Multilayer corrosion-resistance coating and part comprising same

A corrosion-resistant coating and coating technology, used in coatings, anti-corrosion coatings, layered products, etc., can solve problems such as difficulty in meeting corrosion resistance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

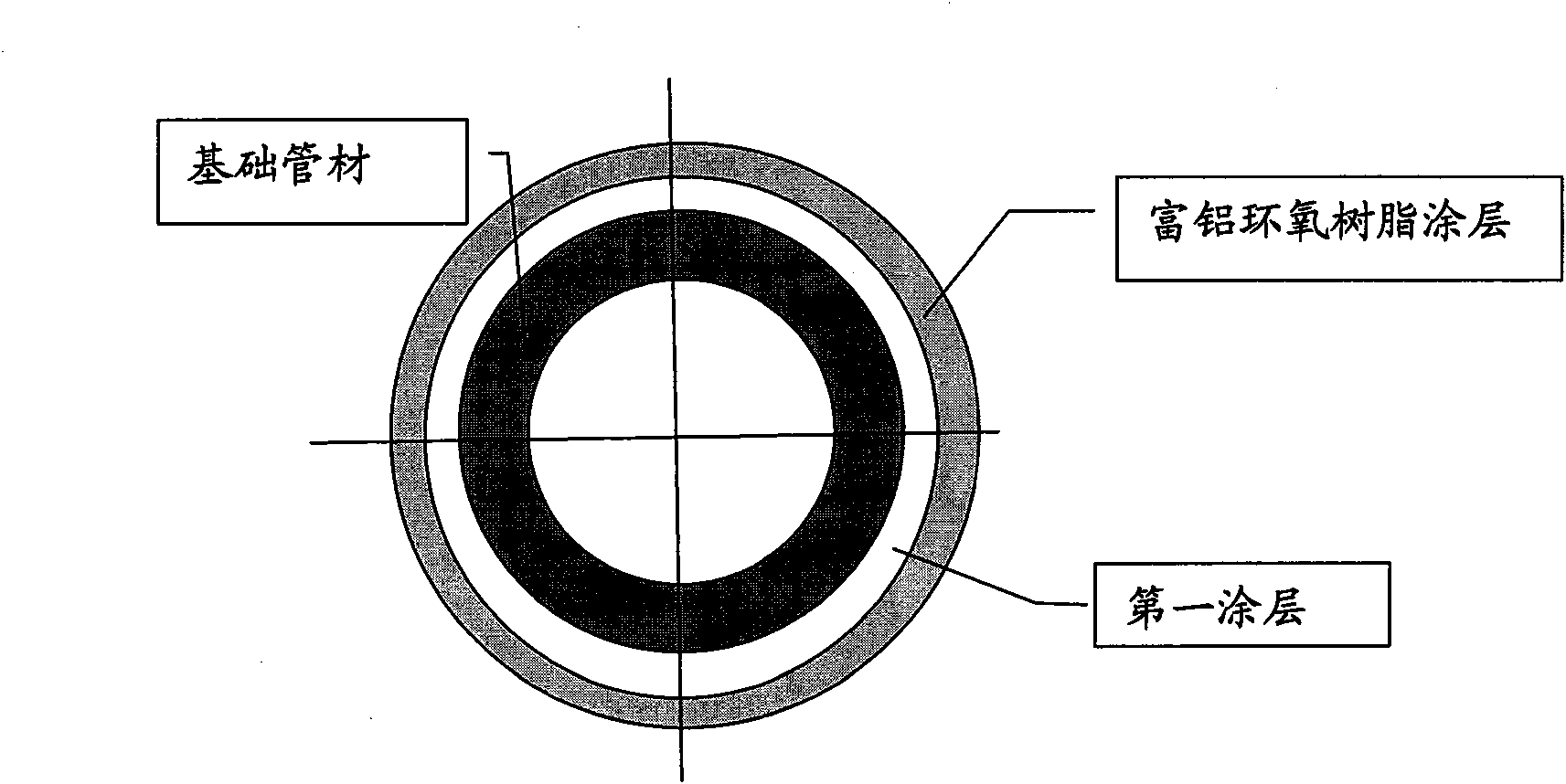

[0032] Two-layer coating tests were tested using a 4.76 DW double-layer pipe: the first coat was applied followed by an aluminum-rich epoxy (commercially available) coat. The minimum thickness of the first coating is 3 microns, and the average coating weight is 50-60g / m 2 , the minimum thickness of subsequent aluminum-rich epoxy coating is 3 microns, and the average weight is ≥10g / m 2 . After the coating is completed, a series of test verifications are carried out, and the verification report given by the TI Automotive (China) laboratory is shown in Table 1 below:

[0033] Table 1

[0034]

Embodiment 2

[0036] In order to further verify the coating performance, four kinds of pipes of 4.76DW / 6.35DW / 6.35SW / 7.94SW were arranged for online expansion test. After the test was completed, a series of verification was carried out. TI Automotive (China) laboratory gave a verification report as shown in Table 2. Show:

[0037] Table 2

[0038]

[0039] The results of repeated expansion tests show that this multi-layer corrosion-resistant coating pipe has excellent anti-corrosion performance.

Embodiment 3

[0041] In order to further verify the machinability of the coated pipe, bending forming and flaring tests were arranged for the coated pipes of the above-mentioned examples 1 and 2, and the results met the A0005-115 degree flaring test and the Z183-90 degree double flaring test Require. Forming flaring pictures such as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com