Anti-counterfeiting laser boring method and device of cigarette tipping paper

A technology of cigarette tipping paper and laser drilling, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., and can solve problems such as the method of punching micro-hole patterns on the surface of tipping paper, etc., and achieve beautiful appearance Changeable, fast punching speed, anti-counterfeiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

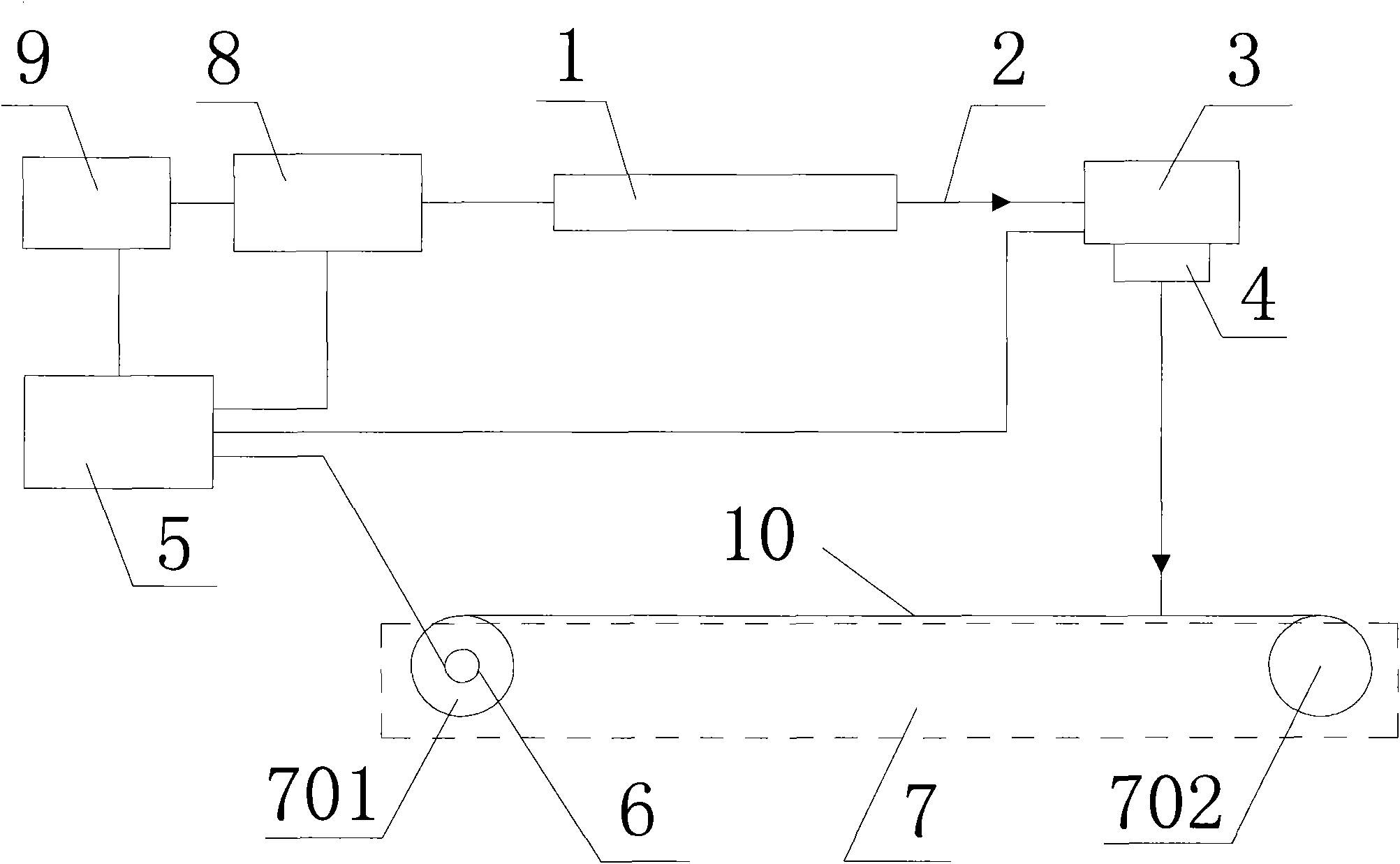

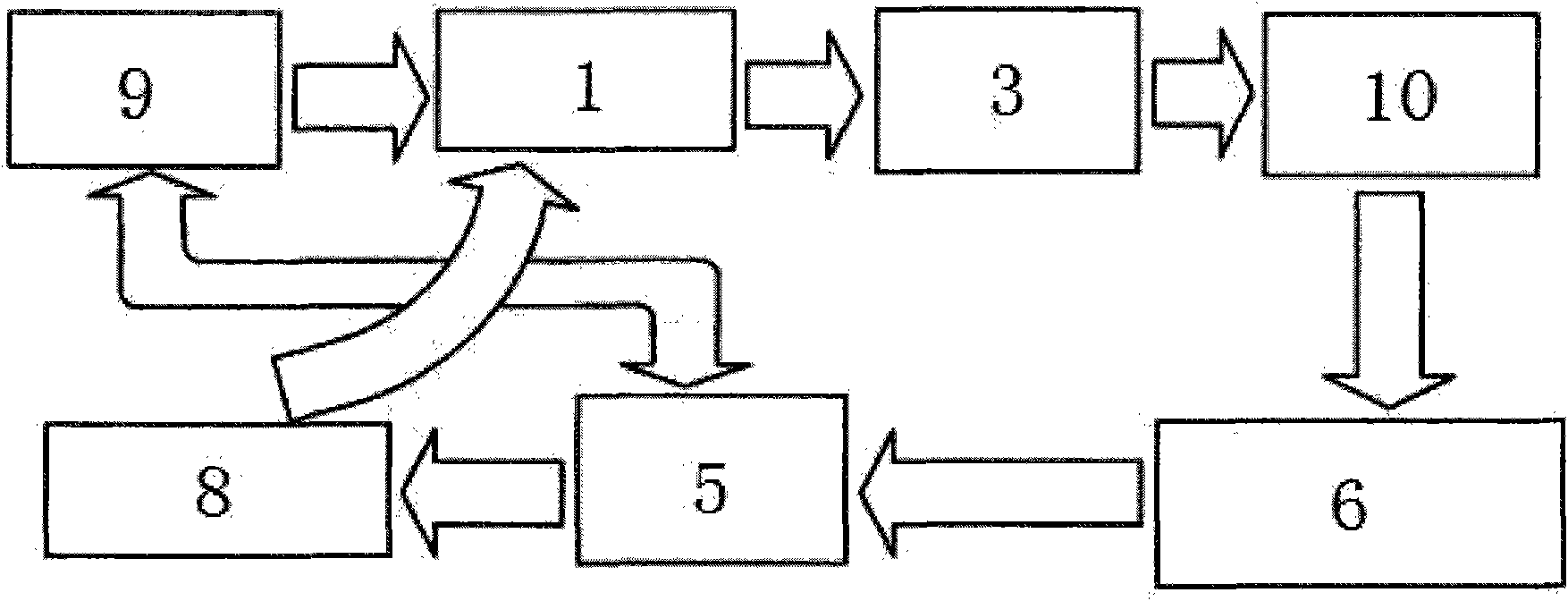

