Intelligent electrophoresis temperature control tank and time temperature-gel gradient electrophoresis system

An intelligent electrophoresis and intelligent technology, applied in the direction of material analysis by electromagnetic means, biochemical equipment and methods, instruments, etc., can solve the problems that the DGGE electrophoresis system cannot perform TTGG electrophoresis, the heating rate is different, and the heating rate cannot be adjusted according to needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

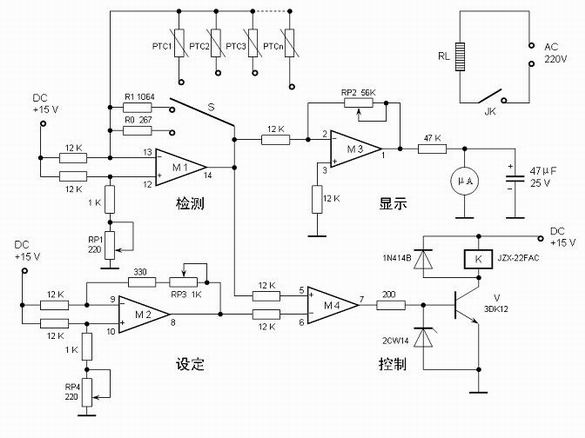

[0037] 1.1 Technical route

[0038] Use a 0.22 μm filter membrane to filter lake water samples → extract bacterial DNA from the filter membrane → PCR amplification (forward primer 341F and reverse primer 907R for bacterial 16SrDNA sequence) → analysis of the melting temperature of the amplification product and its TTGG temperature condition setting → TTGG→Gel photography, band analysis.

[0039] The process of "Amplification Product Melting Temperature Analysis→TTGG" will be introduced in detail below.

[0040] 1.2 Fusion chain analysis of amplified products

[0041] Input the PCR primer sequence into the computer of the system, and the software attached to the computer will predict the sequence of the PCR product after analysis and calculate the melting curve to obtain the initial temperature and target temperature of TTGG, and set the heating time and heating speed according to the difference between the two temperatures Usually between 0.5°C / hour and 3°C / hour. Generally, ...

Embodiment 2

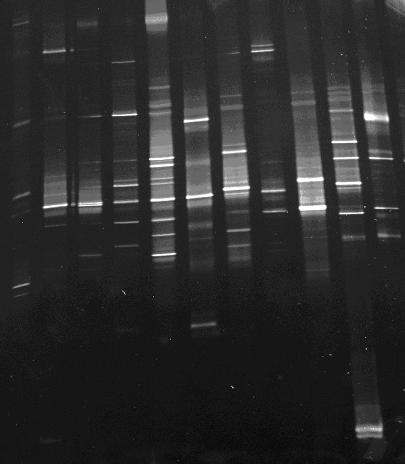

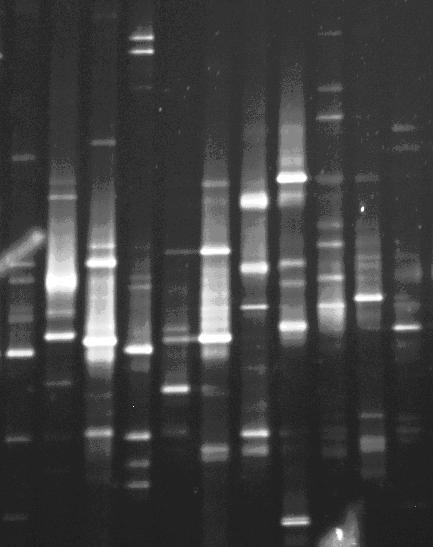

[0053] The same 11 samples were equally divided into two parts, one part was subjected to TTGG electrophoresis according to the above steps of the present invention (Table 3), and the other part was subjected to DGGE electrophoresis (Table 4, the system used refers to ZL200820037544.5), and then the two electrophoresis patterns were analyzed Compare.

[0054]

[0055]

[0056] The result is as figure 2 and image 3 Shown, the TTGG electrophoretic pattern of the present invention ( figure 2 ) with clear bands, rich diversity and high resolution; DGGE electrophoresis pattern ( image 3 ) with blurred bands and low resolution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com