Compound lathe and workpiece processing method

A processing method and lathe technology, applied in the field of compound lathes, can solve the problems of complex structure, high spindle position, and different processing of two difficult workpieces, and achieve the effect of reasonable configuration and improved support rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

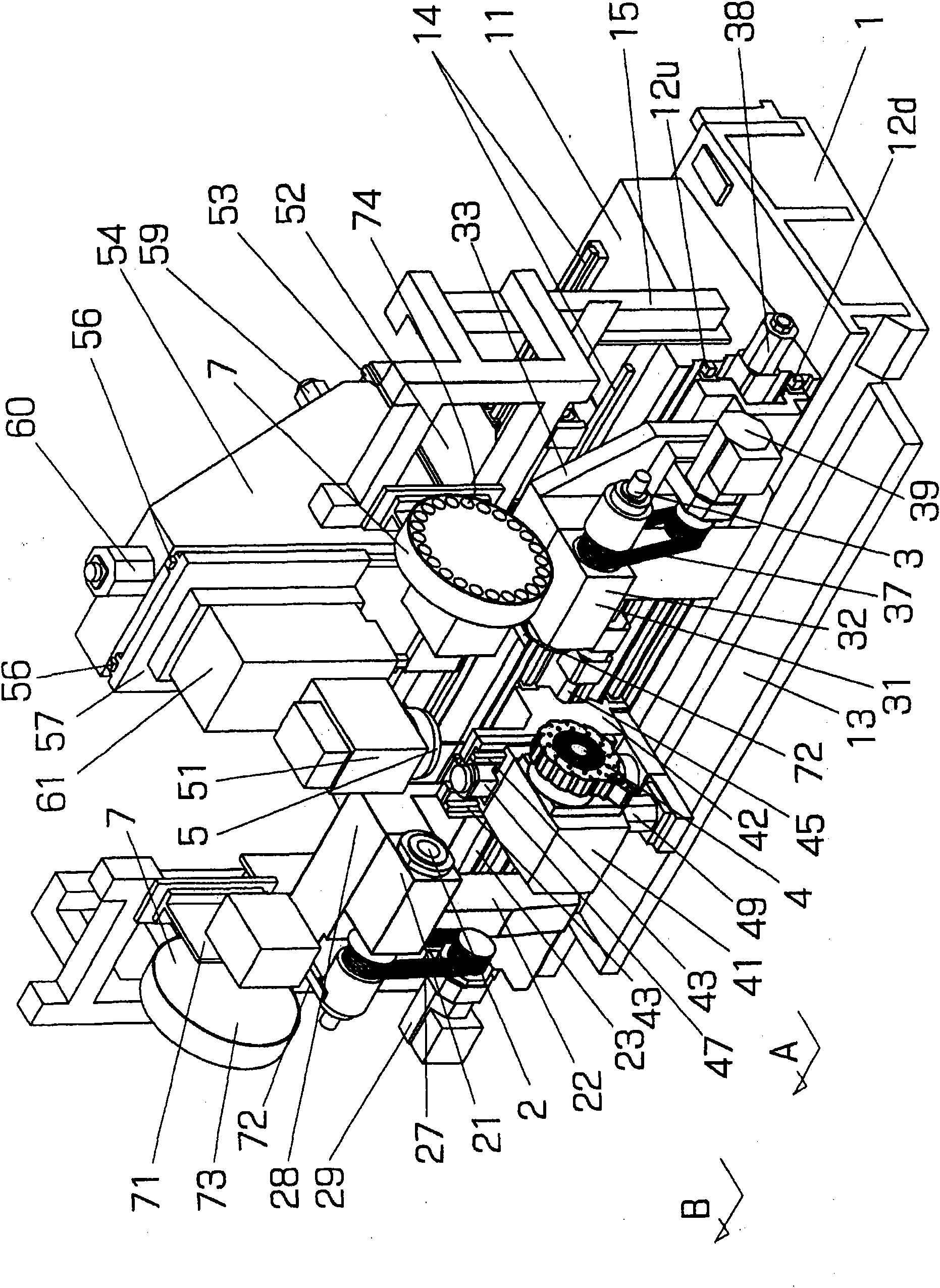

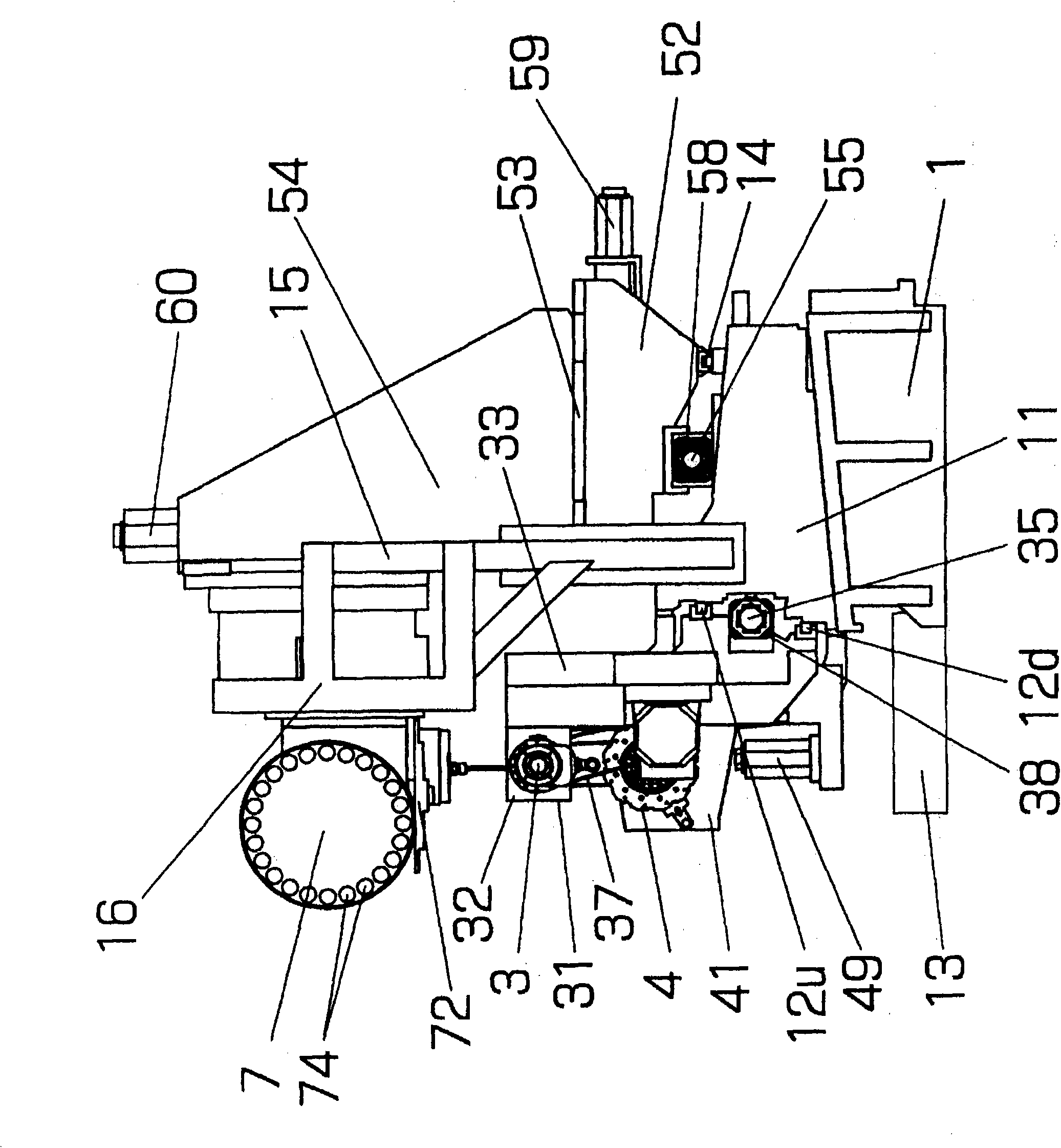

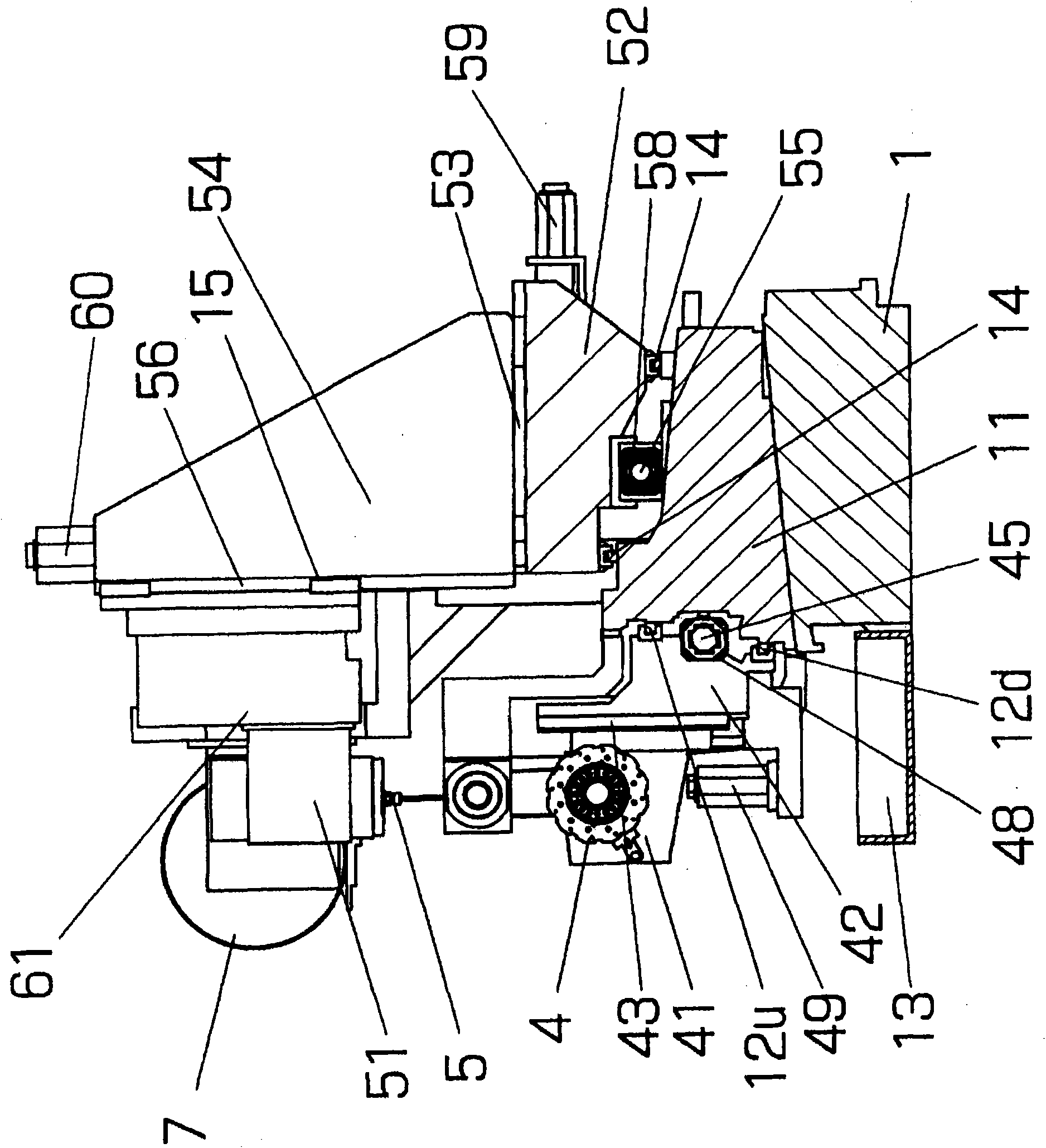

[0041] Next, specific examples of the present invention will be described with reference to the drawings. The accompanying drawing is a double-spindle opposed compound lathe with the structure of the present invention, which includes: two main shafts 2 and 3 facing each other on the same axis a; a tool shaft 5 arranged directly above the main shaft axis; and a tool shaft 5 arranged on the main shaft The tool turret 4 directly below the axis. The direction of the spindle axis a is the left-right direction when viewed from the operator side, the tool cutting direction of the tool shaft 5 and the tool turret 4 is the vertical direction, the direction orthogonal to these two directions is the front-rear direction, and the left and right are the Z-axis of the lathe , up and down is the X axis, front and rear is the Y axis, and the operator's side is the front.

[0042] Viewed from the operator's side, the left headstock 21 is fixed to the bed 11 , and the right headstock 31 can fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com