Method for improving electrochemical performance of positive material LiNi0.5Mn1.5O4 of lithium ion battery

A technology of lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as health hazards and chromium environmental pollution, and achieve the effects of reducing human health hazards, reducing environmental pollution, and avoiding shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

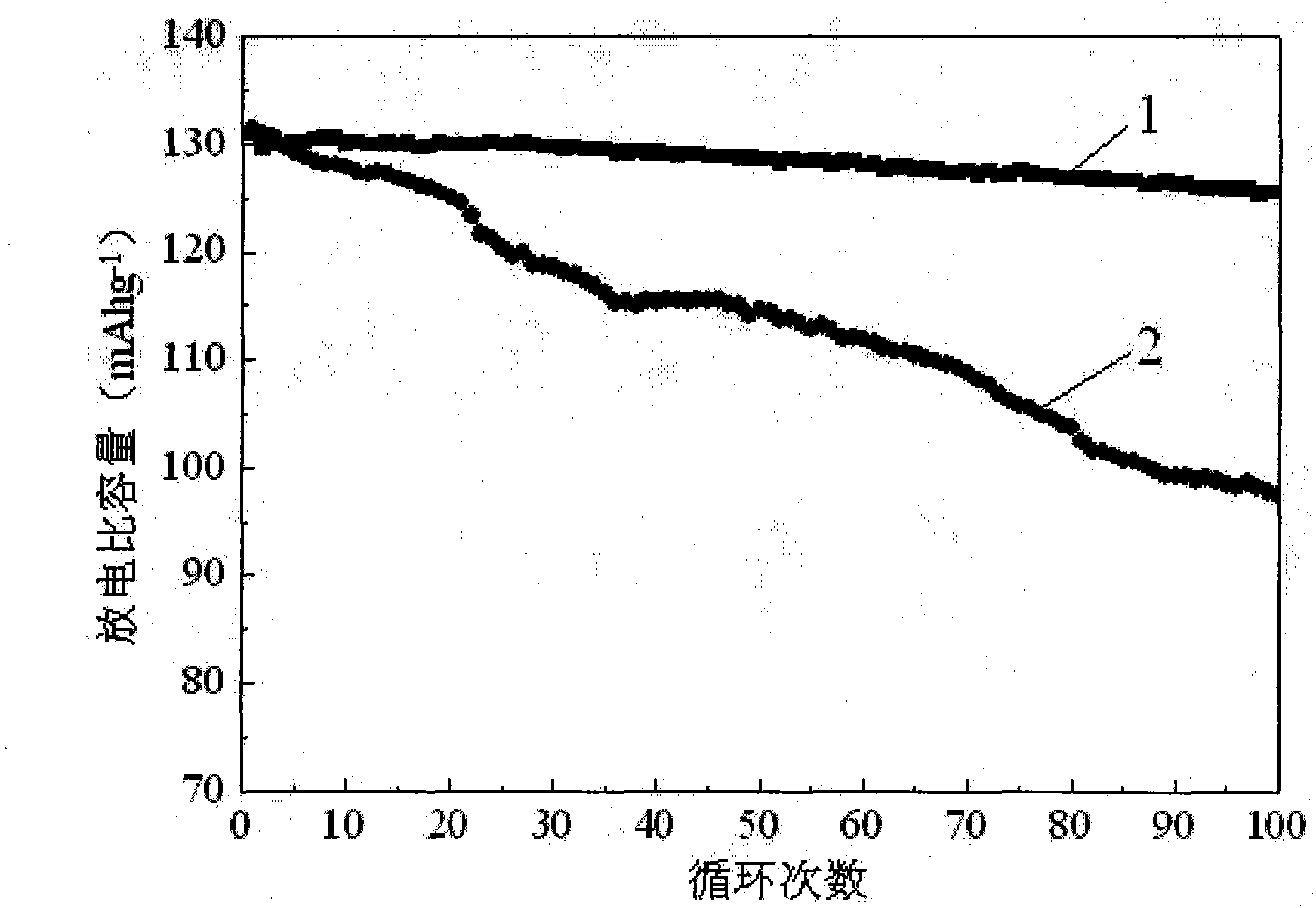

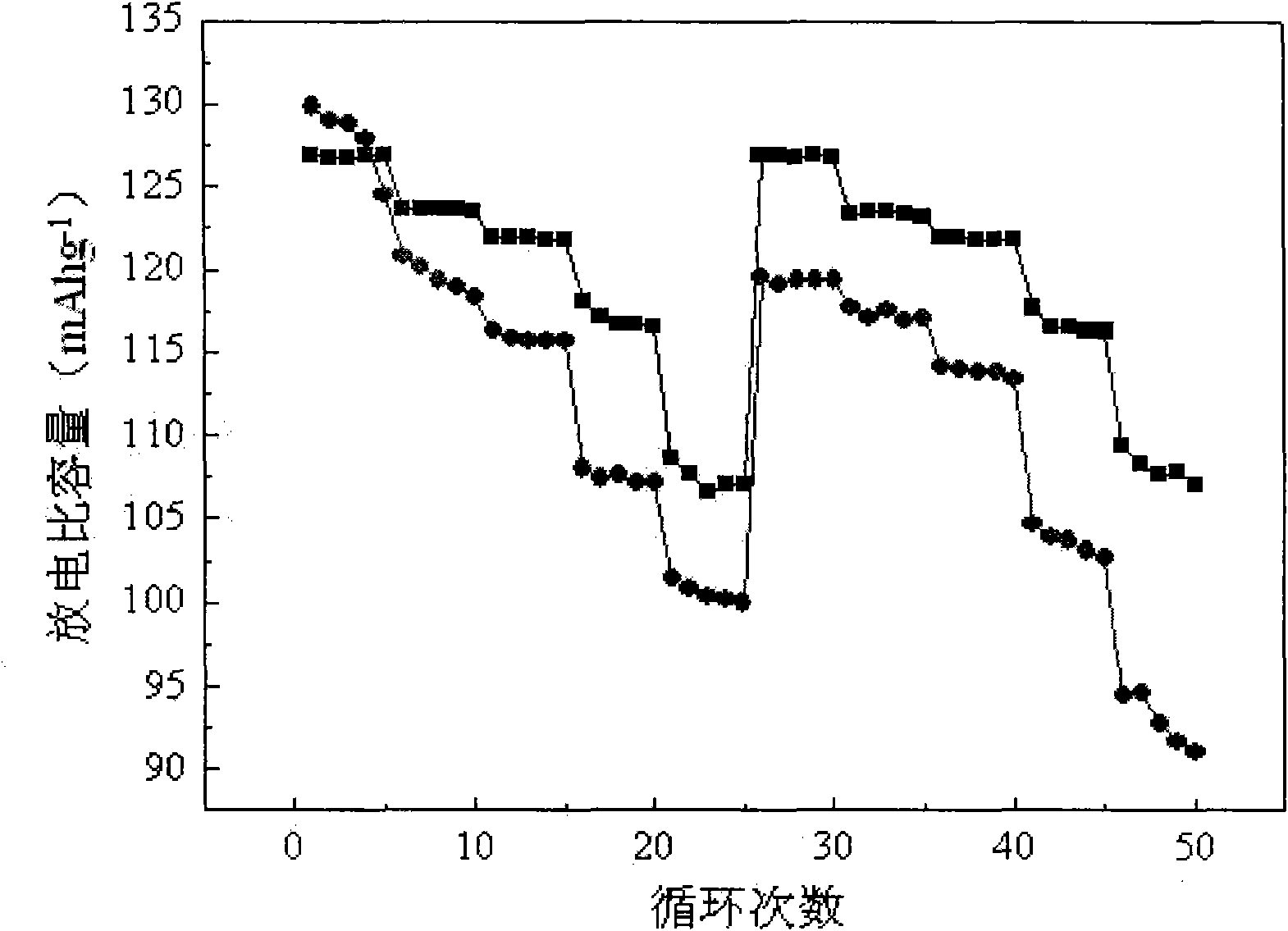

[0011] Specific implementation mode one: in this implementation mode, improve lithium-ion battery cathode material LiNi 0.5 mn 1.5 o 4 The method of electrochemical performance is achieved by the following steps: Chromium nitrate (Cr(NO 3 ) 3 9H 2 O) dissolved in ethanol aqueous solution, then add LiNi 0.5 mn 1.5 o 4 , at room temperature, ultrasonic frequency 20 ~ 100kHz conditions ultrasonic dispersion 5min ~ 120min, chromium nitrate quality is LiNi 0.5 mn 1.5 o 4 Stir in a water bath at 50-70°C until the liquid phase disappears, then calcinate at 800-900°C for 0.5-10h, cool naturally, and in LiNi 0.5 mn 1.5 o 4 The surface layer of the positive electrode material is doped with Cr 3+ , that is, the lithium-ion battery cathode material LiNi with high electrochemical performance is obtained 0.5 mn 1.5 o 4 wherein the volume concentration of the aqueous ethanol solution is 50% to 95%, and the mass ratio of the chromium nitrate to the aqueous ethanol solution is 1...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that: the ultrasonic frequency is 28-80 kHz. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment is different from Embodiment 1 in that: the ultrasonic frequency is 40 kHz. Other steps and parameters are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com