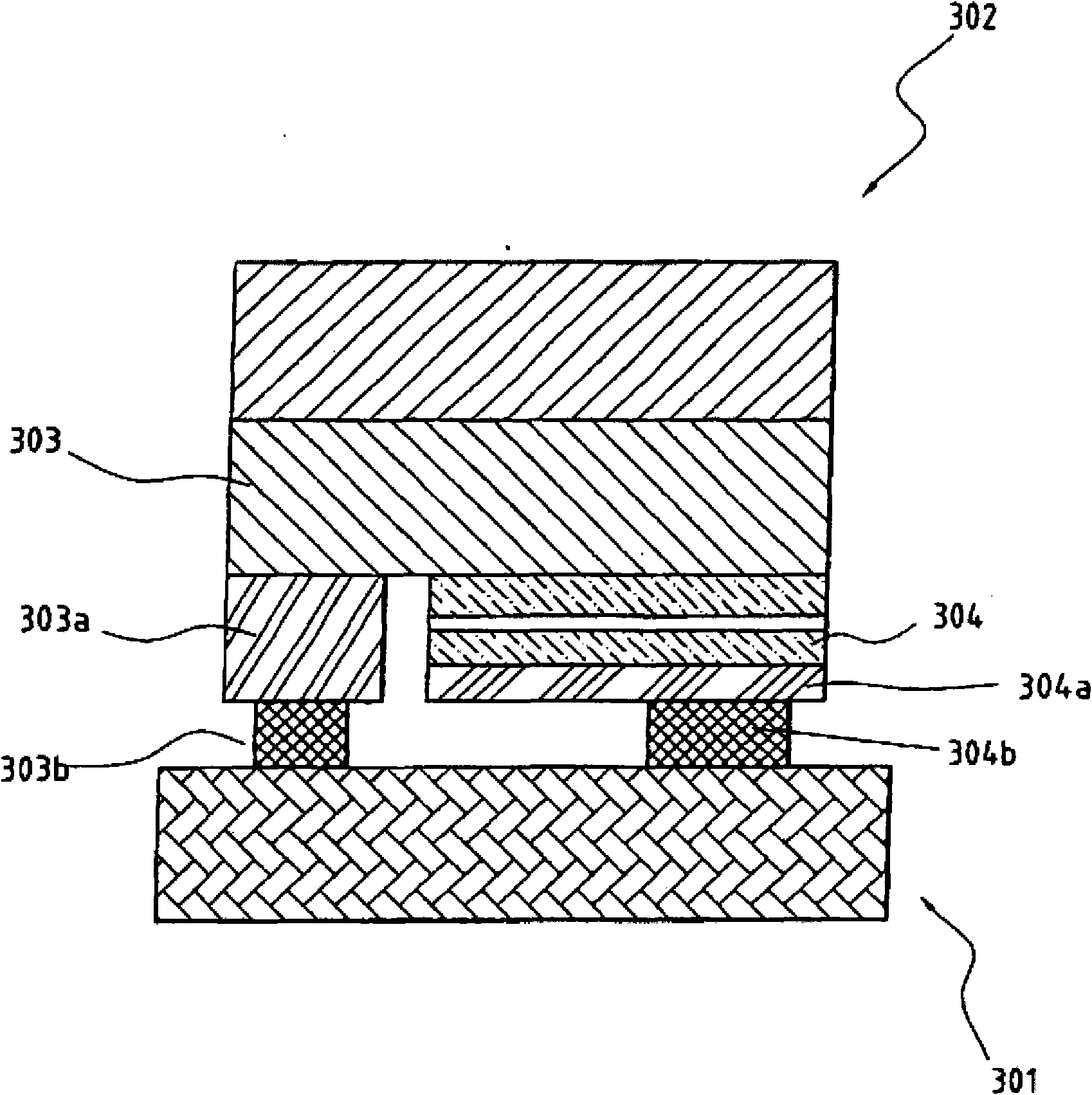

[0021] The preferred embodiments of the present invention will be further described in detail below with reference to the accompanying drawings. The ratio of certain dimensions relative to other parts is exaggerated to provide a clearer description and help those skilled in the art to understand the present invention.

