Plasma etching method for etching organic matter layer

An organic and plasma technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of uneven etching morphology in the middle area and edge area, bow shape in the edge area of the substrate, etc., and achieve uniform etching effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

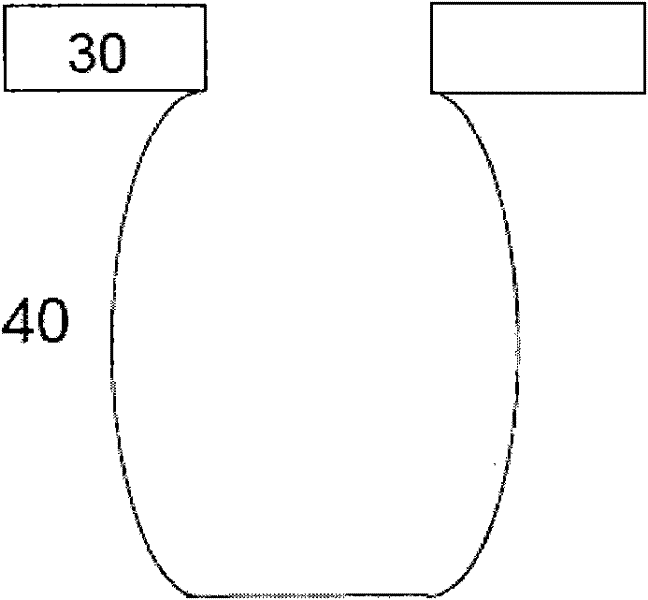

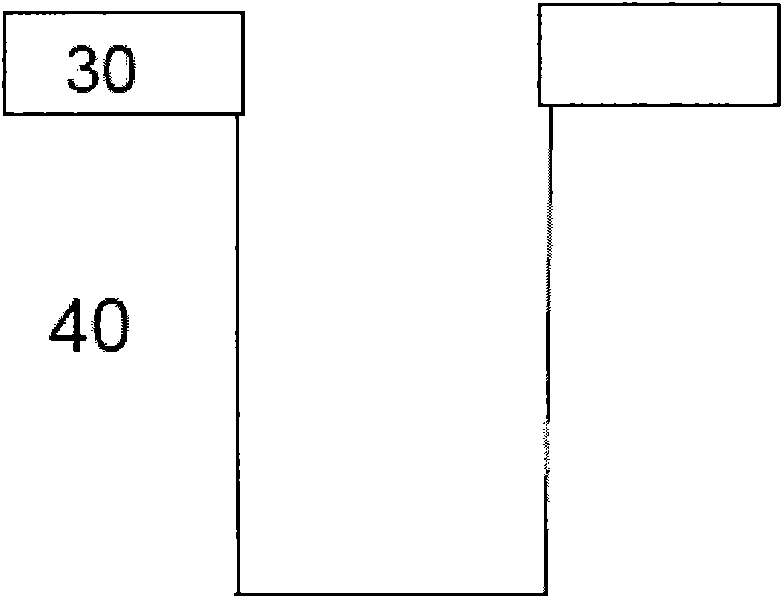

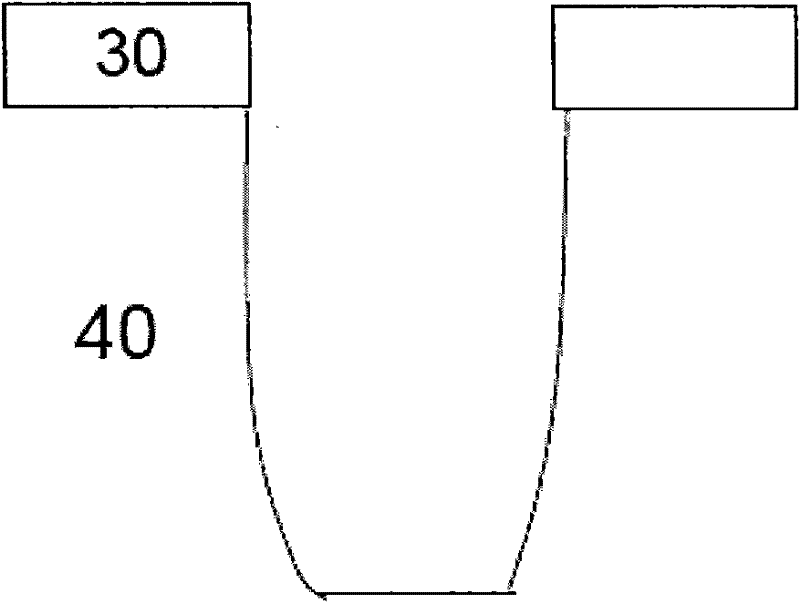

[0018] In the prior art, a mixed etching gas and a sidewall protection gas are used for etching, and the etching gas is one of oxygen-containing gases such as O2, CO2, and CO or a mixed gas. The sidewall protection gas may be a sulfur-containing gas (such as COS), which can form a solid protective layer on the sidewall formed by etching the carbon-containing layer, preventing the sidewall from being etched and forming a bow. The sidewall shielding gas can also be a polymer forming gas (such as hydrocarbon or fluorocarbon) to form a thick enough polymer on the etched sidewall. Due to the limitation of the hardware structure of the etching reaction chamber, there will inevitably be uneven plasma density between the central area and the edge area of the substrate (high in the middle and low at the edge), and the edge area will also be affected by the exhaust device to reduce the gas concentration. These factors all lead to different groove profiles formed by etching in the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com