PC/ABS alloy with good-appearance high-intensity weld line and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

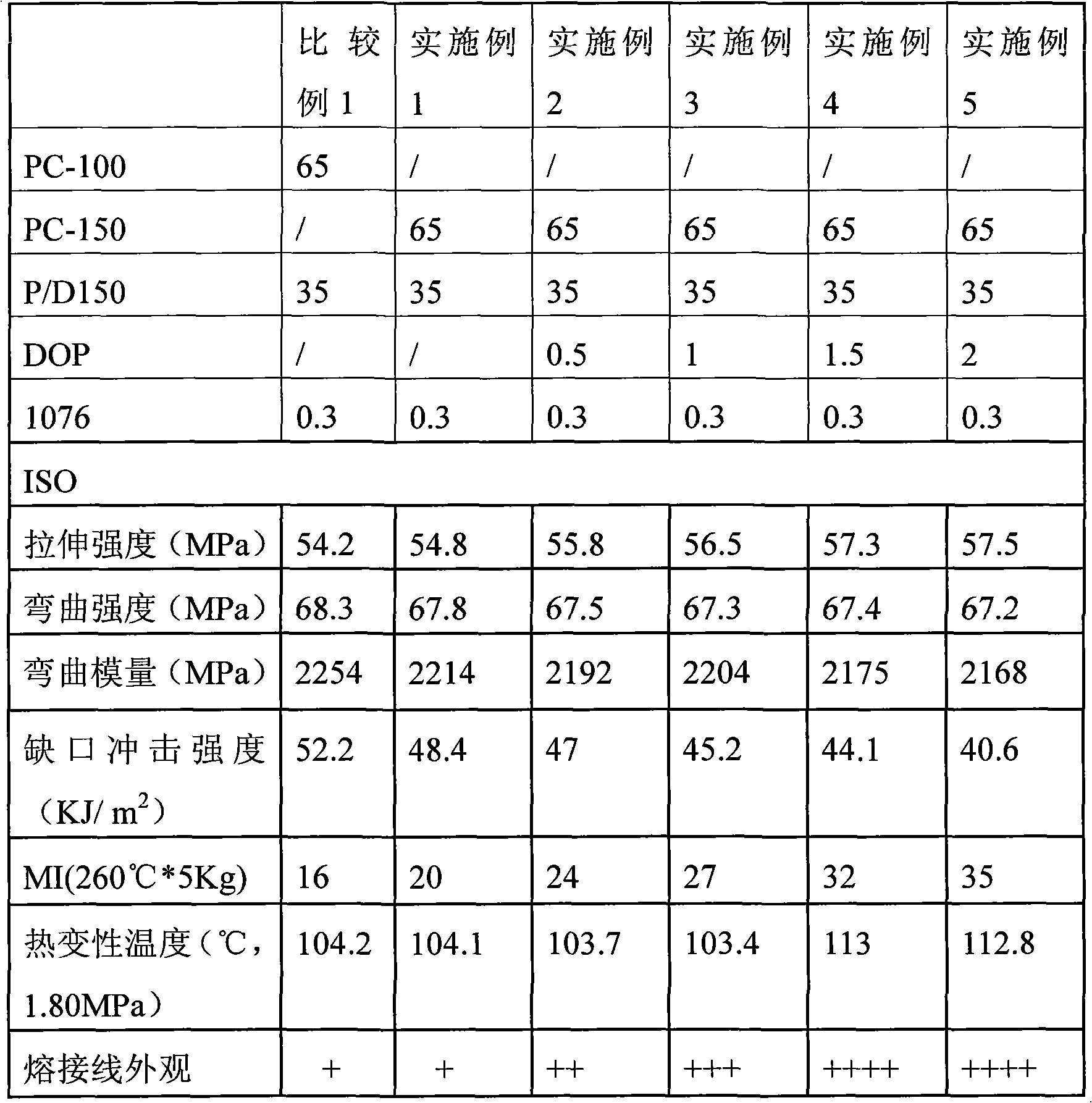

Method used

Image

Examples

Embodiment 6

[0023] A method for preparing a PC / ABS alloy with good weld line appearance and high strength. The method is to prepare 50 parts by weight of bisphenol A polycarbonate with a molecular weight of 20,000, 40 parts by weight of ABS, and acrylate- 10 parts by weight of butadiene-styrene (MBS), 10 parts by weight of dioctyl phthalate (DOP), 0.5 parts by weight of antioxidant (1010), 0.5 part by weight of antioxidant (168) placed in medium speed In a mixer, mix for 30 minutes to obtain a mixed material, put the mixed material into a twin-screw extruder, control the screw speed at 600 rpm, melt and extrude, and granulate to obtain the product.

[0024] The molecular weight of the ABS is 80000, wherein the rubber content is 5wt%, the acrylonitrile content is 30wt%, and the styrene content is 65wt%.

[0025] The twin-screw extruder includes 10 temperature control zones, the temperature of temperature control zone 1-2 is 180-260°C, the temperature of temperature control zone 3-4 is 180-...

Embodiment 7

[0027] A method for preparing a PC / ABS alloy with good weld line appearance and high strength. The method is to prepare 70 parts by weight of bisphenol A polycarbonate with a molecular weight of 25,000, 30 parts by weight of ABS, and 80% of acrylate- 5 parts by weight of butadiene-styrene (MBS), 1 part by weight of dibutyl phthalate (DBP), and 0.1 part by weight of antioxidant (1010) are placed in a medium-speed mixer and mixed for 10 minutes to obtain a mixed material , put the mixed material in a twin-screw extruder, control the screw speed to 180rpm, melt extrusion, and granulate to obtain the product.

[0028] The molecular weight of the ABS is 150000, wherein the content of rubber is 30wt%, the content of acrylonitrile is 30wt%, and the content of styrene is 40wt%.

[0029] The twin-screw extruder includes 10 temperature control zones, the temperature of temperature control zone 1-2 is 180-260°C, the temperature of temperature control zone 3-4 is 180-260°C, and the temper...

Embodiment 8

[0031] A method for preparing a PC / ABS alloy with good weld line appearance and high strength. The method comprises 58 parts by weight of bisphenol A polycarbonate with a molecular weight of 23,000, 36 parts by weight of ABS, and acrylic acid with a rubber content of 60-80%. 8 parts by weight of ester-butadiene-styrene (MBS), 6 parts by weight of bisphenol A bisdiphenyl phosphate (BDP), 0.5 parts by weight of antioxidant (1076) were placed in a medium-speed mixer, and mixed for 20 minutes , to obtain the mixed material, put the mixed material into a twin-screw extruder, control the screw speed to 230rpm, melt extrude, and granulate to obtain the product.

[0032] The molecular weight of the ABS is 100000, wherein the rubber content is 20wt%, the acrylonitrile content is 10wt%, and the styrene content is 70wt%.

[0033] The twin-screw extruder includes 10 temperature control zones, the temperature of temperature control zone 1-2 is 180-260°C, the temperature of temperature cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com