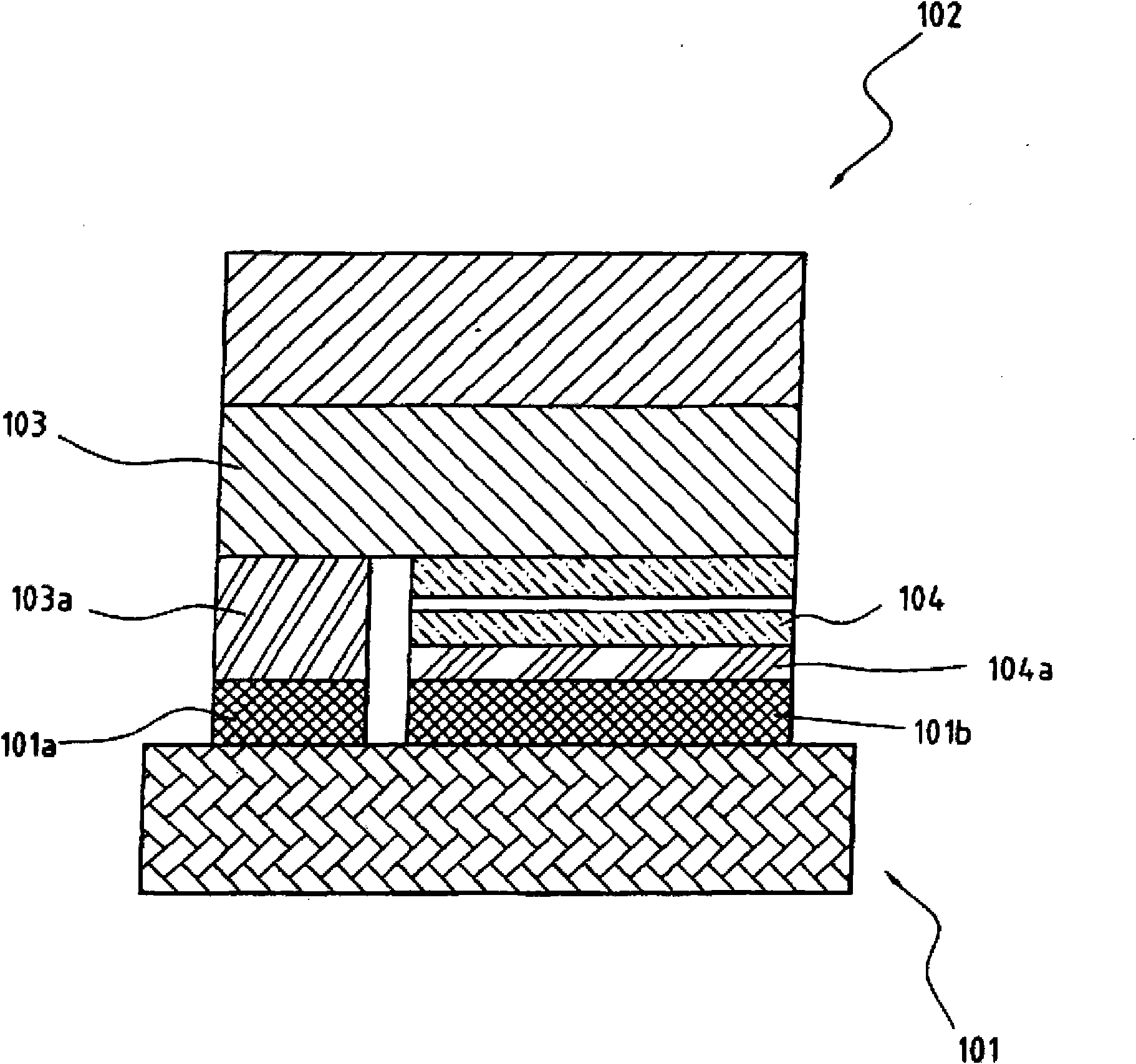

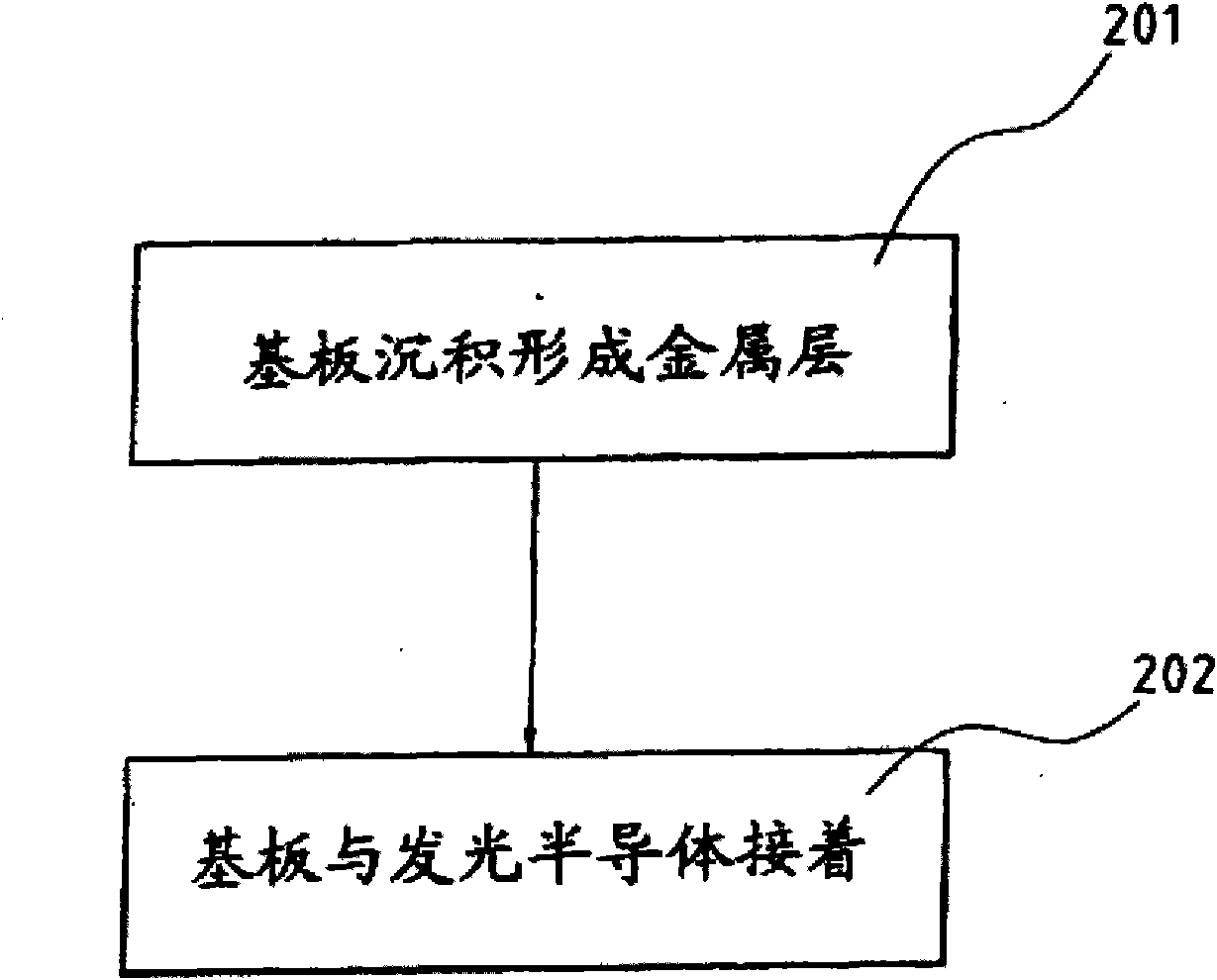

[0022] figure 1 Shown is a schematic cross-sectional view of a preferred embodiment of the light-emitting semiconductor connection structure and method thereof of the present invention; figure 2 shown as the invention figure 1 Preferred embodiment method flowchart.

[0023] refer to figure 1 As shown, the first embodiment of the light emitting semiconductor connection structure of the present invention is mainly a structure in which a light emitting semiconductor 102 is connected through a substrate 101 .

[0024] Wherein, the substrate 101 is a structure with electrical circuits, and at least a first metal layer 101a and a second metal layer 101b are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com