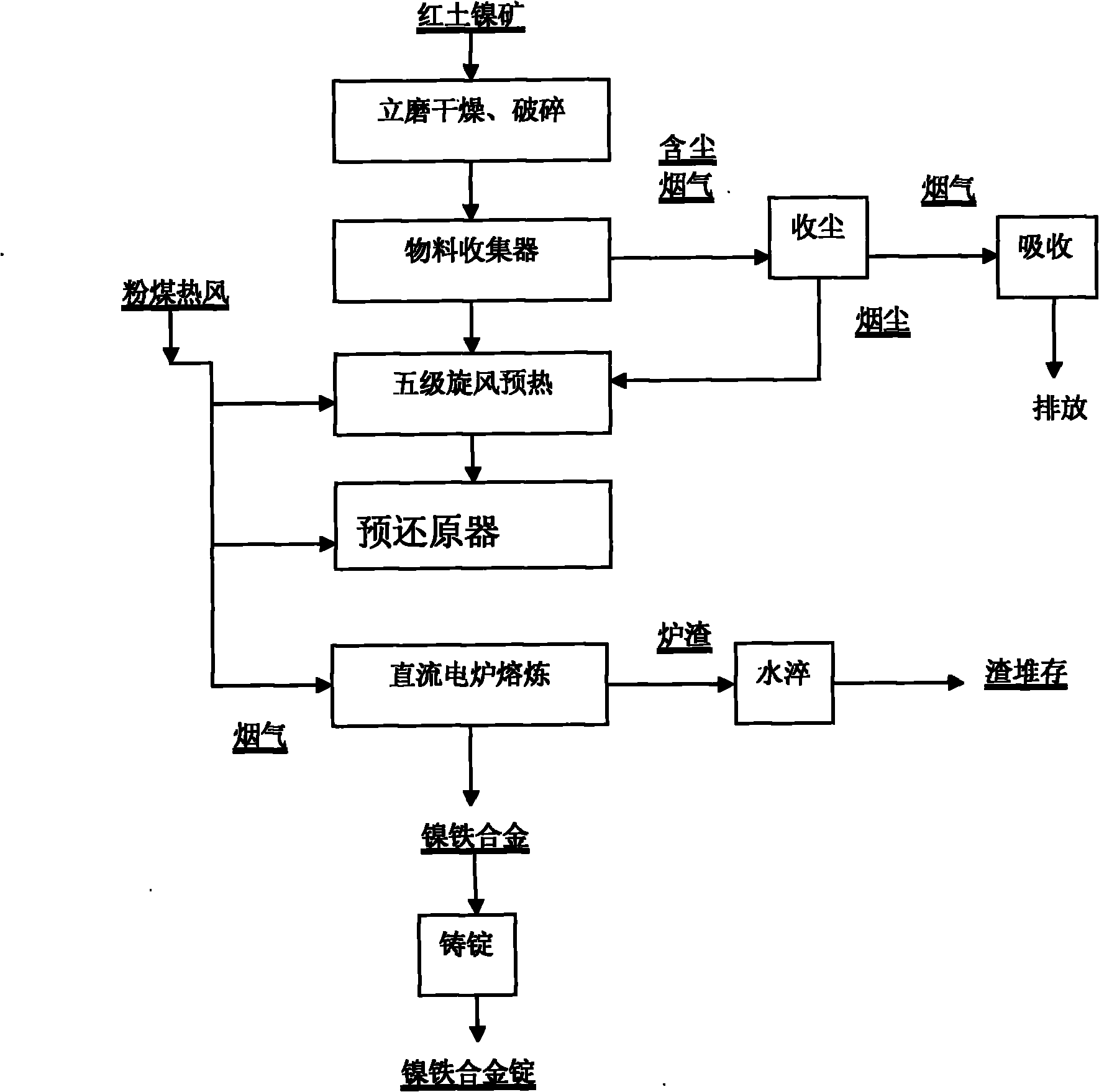

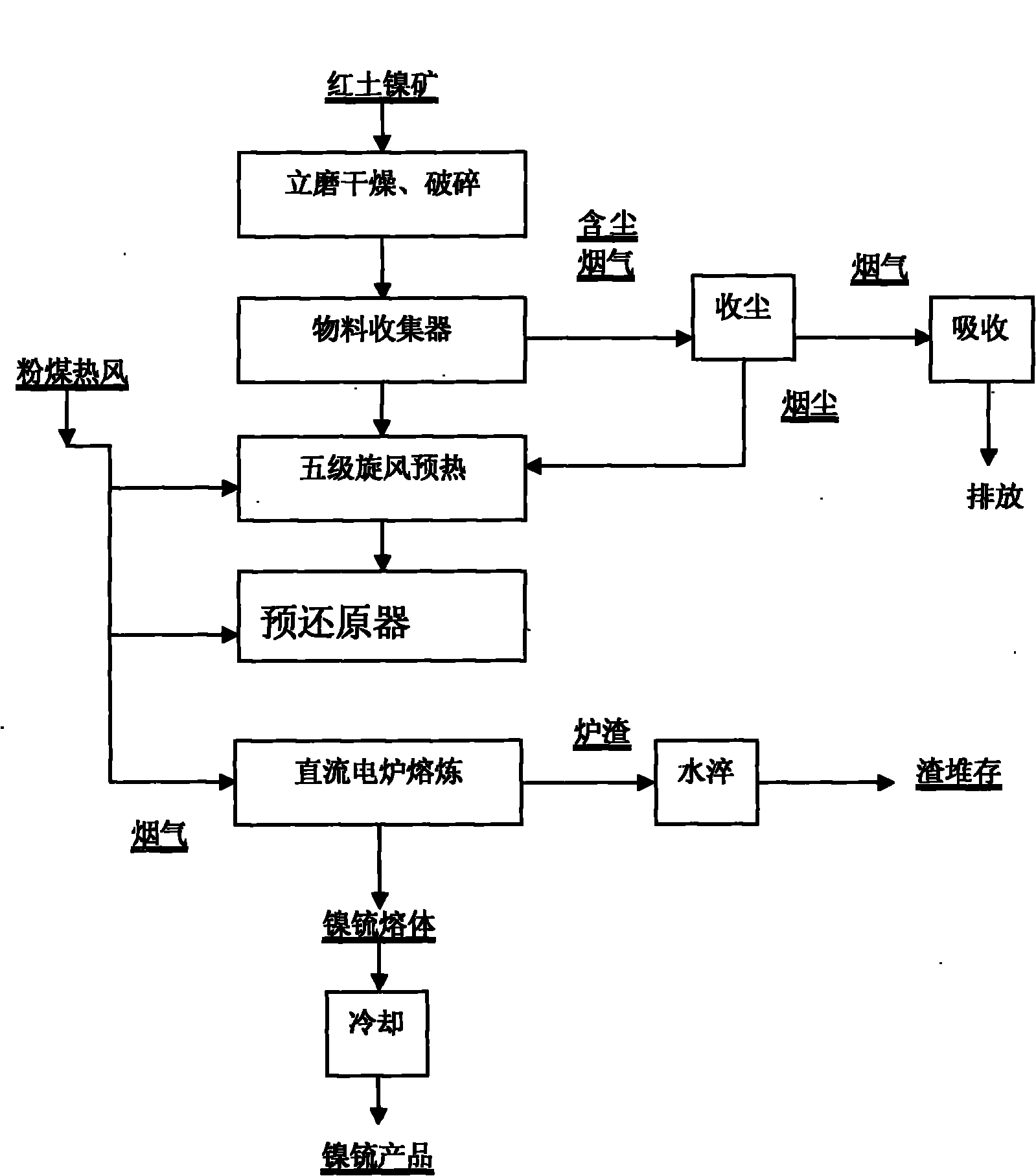

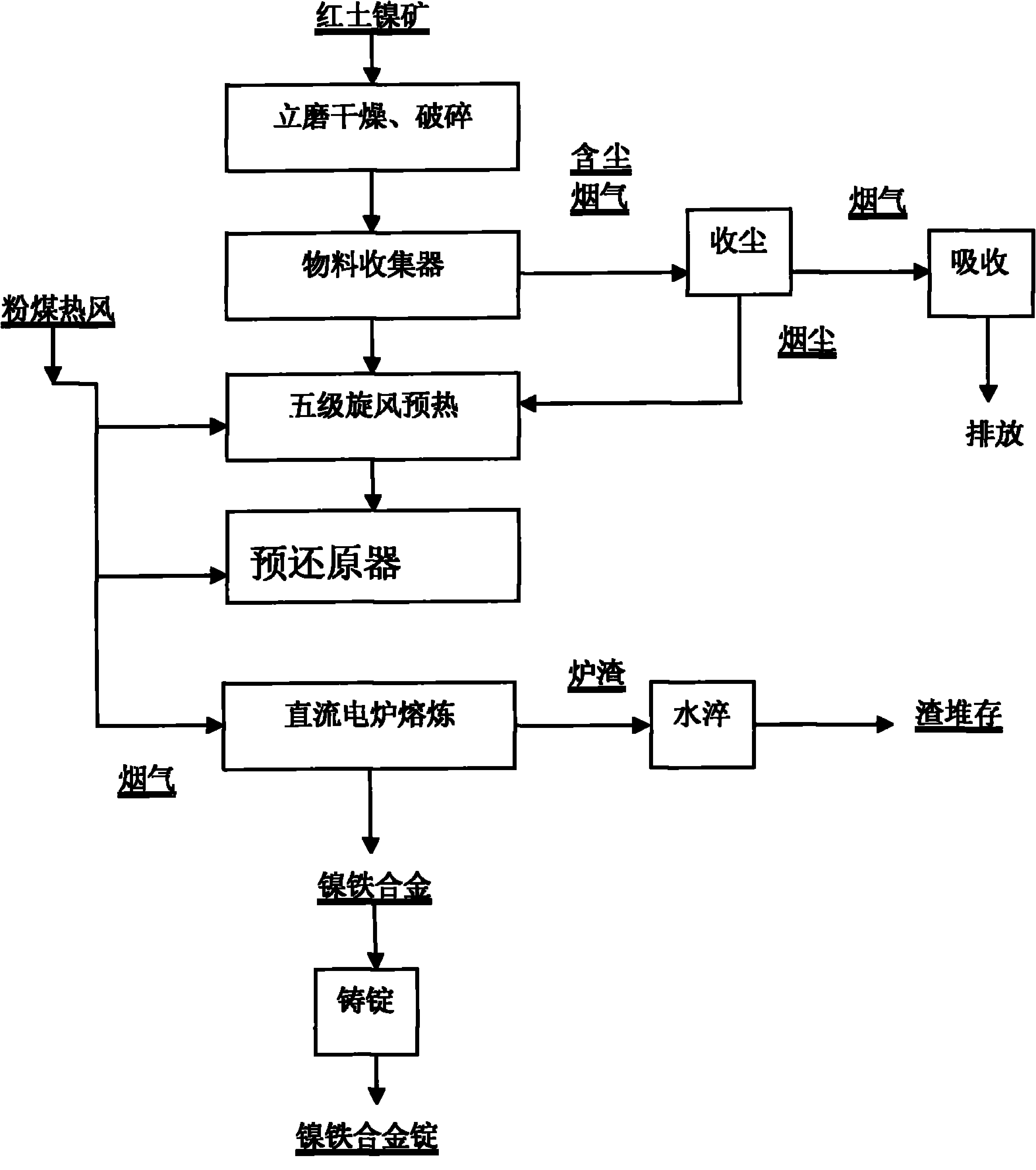

Method for smelting ferronickel or nismatte with laterite-nickel ore

A technology of laterite nickel ore and nickel matte, which is applied in the smelting process of laterite nickel ore, can solve the problems of large amount of ore, high energy consumption, and high smelting cost, achieve uniform furnace temperature, improve metal recovery rate, and invest per ton of nickel low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the steps are as follows:

[0021] A. The chemical composition of the laterite nickel ore used is as follows:

[0022] element

Ni

co

FeO

MgO

Al 2 o 3

SiO 2

CaO

content%

1.03

0.039

17.22

27.3

4.84

35.72

0.32

[0023] The ore directly extracted from the stope has a water content of 25%, and the blocky ore > 100mm is removed by a strip sieve (crushed by a crusher < 100mm and then enters the vertical mill), and the underscreen material enters the vertical mill for drying and crushing.