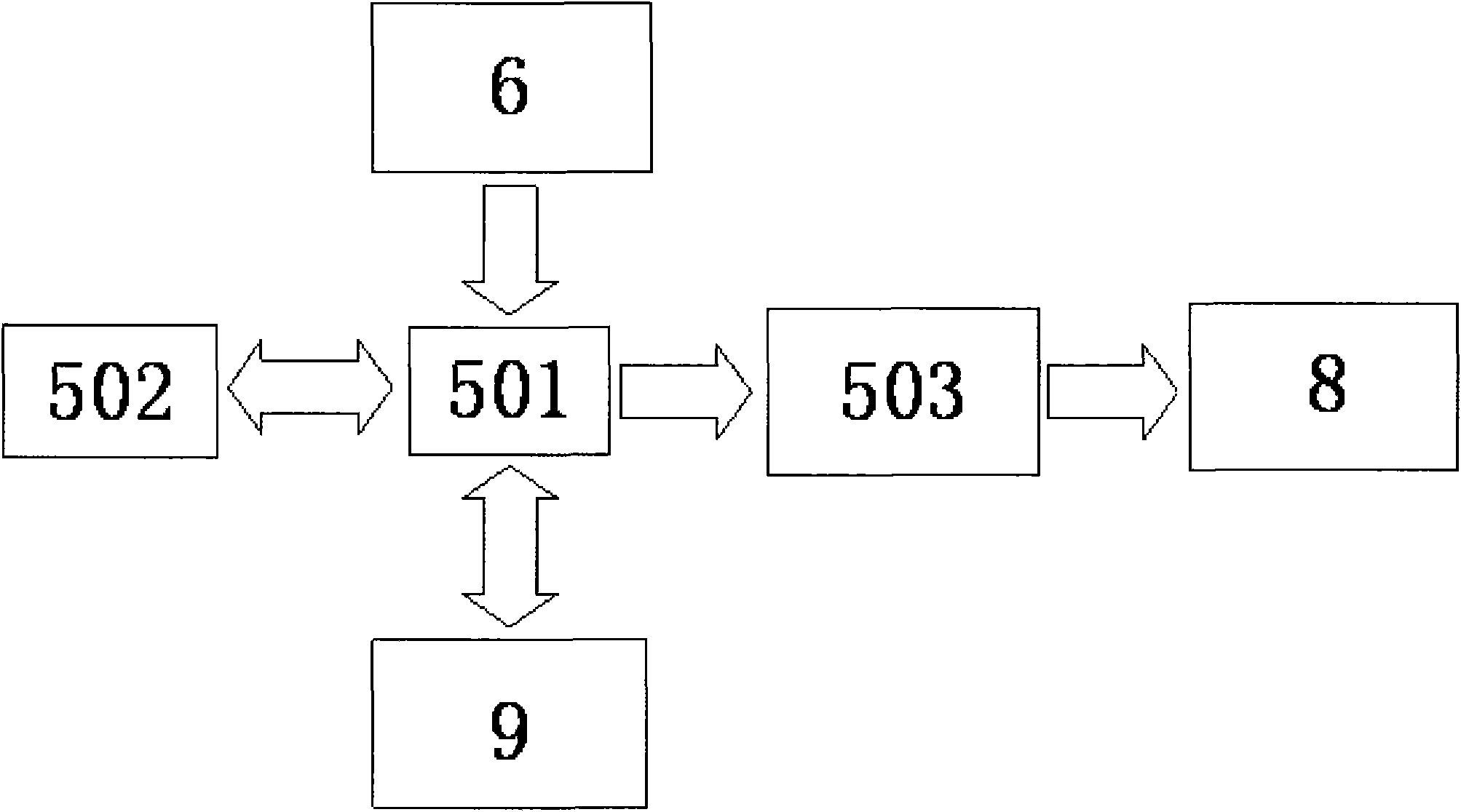

[0033] Example: Combine figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a specific embodiment of a cigarette tipping paper anti-counterfeiting laser drilling device, which consists of a pulse laser 1, a two-dimensional acousto-optic deflection system 3, an F-θ lens 4, a control system 5, The tipping paper online speed detection system 6, the pulse laser power supply 8, the laser cooling system 9 and the paper-feeding mechanism 7 that drives the tipping paper 10 to move continuously are composed together, wherein the pulse laser 1 is electrically connected to the control system 5 via the pulse laser power supply 8. connected, the paper feeding mechanism 7 is electrically connected to the control system 5, the paper feeding mechanism 7 in this embodiment includes a winding roller 701 and an unwinding roller 702, and the tipping paper 10 is clamped between the winding roller 701 and the unwinding roller 701. On the winding roller 702, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com