Miniature piezoelectric monocrystal linear motor

A technology of piezoelectric single crystal and linear motors, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of vibration sensitivity and low efficiency of the vibration system, Reach the effect of reducing the working voltage, avoiding the preparation process and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

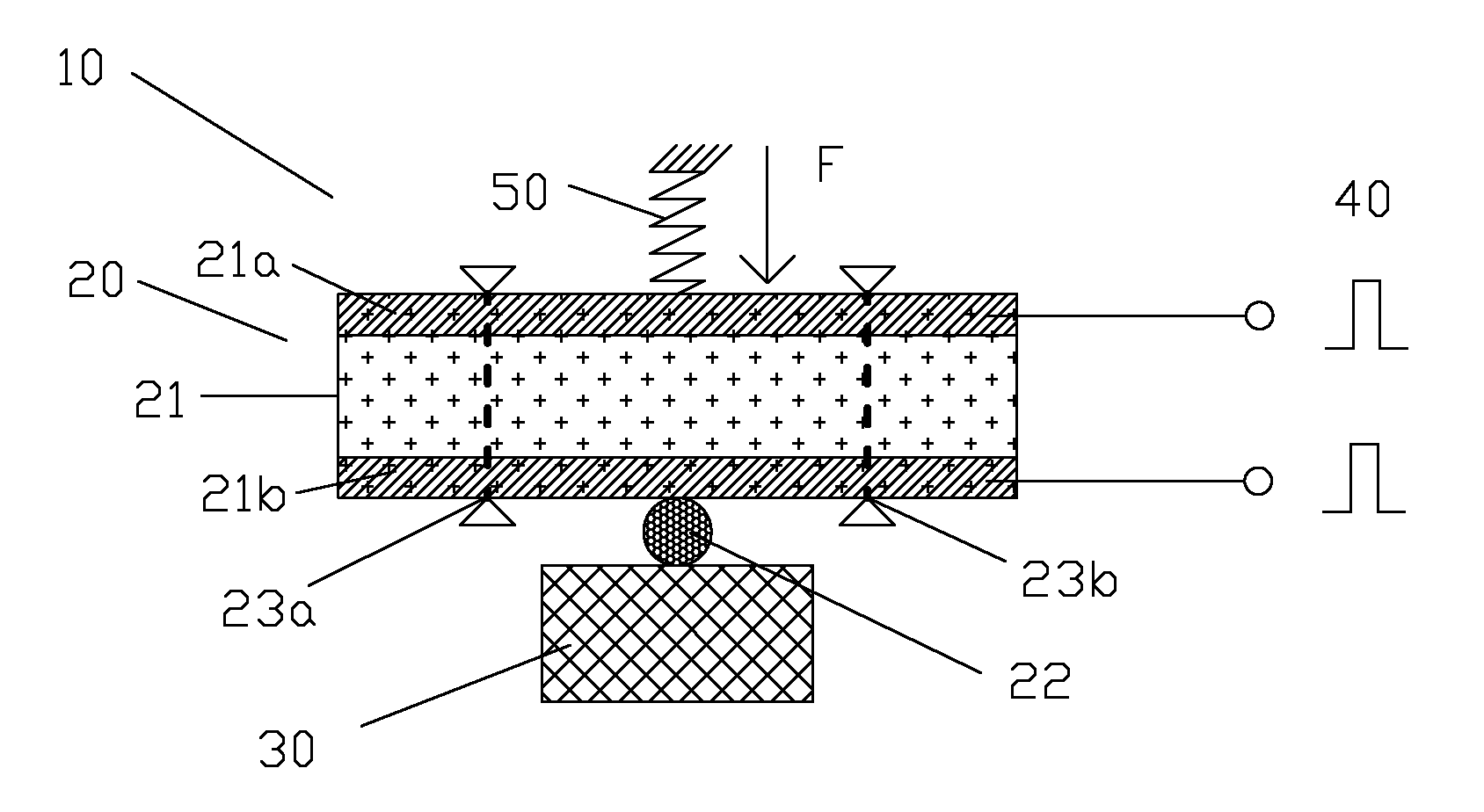

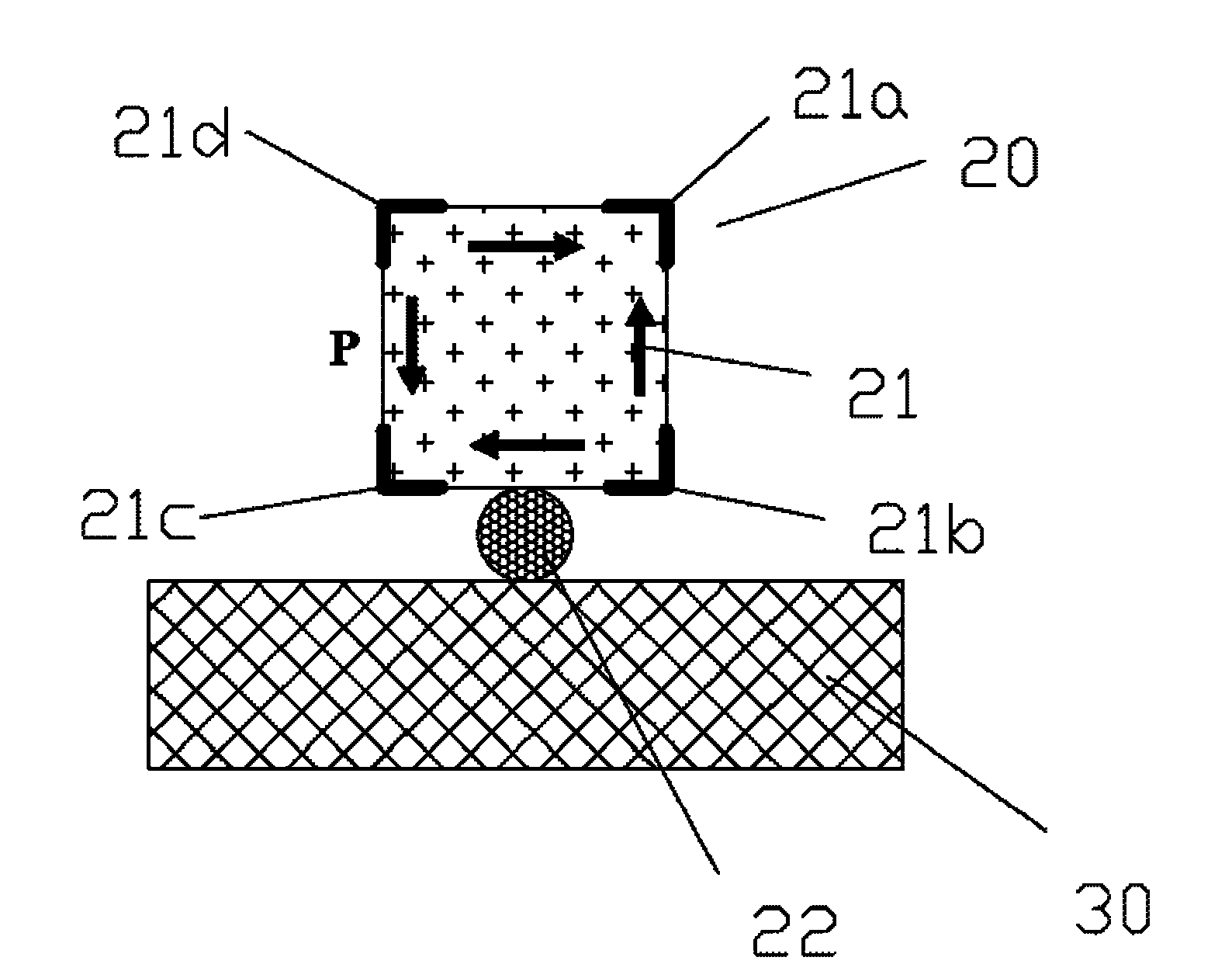

[0026] Depend on figure 1 It can be seen that the miniature piezoelectric single crystal linear motor 10 shown has a piezoelectric driver 20, which is made of a square columnar piezoelectric single crystal 21, and is bonded at the center of the lower surface of the piezoelectric single crystal 21 A friction block 22. The friction block 22 can also be a spherical, hemispherical, short rod-shaped, or square-shaped wear-resistant material, which is bonded and compounded with the piezoelectric single crystal 21 through epoxy resin. The motor 10 also includes a slider 30 . The main plane of the sliding block 30 is parallel to the plane where the friction block 22 is located, and the sliding direction of the sliding block 30 is defined in a direction perpendicular to the length of the piezoelectric single crystal 21 . The frictional contact between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com