Environment-friendly ultrasonic auxiliary extraction method of citrus carotenoids

A carotene and auxiliary extraction technology, applied in the field of food processing, can solve the problems of low extraction rate and extraction efficiency, expensive equipment, non-polar solvent toxicity, etc., and achieve the effects of high extraction rate, high efficiency and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

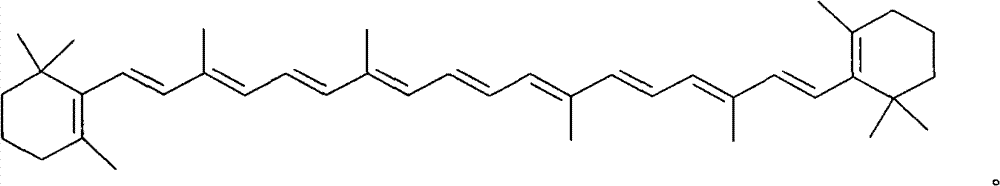

[0026] Embodiment 1, a kind of green ultrasonic-assisted extraction method of beta-carotene in local early citrus peel, carries out following steps successively:

[0027] 1), the processing of extracting raw materials:

[0028] With 500 grams of local early citrus peels as raw material, the raw material was vacuum-dried for 48 hours in an oven at 45°C. At this time, the water content in the local early citrus peels was determined to be 10% (weight ratio) with a moisture meter; stop vacuum drying, The dried raw material is obtained; the dried raw material is ground with a pulverizer, and the obtained raw material powder is first passed through a 20-mesh sieve and then passed through a 60-mesh sieve. Store for later use.

[0029] 2) Put 3g of raw material powder into a brown flat-bottomed glass tube, add 30ml of ethanol according to the ratio of raw material powder: ethanol is 3g / 30ml, and obtain the extracted stock solution.

[0030] 3), use the probe-type pulsed ultrasonic w...

Embodiment 2

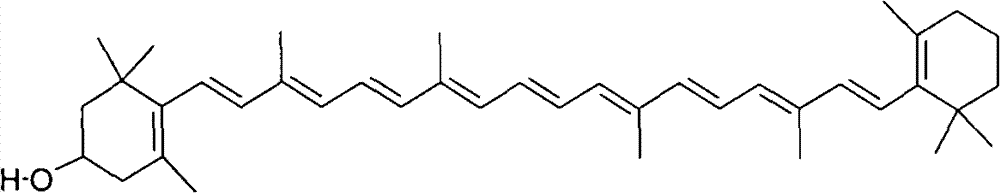

[0038] Embodiment 2, a green ultrasonic-assisted extraction method of β-cryptoxanthin in citrus peel of Wenzhou mandarin orange, carries out the following steps successively:

[0039] 1), the processing of extracting raw materials:

[0040] With 500 grams of Wenzhou Satsuma citrus peels as raw material, the raw material was vacuum-dried for 48 hours in a 45° C. oven. At this time, the moisture content measured in the local early orange peels with a moisture meter was 11% (weight ratio); stop vacuum drying, The dried raw material is obtained; the dried raw material is ground with a pulverizer, and the obtained raw material powder is first passed through a 20-mesh sieve and then passed through a 60-mesh sieve. Store for later use.

[0041] 2) Put 3 g of raw material powder into a brown flat-bottomed glass tube, add 30 ml of ethanol according to the ratio of raw material powder: ethanol of 3 g / 30 ml, and obtain the extracted stock solution.

[0042] 3) Use probe-type pulsed ult...

Embodiment 3

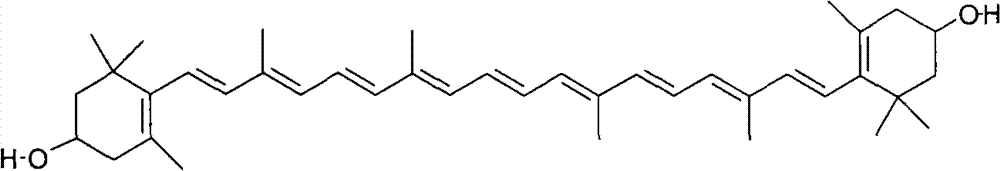

[0050] Embodiment 3, a kind of green ultrasonic assisted extraction method of lutein in Wenzhou mandarin tangerine peel, carries out following steps successively:

[0051] 1), the processing of extracting raw materials:

[0052] With 500 grams of Wenzhou Satsuma citrus peels as raw material, the raw material was vacuum-dried for 48 hours in a 45° C. oven. At this time, the moisture content measured in the local early orange peels with a moisture meter was 11% (weight ratio); stop vacuum drying, The dried raw material is obtained; the dried raw material is ground with a pulverizer, and the obtained raw material powder is first passed through a 20-mesh sieve and then passed through a 60-mesh sieve. Store for later use.

[0053] 2) Put 3 g of raw material powder into a brown flat-bottomed glass tube, add 30 ml of ethanol according to the ratio of raw material powder: ethanol of 3 g / 30 ml, and obtain the extracted stock solution.

[0054] 3) Use probe-type pulsed ultrasonic wave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com