[0024] B. Use the 3-stage suspension drying and calcining device to output the flue gas with a temperature of 300°C into the vertical mill for drying. After the vertical mill is crushed, the particle size of the material is 0.2mm and the moisture content of the material is 10%. After being collected by a cyclone and a bag filter, it enters 3 Level suspension drying calciner.

[0025] C...

Embodiment 2

[0028] Embodiment 2 steps are as follows:

[0029] The first step is the same as step A of Example 1.

[0030] A. Use the 5-stage suspension drying and calcining device to output the flue gas with a temperature of 250°C into the vertical mill for drying. After the vertical mill is crushed, the particle size of the material is 0.6mm and the moisture content of the material is 15%. Level suspension drying calciner.

[0031] B. In the fifth-stage suspension drying and calcination device, the high-temperature flue gas with a temperature of 1100°C produced by the combustion of materials and pulverized coal fuel is subjected to countercurrent suspension heat exchange, and the residence time of the materials is 4 minutes, and the materials with a temperature of 750°C are produced from the fifth-stage suspender After entering the pre-reducer, the flue gas with a temperature of 250°C from the first stage enters the vertical mill.

Embodiment 3

[0034] Embodiment 3 steps are as follows:

[0035] The first step is the same as step A of Example 1.

[0036] A. Use the 7-stage suspension drying and calcining device to output the flue gas with a temperature of 200°C into the vertical mill for drying. After the vertical mill is crushed, the particle size of the material is 0.8mm, and the material moisture is 17%. It is collected by a cyclone and a bag filter and then enters the 7 Level suspension drying calciner.

[0037] B. In the 7-stage suspension drying and calcination device, the high-temperature flue gas with a temperature of 1100°C produced by the combustion of materials and pulverized coal fuel is subjected to countercurrent suspension heat exchange. The residence time of the materials is 6 minutes, and the materials with a temperature of 800°C are produced from the seventh-stage suspender. Entering the pre-reducer, the flue gas with a temperature of 200°C from the first stage enters the vertical mill.

[0038] C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com